2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:11

Pumping equipment performs its functions normally only if there is a medium in the pipes and pump. The pumped medium is both a lubricant and a coolant for the equipment itself. If this substance disappears and the pumping equipment starts to idle, it will soon fail. To avoid such situations, dry running sensors are used for the pump. If the pumped medium fails, a sensor or relay turns off the power to the pump, preventing it from breaking.

Dry running

The very phenomenon of dry running can cause equipment failure, if the pump breaks down due to such a phenomenon, warranty repairs may not be achieved.

Dry running may be caused by conditions such as:

- incorrect selection of the pump installation height, this can lead to the fact that during operation the water column during pumping will gradually decrease and the pump will begin to entrain air;

- whenlong-term use of a well without cleaning it can silt up, because of this, the water level will be replenished for a longer period of time;

- if the pump is installed on the surface of the liquid, during operation, wear of the nozzles may occur and air will pass through them.

If you do not pay attention to these conditions and do not use a dry running sensor for the pump, the latter may overheat and the motor winding may burn out.

Level sensor

One of the varieties of the dry run sensor is a water level switch to control the liquid column itself. The float switch uses a floating contact block, when it is at the maximum level, the contacts are normally closed, if the level drops and the float drops to the minimum level, they open and turn off the power to the electric motor.

The water level control sensor in its design has a group of floats. One of them is located at the minimum allowable level, and the other is set a little lower, the minimum current flows between them. If the level of the water column falls below the minimum value, the current flow between the floats stops, the pump is turned off.

This type of dry-running sensor is good in that it prevents the pump from trapping air when the water column drops, thereby eliminating the possibility of motor failure.

Protection relay

The electromagnetic pressure switch is another type of dry water sensor. During the pressure drop of the fluid flow insystem, it shuts off the pump motor. The design of the relay uses a membrane and a contact group.

During operation, the pumped medium presses on the membrane, while the contacts are closed. If the pressure drops, the diaphragm drops, opening the group of contacts, the power is interrupted.

The pressure drop in the pipeline can be due to several reasons:

- failure of the pump pump itself;

- each pumping equipment uses a filter, clogging of this element can cause a drop in water flow pressure;

- It could also be that the pump is above water level.

You can mount such a sensor both on the pump itself and separately, it is also possible to use it in combination with a water pressure switch.

Pressure sensor

The water passage control relay is also a kind of dry water running sensor. It is an electromechanical device.

In the design of turbine relays there is a rotor in the form of a turbine, on which an electromagnet is located, a magnetic field is induced during the passage of the fluid flow, special controllers read the generated pulses. If the flux decreases, the magnetic field weakens accordingly and the controllers turn off the power.

The paddle relay has a light plate, which, when the flow passes, is deflected and closes the contacts; if the flow drops, the contacts open and the power is turned off. This type of dry running sensor is distinguished by itssimplicity and low cost.

Special sensors such as flow controllers monitor several parameters. They control the water pressure, the flow of the pumped medium, and turn off and on the contacts of the pump motor. In some cases, they are equipped with check valves. In this regard, connecting a dry-running sensor of this type is expensive.

Features of choosing a sensor

When choosing a dry running sensor, you should focus on some conditions:

- depth of immersion of the pipeline, the height of the level of the pumped liquid;

- diameter of the well itself;

- choose which pump will be needed - submersible or surface;

- financial opportunities.

Float sensors are used for a well, a water level sensor is suitable for wells with a clean pumped medium, and a flow or medium pressure switch is used for a dirty medium.

The use of a dry-running sensor is mandatory, its use can keep the pumping equipment in working order. In some cases, if it is possible to turn off the pump in a timely manner and visually control the water level, such relays can be omitted.

Recommended:

What is FLS: decoding, purpose, types, principle of operation, characteristics and application

This article is for those who don't know what FLS is. FLS - fuel level sensor - is installed in the fuel tank of a car to determine the amount of fuel inside the tank and how many kilometers it will last. How does the sensor work?

Types of car tinting. Car window tinting: types. Toning: types of films

Everyone knows that different types of tinting make the car more modern and stylish. In particular, dimming the windows in a car is the most popular and popular way of external tuning. The whole advantage of such modernization lies in its simplicity and relatively low cost of the procedure

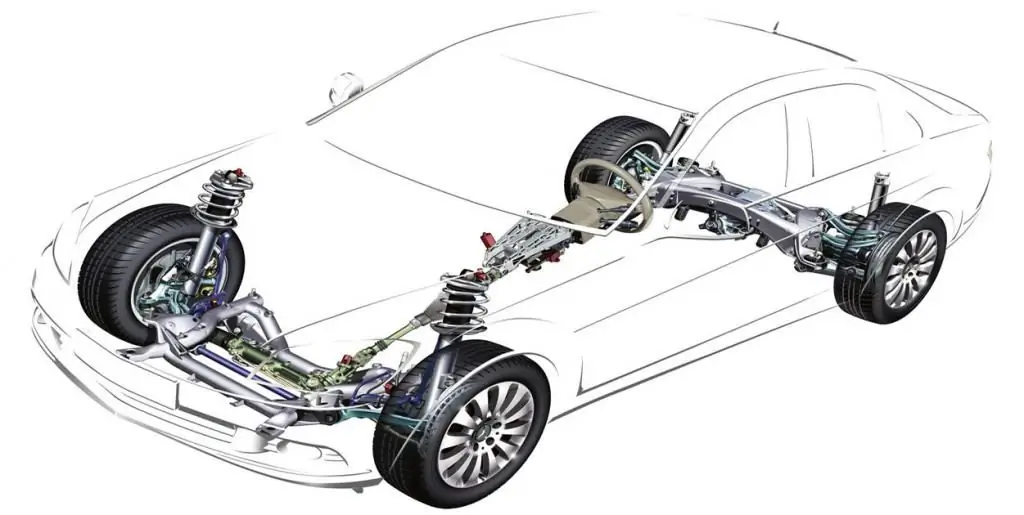

Types of car suspensions: device and diagnostics, features and benefits of various types, reviews

Are many drivers interested in the types of car suspensions? But to know the device of your vehicle, in particular, what parts its chassis consists of, is desirable for certain reasons. This is not only an additional experience, but if necessary, you can take appropriate measures

Car operation is Types, characteristics, categories, depreciation and fuel consumption calculations, features of work and technical use

Logistics of road transport is an important factor in technical operation systems and is a process of supplying automobile enterprises with rolling stock, units, spare parts, tires, batteries and materials necessary for their normal operation. Proper organization of logistics plays a crucial role in improving the use of vehicles by keeping them in good condition

Dry sump: principle of operation, device, advantages and disadvantages

What features does a dry sump have and why is it better than a wet sump? Everything you need to know about the ICE lubrication system: device, principle of operation, main characteristics, details, advantages and disadvantages