2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:11

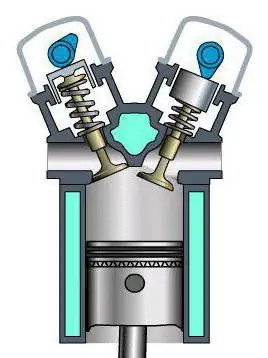

What is compression? This is the pressure in the combustion chamber at the end of the compression stroke. It can be bled through the piston rings or through the valve train. In the first case, repair involves only replacement, and in the second, it is quite possible to do without it. Consider such situations on the example of a VAZ engine.

First of all, it is worth saying that this procedure is called "lapping the valves". During operation, carbon deposits form on the valve seats, which prevents them from completely closing. Thus, lapping the valves avoids this malfunction. How can you tell if they need lapping? The answer is simple. If the compression in the cylinders has dropped, then such an operation is simply necessary. The fact is that lapping of valves is needed for such engines, the resource of which is already a little exhausted, and the unit is far from full of energy.

Initially, a gap is formed between the seat and the valve band due to the wear of the latter. Since the "cotton" when closing is quite strong, over time the edge gets knocked off and the geometry of the fit is broken. Then into the gapan unburned mixture gets in, which simply cokes on the valve bands, which makes the gap even larger. As a rule, such problems happen mainly with exhaust valves, since the intake valves are "grinded" by incoming flows. In addition, there are no obstructions to the air flow, and at the moment when the temperature is at its highest, the valves are closed.

Now directly about how the valves are lapped. VAZ categorically prohibits the owners of these cars from grinding with a drill. According to them, it is impossible to make the necessary effort. But the fact is that the effort is just not required. If you apply it, then the saddle will grind unevenly. In this case, the valve will not be accurately centered, resulting in a gap on one side. This is fraught with the consequences described above. Yet lapping the valves with a drill may not be as effective as it can be with a special set.

It is produced in three stages. Their sequence depends on the grit size of the lapping paste, which changes in the process. If the valves are lapped with a drill, then a pin of the same diameter as the rod is clamped into it. One end of the hose is put on this pin, and the other on the valve. Then the saddle and girdle are lubricated with paste, after which small rotational speeds are set. If they are too small, then this is not a problem - the operating time will increase slightly.

If they are large, then there is a risk of overheating andseats, and valves. Then a characteristic blue stripe will appear on them. This is a sure sign of overheating. After the initial processing, the paste is erased, then the next, smaller grain size is rubbed. After applying the third paste, the surfaces are thoroughly wiped with kerosene. Then you need to lubricate them with engine oil and repeat the lapping procedure, observing the “high-speed mode”. This will ensure that the closure is as tight as possible.

Well, after that, the compression in the cylinders will noticeably increase. It should be remembered that engines with a compression ratio of less than 8 are very sensitive to it. This greatly affects the ease of operation, so the valves can be lapped even between repairs, for example, after 20,000 km of run.

Recommended:

Adjustment of engine valves 4216 "Gazelle": procedure, work technique, necessary tools and expert advice

Car enthusiasts can do without the services of specialized car repair shops if it is necessary to adjust the valves of the 4216 Gazelle engine. Consider how this is done with your own hands in a garage environment

Valve clearance: what should it be? Instructions for the correct adjustment of valves VAZ and foreign cars

The car engine is equipped with two or more valves per cylinder. One is designed to let the fuel mixture into the cylinder. The other is used to release exhaust gases. In technical terms, they are called "inlet and outlet valves". The gas distribution mechanism of the engine sets the sequence of their opening at a certain moment of the valve timing

Reducing valves: device and principle of operation

Reducing valves are mechanisms that are designed to maintain low pressure in the discharged fluid stream. Most often, such tools are used in hydraulic drives, in which several devices are powered from one pump at once. In this case, pressure reducing valves normalize the pressure under which liquid is supplied to all consumers, that is, an excessively increased or, conversely, reduced pressure does not occur in the system

How to properly adjust the valves on the car?

Every car needs periodic valve adjustment. If this is not done on time, the car will begin to lose its traction, the drive will begin to make noise and the load on the rest of the internal combustion engine will increase. To prevent this from happening, it is necessary to adjust the valves in a timely manner. Learn how to do this in today's article

Troit the Priora engine (16 valves): causes and troubleshooting. How to check the spark plugs and ignition coil "Lada Priora"

Despite the huge amount of criticism against the Lada Priora, this is one of the most popular cars that have come off the AvtoVAZ assembly line in recent years. "Priora" is equipped with a fairly successful engine with good dynamics, the interior turned out to be very comfortable. And in the maximum trim levels useful options are offered. But at the same time, from time to time, the car brings minor problems to the owners. One of the most popular malfunctions is the Priora engine troit (16 valves)