2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:16

One of the most popular devices for automatic connection and disconnection of railway train cars is the SA-3 automatic coupler. It is a device that provides coupling and disconnection of wagons and locomotive. Thanks to its design, the SA-3 automatic coupler keeps the cars at the right interval, connects and disconnects them, and makes their contact possible without harming the car frame and the automatic coupler mechanism itself.

Purpose of mechanism

To modern devices necessary for automatic uncoupling and coupling of cars, include SA-3, despite the fact that it was developed back in 1932. The device is quite popular now. The secret of success is a good design, simple and effective, as well as reliability and ease of use and maintenance.

The modern fleet of railway vehicles useswagons of various designs and purposes. There are cargo and passenger. There are also conditions for their use. A number of wagons and locomotives are operated in rather harsh conditions: increased intensity of use, excessively high or low temperatures, transportation of people and goods over short distances.

With a small mileage, the power of the device increases when performing loading and unloading manipulations, and, as a result, the question of using a device that allows automatic coupling and disengagement of train elements becomes relevant. It is to these devices that this device can be attributed, since the purpose, characteristics and design of the SA-3 automatic coupler are fully suitable for these purposes.

Shock-traction device - automatic coupler SA-3 allows you to carry out:

- Automatic connections of wagons when they collide and block the lock of coupled automatic couplers.

- Automatic uncoupling of rolling stock wagons, which are carried out without the intervention of a specialist, and keeping the device in the disengaged position until the automatic couplers are opened.

- Automatic return of the fixture parts to their initial position, allowing them to be coupled and block the lock when hitting the wagons.

In addition, the SA-3 automatic coupler mechanism allows you to re-couple randomly uncoupled couplers without separating train cars. Maneuvering work, i.e.their conduct, the impact of automatic couplers does not lead to their association. Until the moment of adhesion, the parts of SA-3 take the following mutual positions:

- axes of devices are placed on one straight line;

- axes are offset vertically or horizontally.

In this case, vertical axial displacement can be allowed in a freight train. Axle displacement occurs up to 100 millimeters, and also in a high-speed passenger train up to 50 millimeters. The maximum value of the horizontal axial displacement does not exceed 175 mm. With these displacements of the axles, the operation of the SA-3 automatic coupler consists in high-quality and safe automatic coupling of cars during their operation.

Design of automatic coupler model SA-3

The CA-3 coupler can be divided into several components to ensure smooth operation:

- Case, spare parts and parts of the working mechanism.

- Impact-centering device.

- Draft device.

- Stops.

- Drive for uncoupling cars.

Effective operation of the SA-3 automatic coupler is achieved through the interaction of all parts of the mechanism and the molded hollow space in the body. In its main part are the details of the mechanism (they are placed in a cavity called a pocket):

- castle;

- lock holder;

- lift roller;

- key lift;

- fuse to protect against arbitrary self-uncoupling of automatic couplers;

- bolt.

In addition to the head part of the bodyequipped with an elongated tail. It also has a hole for the blade, which connects the traction collar and the SA-3 automatic coupler. In the connected position, the mechanisms that are located on adjacent cars are in contact with each other by means of protruding from the throat (this is the segment between the large and small teeth), lock holders and locks.

In this regard, we can conclude that the condition of the CA-3 automatic coupler devices determines the stable and uninterrupted operation of the entire device as a whole.

Dimensions and weight of automatic coupler SA-3

Auto coupler has the following parameters:

- Dimensions of the SA-3 automatic coupler: 1130 x 421 x 440 millimeters.

- The weight of the SA-3 automatic coupler can vary from 207, 18 to 215 kilograms. It depends on the blueprint of the device.

The dimensions of the automatic coupler make it a fairly versatile device that is equally well suited for both freight and passenger trains.

Upgraded SA-3 coupler

In the 2000s of the twenty-first century, the modernized SA-3 automatic hitch began to be used in Russia. The device and operation of the SA-3 automatic coupler remained unchanged, but the design was improved. The device received two brackets that prevent parts of a broken hitch from falling onto the rails. The fall of the parts leads to damage to the arrow or to the collapse of the train.

Thus, along with the upgrade, the security level of the new device model also increases. But that's not allbrought innovation. The distance of the repair-free run of the new model of the device was 1,000,000 kilometers. The old SA-3 automatic coupler, in terms of purpose and characteristics, boasts only 200,000 kilometers. Given that the safety and savings on device repairs have increased, older models began to be taken out of service very quickly. However, the purpose and design of the SA-3 automatic coupler in its original version have firmly entered the history of the Soviet and Russian railways.

SA-3 coupler failures

Autocoupler SA-3 with a certain number of problems is not able to fully perform its functions:

- Fracture of the mechanism components, as well as a microcrack in the instrument case.

- Contouring of working surfaces, broken fuses, expansion of the throat.

- A roller that was not fixed from falling out, a roller fixed incorrectly or abnormally, as well as its absence.

- Breakage of the wedge or roller of the traction clamp. Crack in the wedge, roller and traction collar.

- Crack and (or) breakage of the centering beam, pendulum suspension. Incorrectly installed pendulum hangers.

- Atypical roll of wedge or roll, traction collar component failure.

- Breakage of the strap or the formation of a crack in it.

The purpose of the bar is to support the traction yoke, bracket, as well as the drive holder for the release, the socket for impact and the thrust plate, or the stops themselves. A bent release lever is also a major problem with the CA-3 coupler.

The above faults are the main ones. With the presence of these faults, the automatic coupler is unsuitable for operation, since its stable operation will be in big question. To eliminate a number of malfunctions, parts are sent for repair. Those parts in which the working surfaces are worn out cannot be repaired and are replaced with new ones.

This may cause backlash and deviations from the norm. Their appearance threatens insufficiently strong adhesion and, as a result, uncoupling while the train is moving. In the event of backlash and deviations above the norm, the automatic hitch is immediately repaired. Since non-compliance with the established operating rules endangers the lives of train passengers.

Comparative characteristics of automatic couplers SA-3 and CAKv

The seventies of the twentieth century were marked by the fact that the development of a new automatic coupler standard intended for the EU railway traffic began. One of the developments - CAKv has become quite widely used not only in European, but also in Russian trains.

CAKv based on SA-3 and fully compatible with Soviet design. However, there are differences; in the German version, an additional protrusion is equipped on the large tooth, which falls into a special groove. This changes the hitch from soft to stiff.

A rigid hitch can be used to connect electrical connectors and brake lines. CAKv is used to connect wagons, large freight trains. itdue to the fact that the screw harness used on the SA-3 is not able to withstand the load of the freight train.

Countries where CA-3 coupler is used

Despite its “venerable” age, many people are satisfied with the device and operation of the SA-3 automatic coupler, it is still popular in many countries of the world. For example, it is used in some Arab countries such as Iran and Iraq. Also, the SA-3 automatic coupler can be found on the railways of Mongolia, Kazakhstan, Uzbekistan, Belarus, Latvia, Lithuania, Georgia, Estonia, Ukraine, Tajikistan, Moldova, Azerbaijan, Finland, Sweden and Russia.

At the same time, the Russian version is equipped with additional brackets that prevent the uncoupled parts of the automatic coupler from getting on the railway tracks. Thanks to the use of protective equipment, the number of accidents and train accidents caused by a broken part of an automatic coupler that fell under the wheels of a train has been significantly reduced.

Deciphering the abbreviation SA-3

The abbreviation SA-3 is translated as Soviet automatic coupler, 3rd version. It is worth noting that after its creation, in 1935, the transfer of the entire railway transport of the USSR to devices of a new type started. The transition was completed in 1957.

It is worth noting that at that time a transitional device was used in the form of a two-link chain. The device was a metal corner to which two pieces of chain were welded. The corner was mounted in the mouth of the SA-3, but the chain was thrown onto the hook,welded to the screw hitch. Thanks to this element, it was possible to connect cars with an old coupling device and equipped with an SA-3 automatic coupler.

The creation of the SA-3 made life much easier for the coupler. The purpose and design of the SA-3 automatic coupler made it possible to reduce his duties to the combination of sleeves that provide braking and electrical cables.

Curious facts

The CA-3 automatic coupler has a rather popular design, which throughout its existence has established itself as a reliable and durable element that allows you to automatically connect and disconnect cars.

The purpose of the SA-3 automatic coupler is to connect and disconnect the elements of the rolling stock, but its characteristics allow the coupler only to ensure that the coupling and uncoupling process goes as it should. During the entire existence of the automatic coupler, a number of interesting facts about this element have accumulated:

- CA-3 was developed in 1932 in the USSR. Soviet designers took as a basis an automatic coupling made in the USA (Willison automatic coupler), developed in 1910, and practically re-created the domestic version. The engagement contour has also been redesigned. In the West, SA-3 is referred to as a "Russian coupler" or "Willison coupler with a Russian contour."

- If the automatic coupler CA-3 is disconnected incorrectly, it is necessary to press a steel rod into a certain hole, which is located in its body. The components of the mechanism will return to their original position, and the automatic coupler will be coupled.

- The coupler is equipped with a signal arm. Heis a protrusion that can be seen at the bottom of the fixture, provided that the lock is not locked. When a specialized train maintenance worker inspects each automatic coupler, notices the offshoot, he will know that the cars are uncoupled from each other.

- As you know, the automatic coupler is equipped with a draft gear, a device that absorbs the impact momentum and protects the wagon frame and components of the automatic coupler mechanism from destruction. However, the SA-3 locomotive and engine automatic couplers are not equipped with this device. The thing is that on the locomotive and motor frame there is simply no place to install this element.

- The Polish version of the name of the SA-3 automatic coupler is Brezhnev's fist.

- In 1898, the question was raised about the commissioning of automatic couplers for Russian railways. One option was Janney's American coupler. But the idea had to be abandoned. Due to the unreliability of the design of the American version, as well as the inability to choose a suitable option from existing domestic automatic couplers, the introduction of a device for automatically coupling and uncoupling cars was postponed indefinitely.

- Soviet coupler (3rd option) is used not only in the post-Soviet countries, but also in some European countries, such as Poland, Finland, Norway and Sweden. Also, based on the SA-3, a European version of the CAKv was developed, which, with a slight modification, completely repeats the design of the domestic automatic coupler. Only unlike the domestic one, the foreign one makes it possible to implement a toughcoupler, which is necessary to connect the wagons of a freight train.

- The average cost of a new SA-3 is 10,500 rubles. Repair of the same units of the device varies in the range from 300 to 1000 rubles. Therefore, timely repair of the coupler allows you to save a fairly large amount of money.

Conclusion

Summing up the above, it is worth noting that the SA-3 automatic coupler is a fairly reliable and durable device that allows automatic uncoupling and coupling of wagons. At the same time, increased requirements are imposed on the condition of the device: there should be no worn parts, broken components of the mechanism and cracks in the body and parts of the mechanism. In the event of a malfunction, the SA-3 is sent for repair. If the device is worn out, then it is replaced with a new one.

The SA-3 automatic coupler was developed back in 1932 on the basis of the American automatic Willison coupler. At the same time, Soviet designers independently thought out the design of the coupling circuit, for which the SA-3 coupling received the name "Russian automatic coupler".

The transition to automatic coupling began in 1935. At that time, a transitional device was used, which made it possible to connect cars equipped with couplers of a new and old model. The transition finally ended in 1957. At the beginning of the 2000s, the SA-3 was slightly modified. Special brackets appeared in the design of the coupler, which made it possible to protect the railway track from falling on it of parts broken off from the coupler. Canvas protection, in itsturn, prevents the failure of the switch, and also reduces the likelihood of an emergency leading to a full-fledged railway accident. Modernized couplers are used in trains carrying oil products, as well as in passenger trains.

SA-3 automatic hitch is well known in Europe. Largely due to its reliability and durability. At the same time, as we have already noted, many samples of foreign devices of a similar plan were created on the basis of the Soviet automatic coupling.

Thus, the conclusion suggests itself that the SA-3, created back in 1932, can more than function for about ten or twenty years, or even much more. After all, the reliability of a structure is measured not only by its characteristics, but also by its impeccable reputation and years of constant automatic coupling and decoupling of trains.

But despite the high popularity, the CA-4 came to replace the CA-3 - it has a more modern and reliable design. In addition, compared to the third SA-4, it has an increased resource of maintenance-free mileage (200 thousand kilometers of the third versus 1,000,000 kilometers of the SA-4).

Also, the fourth one is much lighter and more efficient than its predecessor. Despite the advent of a more advanced hitch, the CA-3 is still quite common, largely due to its lower cost compared to the CA-4. SA-3 continues to be one of the most popular automatic couplers.

Recommended:

Knuckle "UAZ Patriot": device, characteristics and purpose

Replacing the steering knuckle on the UAZ "Patriot". The device of the steering knuckle on the car UAZ "Patriot". How to remove the steering knuckle on the UAZ "Patriot". Scheme and principle of operation of the steering knuckle on the UAZ "Patriot". How to replace the steering knuckle on a UAZ Patriot car

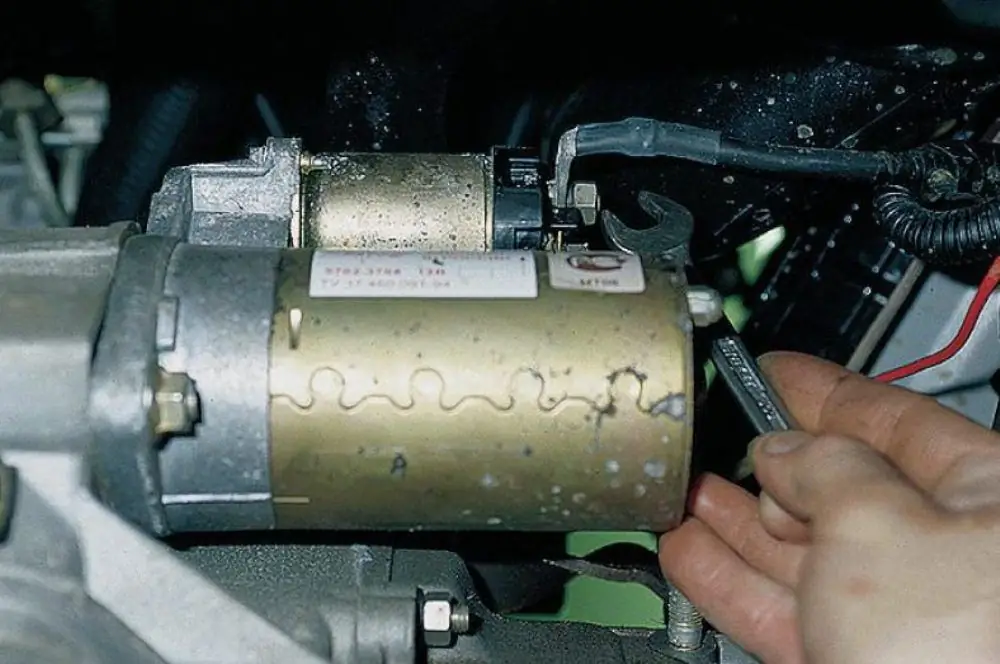

Where is the VAZ-2112 starter relay located? Location, purpose, replacement and device

The starter relay on the VAZ-2112 performs an important function on any car, regardless of model. Failure of this device leads to the fact that the car will not start. Drivers who are engaged in self-repair of the vehicle need to know where this unit is located and how to fix it if any malfunction occurs

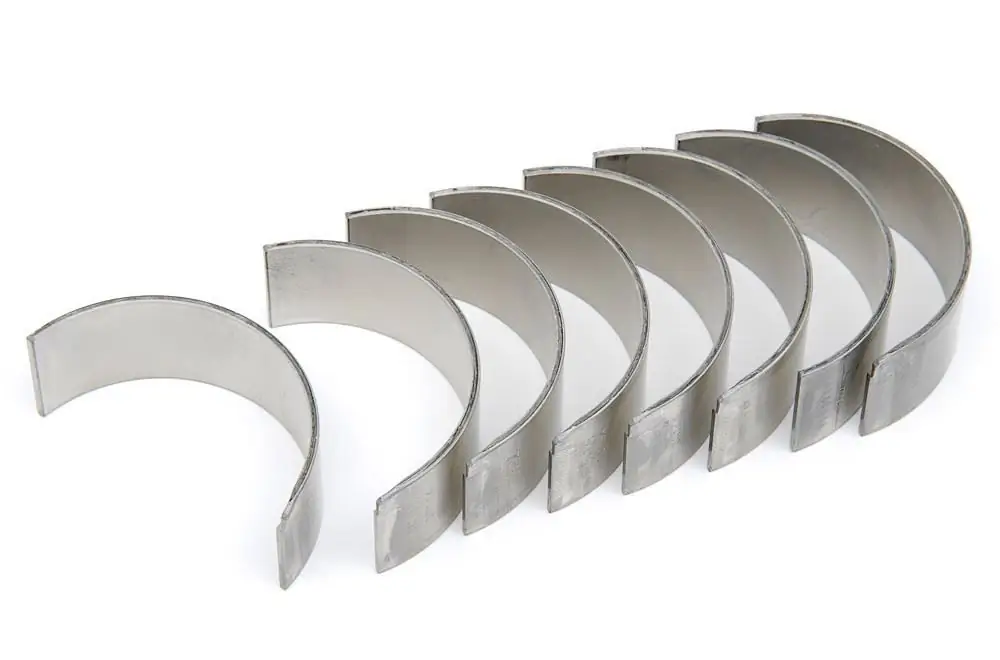

Connecting rod bearing: device, purpose, specifications, features of operation and repair

The internal combustion engine works by rotating the crankshaft. It rotates under the influence of connecting rods, which transmit forces to the crankshaft from the translational movements of the pistons in the cylinders. In order for the connecting rods to work in tandem with the crankshaft, a connecting rod bearing is used. This is a sliding bearing in the form of two half rings. It provides the possibility of rotation of the crankshaft and long engine operation. Let's take a closer look at this detail

Ball pin: purpose, description with photo, specifications, dimensions, possible malfunctions, dismantling and installation rules

When it comes to the ball pin, it means the ball joint of the suspension of the car. However, this is not the only place where this technical solution is applied. Similar devices can be found in the steering, in the guides of the hoods of cars. They all work on the same principle, so the diagnostic and repair methods are the same

Engine pistons: device, purpose, dimensions

Despite the growing popularity of electric vehicles, the internal combustion engine is still the main type of car engine. This unit has the abbreviation ICE, and is a heat engine that converts the energy of fuel combustion into mechanical work. The main component of the internal combustion engine is the crank mechanism. It includes the crankshaft, liners, connecting rods, and pistons. We'll talk about the latter today