2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:16

Nozzles are designed to spray fuel mixed with air entering the cylinders of an internal combustion engine under high pressure. If the nozzle is serviceable and clean, then the sprayed mixture enters the cylinder in a cone-shaped form. If it is clogged and has carbon deposits, then the spray pattern and the proportion of the fuel-air mixture will change, which will increase fuel consumption and adversely affect engine performance. To prevent this from happening, the owner of the car should not lose sight of their condition, and regular flushing of the nozzles should be a must.

Fuel injectors operate in a very aggressive environment. In this regard, the quality and purity of the fuel are of great importance, since very small organic contaminants, burning, settle on the nozzles of the nozzles in the form of a layer of soot. Flushing nozzles is needed in order to clean this soot. It can be done in many ways.

More recently, do-it-yourself washing of injectors was not so much a priority as the only opportunity for all motor vehicle drivers without exception. Today, special technologies have been developed,which make it possible to carry out preliminary prevention of the formation of carbon deposits on nozzles and specialized equipment, which is commonly called stands, where automated washing of nozzles is performed.

Vehicle owners wash their own vehicles with additives (additives) to the fuel. Nowadays, the market offers a wide range of equipment care products, including reagents, with the help of which the nozzles are pre-washed. They need to be added to the fuel system every two to three thousand kilometers. As a result, the slight soot that forms on the nozzles during the operation of the car is removed.

These additives are good and effective, they extend the life of the injectors, help keep the entire fuel system clean, but only as a prophylactic that prevents the formation of a thick layer of carbon deposits. In no case should additives be added if there are already old dirt on the nozzles. Pieces of soot washed off the surface of the nozzle will penetrate the filter, clog the pipeline, get under the high pressure of the fuel pump into the cavity of the nozzles and completely ruin them.

Therefore, when there is already a layer of soot on the nozzles of the nozzles, it is possible, without removing the nozzles from the engine, to wash them with solvents on the stand. At the same time, the car engine starts, and at this time, the entire system is flushed, as well asthe state of the injectors, their performance and the form of spraying the fuel mixture are tested. Such in-line flushing of nozzles in an automated mode does not take much time. It is effective at the stage of medium pollution, so it is recommended to use it regularly.

If the nozzles are already coked, then only ultrasonic cleaning of the nozzles will be effective for them, because the other two methods are no longer suitable, they will not correct the situation. In this case, the nozzles are dismantled and placed in a bath with a process solution through which ultrasonic radiation is passed. The coked soot begins to flake off and fall to the bottom of the tub.

Recommended:

Oil additives: reviews. All types of car oil additives

Any self-respecting motorist at least once in his life thought about the mixtures that are added to the oil to improve its properties. In order to understand what oil additives are, you first need to understand how important fuels and lubricants are for your car

Flushing hydraulic lifters: procedure. Knock of hydraulic lifters on cold

Do-it-yourself car repair in most cases allows not only to save a lot, but also to prevent serious malfunctions in a timely manner. In vehicles equipped with 16-valve cylinder heads, hydraulic lifters may knock. It is possible to correct the situation. Flushing hydraulic lifters will help. Let's see how it's done

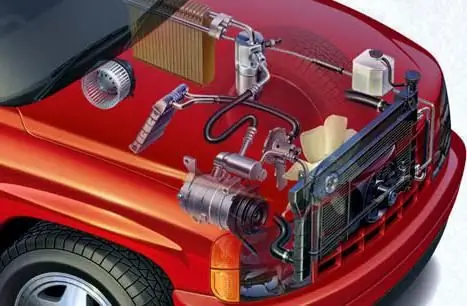

Car air conditioning system: diagnostics, repair, flushing, cleaning, system pressure. How to flush a car's air conditioning system?

The warm season is accompanied by frequent requests from car owners to service shops for such a service as diagnostics of the car's air conditioning system, as well as troubleshooting. We will understand the reasons for this phenomenon

Flushing the injector is a simple task that requires constant attention

Flushing the injector is a simple procedure that is carried out in a car service using special installations. But our domestic drivers like to take care of their cars themselves, so many of them clean the injectors with their own hands

"Hado" (additives): reviews of motorists. How to use additives "Hado"

Among the owners of various car brands, special substances called revitalizants are popular. Xado additives belonging to this category of products are in high demand. How to apply them, the advice of experienced experts will help you figure it out