2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:18

It's no secret that proper and regular maintenance of bearings provides a significant extension of the service life of this element, which is an integral part of the entire automotive mechanism. Let us further consider the features of the products used as lubricants for bearings, as well as their varieties and correct use.

What is lube for?

The main purpose of high-speed bearing greases is that these products prevent excessive friction, as well as overheating of the part in question. As a result of providing such protection, the moment of wear of parts, as a result of which they fail, is significantly removed.

The product in question can be used in relation to high-speed friction and rolling bearings, as well as those that guide various mechanisms.

Making a general characterization of lubricants forhigh-speed bearings, it should be noted that all products from this series have the optimum viscosity of the base fluid (150 cSt or 220 cSt). The principle of its action is based on the fact that with an increase in the speed of rotation of the bearing itself, this indicator begins to decrease, as a result of which the liquid becomes less viscous. The result of all this is to prevent significant overheating of the entire mechanism and its possible failure.

During their action, lubricants perform a number of functions:

- prevent dust and debris from outside;

- protect metal from corrosion;

- contribute to the even distribution of temperature generated during friction;

- cooling while observing elevated temperature.

When using lubricants for high-speed bearings, the friction of the parts among themselves is significantly reduced, which ensures a longer use of the part. It also helps to prevent the formation of an unpleasant sound that can be observed while driving.

Key Features

There is a certain list of characteristics that all those who seek the right grease for high-speed bearings should definitely pay attention to. These include:

- channeling;

- viscosity index;

- presence of additional components (additives);

- dropping point.

As for the viscosity of the product, it should allow it to form a kind of filmon the surface of the bearing. This layer must be thick enough to prevent excessive friction.

As for channeling, this indicator indicates the ability of the agent to prevent overheating of the device. In a quality product, it should also be high.

Speaking of the dropping point, in a suitable product this indicator should be higher than that indicated as the maximum working for a particular device (you can find it in the instructions).

A high-quality grease for high-speed bearings must necessarily contain substances that prevent the formation of corrosion. What's more, anti-wear and EP additives can be added to a good product.

Features of operation under different temperature conditions

Any motorist who wants to take care of the condition of his car should pay attention to the fact that temperature conditions can affect the properties of grease for high-speed rolling bearings. So, if the product is designed for use at high temperatures (this should be indicated on the product packaging), then it should be understood that when the temperature drops, the composition will begin to crystallize and harden. If it is intended for use in frosty conditions, then with the onset of heat, the mass will begin to coke or dry out altogether.

It should also be understood that the basis on which the product is made is of great importance. So if hebelongs to the mineral category, it should be understood that this composition is able to maintain its normal state at temperatures from -30 to +120 degrees. Silicone lubricants are great for use in frosts - from -30 to -70 degrees, and for engine treatment it is best to use pasty compounds that can maintain their properties at temperatures from +200 to +1000 degrees.

Types of lubricants

Currently, modern manufacturers of products intended for servicing machines and individual parts offer a large selection of lubricants that differ from each other in their form. To date, in stores you can find lubricants presented in the form:

- butter;

- ointments;

- solid material;

- gas.

Speaking about the features of each of the presented types, it should be noted that gaseous lubricants are ideally combined with bearings used in turbochargers, ultracentrifuges, friction units of precision instruments, as well as in gas turbines. For the care of automotive parts, such products are almost never used.

For hard materials, plain bearings are the ideal application. The advantage of such a tool is that they form a very dense layer, due to which the level of friction and the likelihood of early wear of the product are reduced.

Most often, lubricants are used to care for bearings, presented in the form of oil and ointment. They are universal and suitable for the types of parts under consideration. As for oilformulations, they provide maximum bearing protection against friction, clogging and overheating.

Features of the composition of lubricants

It should be noted that the formulations of different bearing greases vary. So, in fact, you can find pigment, soap and lithium products. Consider further the distinctive features of each of them.

Soap lubricants are based on sodium and calcium. They are low cost and thermally stable.

Speaking of lithium compositions, it should be noted that they are based on an oil residual base, freed from paraffins. These lubricants are also relatively inexpensive and have water-repellent properties, as well as a high adhesion rate.

As for the pigment compositions of lubricants, their main feature is that each product of this type has a certain color, acquired due to the presence in the structure of the product of a special component that determines some of its properties. Such compounds also perfectly repel moisture and have a high level of adhesion.

Which grease is suitable for wheel bearings?

Speaking of the fact that manufacturers of automotive maintenance products and individual parts currently offer a large selection of bearing lubricants, it is worth noting that choosing the most suitable product is based on the main purpose of its use.

So, when choosing a lubricant for hub bearings, preference should be given to those compounds thatwhich provide protection against corrosion and dirt ingress. It is also very important that such a product has the property of sealing, and is resistant to high temperature conditions.

Specialists note that the following products will be excellent options for lubricants for wheel bearings:

- Liqui Moly LM 50;

- Castrol LMX Li-Complexfett;

- MS-1000;

- Step Up HIGH TEMPERATURE;

- "Litol 24".

How to choose a lubricant for rolling bearings?

When choosing the most suitable grease for high speed rolling bearings, you need to pay attention to the basic conditions of use of the unit. Experts note that lubricants in the form of oils are excellent for bearings of this type - they do an excellent job of removing temperature, and also have excellent penetrating power.

More often than not, car service technicians recommend using Mannol brand products for this purpose, which significantly reduce costs and are also distinguished by their durability. Also, synthetic-based lubricants - barium - are excellent for use. It is often noted that an excellent option for high-speed rolling bearings is Indigo grease. This product has a very thick consistency and belongs to the group of ceramic modified.

How to choose a bearing grease for an electric motor?

Speaking of lubricant selection forof the type of bearings in question, it should be noted that in this case it is worth paying attention to those products whose main functions are to prevent dirt and dust from settling inside the mechanism. In terms of form, an excellent lubricant option for high speed motor bearings is one that comes in the form of oil.

Top products in this category include:

- SKF LGHP 2;

- SKF LGWA 2;

- SKF LGHB 2;

- Molykote FB;

- BLUE (MC-1510);

- MOBIL XHP;

- SHELL Gadus;

- VNII NP-233;

- "Tsiatim-221".

Practice shows that in the bearings of electric motors, the lubricant is replaced most often - once every three weeks, subject to daily use of the device.

Top Producers

Based on the feedback left by consumers, a rating of the best manufacturers of lubricants for high-speed vehicle bearings was formed. These include:

- LIQUI MOLY (Germany);

- "VPMAvto" (Russia);

- Mannol (Germany);

- HUSQVARNA (Sweden);

- CHAMPION (Russia).

Redline CV-2 High Speed Bearing Lubricant receives a huge amount of positive feedback. The peculiarity of this product is that it is able to adapt even to the lowest and highest temperature conditions (from -70 to 260 degrees) and to extreme loads. It is characterized by high corrosion resistance, as well as the ability toprolong bearing life. All this is provided thanks to the red molybdenum component, which is part of the product, which is much more effective than the black one, which is part of other similar products.

When is it time to change the lubricant?

Automotive service professionals often note a number of signs that indicate that it is time to replace the grease in the bearing. These include:

- producing a sound or smell that is uncharacteristic of the device operating in normal mode;

- appearance of chips or cracks on the top of the friction unit;

- change in the consistency or color of the visible part of the grease;

- heating equipment to excessively high temperatures.

It should be noted that when such "symptoms" are observed, the lubricant must be changed immediately, since ignoring the listed phenomena can provoke irreversible consequences that will negatively affect the operation of the entire device.

How to use lubricant?

How to properly use the product in question? First of all, you need to understand that you need to put grease for high-speed bearings with your own hands, on which you must first put on gloves. This moment is very important, since this is the only way to ensure the closest contact of the agent with the element being processed.

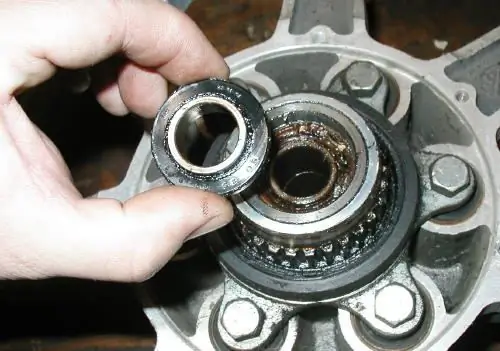

At the very beginning of the eventprocedure, it is necessary to open the bearing with a sharp object, and then lower the part into a container with gasoline in order to thoroughly rinse it and, thereby, clean it of the old mass with which it was processed.

After washing, the part must be dried and only now put new grease into it so that it occupies about a third of the total volume of the hole allotted for its bookmark.

At the final stage, the spindle treated with high-speed bearing grease must be tightly closed and the part installed in its place.

Price

Speaking of the cost of the best greases for high speed bearings, it should be noted that it directly depends on several factors. These include the level of quality of the raw materials used to create the product, as well as the use of special modifiers (additives). Moreover, the price of the finished product is affected by the technology used in its production, as well as the volume of the bottle in which the product is sold.

Practice shows that the average cost of high-quality grease for bearings varies between 450-900 rubles.

Recommended:

Liqui Moly 5W30 oil: composition, varieties and characteristics

Liqui Moly 5W30 is a multi-purpose engine lubricant that provides an unprecedented level of engine protection. The original Liqui Moly 5W30 oil is manufactured using proprietary technology. The product is produced by the German company of the same name, which has received many awards in the field of lubricants

What kind of oil to fill in the Niva-Chevrolet: types, characteristics, composition of oils and their effect on the operation of a car

The article provides detailed information about the oil that is best filled in the Chevrolet Niva. These are popular manufacturers, varieties and features of oils, as well as detailed instructions for replacing old oil with a new one

LIQUI MOLY grease: manufacturer, dosage, characteristics, composition, features of use and reviews of motorists

High-performance operation of expensive modern equipment is ensured by special lubricants. The impossibility of using conventional oils in mechanisms causes the need for greases. Liqui Moly products provide efficient and long-term operation of the main mechanisms, protecting them from wear and friction

Carboxylate antifreeze: manufacturer, dosage, characteristics, composition, features of use and reviews of motorists

Coolants are produced by many manufacturers. To understand this abundance, to choose the right antifreeze that will not harm the engine and will not cause serious damage, this article will help

Additive RiMET: description, composition and reviews of motorists

RiMET additives are a group of unique products, the main action of which is aimed at improving the basic characteristics of the car. Let us further consider the main features of the brand's advanced products, as well as their direct purpose