2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:09

Modern cars are equipped with a vacuum brake booster, which allows you to brake smoothly and without any effort. This is especially effective on wet or icy roads. How can you understand that the Gazelle's vacuum brake booster is faulty and needs repair?

The principle of operation of the amplifier

The vacuum booster is a rounded chamber divided inside by a membrane. A discharge hose is connected on one side, and on the other side there is a valve that regulates the change in vacuum and atmospheric air. When you press the brake pedal, the discharge hose is blocked by a valve, and the membrane moves to the side, pushing the rod. The rod, in turn, presses on the piston of the cylinder. The harder we push the pedal, the more atmospheric pressure is created on the cylinder and pads.

A serviceable and good Gazelle vacuum brake booster makes the braking process more reliable. Vacuum problems will not affect the operation of the brake system completely, buta sticky brake pedal can adversely affect ride quality and lead to an accident when you need to stop urgently.

How to check

Checking and replacing the vacuum brake booster "Gazelle" is required when necessary. To do this, you do not need to lift the car every day and check it. As soon as the driver notices that it becomes difficult to press the brake pedal, the amplifier should be checked for malfunctions.

- Press the brake pedal several times until it stops and start the engine while pressed. Pressure drops in the booster will cause the brake pedal to move further forward. If you do not feel the movement of the pedal, you need to check the connection hoses for leaks. Maybe it's leaking air somewhere.

- If the above procedure does not help, then the Gazel vacuum brake booster needs to be replaced or repaired.

- We check the tightness of the amplifier itself as follows: start the engine for a few minutes and turn off the engine. Thirty seconds later, we press the brakes twice. If you do not hear the characteristic hiss of air, the part is defective.

- Purge the hose with a check valve. If air is leaking from both sides of the hose, replace the valve.

- During idle operation of the engine, "triple" begins. If at this moment you apply the brakes and the friction disappears, then the vacuum is faulty.

Sometimes it is enough to tighten the clamps more tightly to avoid depressurization, or to replace the rubber elements,such as a membrane or gasket. A preliminary check will reveal exactly what the problem is. Inspection of the part must be carried out carefully: oil leaks and even small cracks can be the cause of a malfunction. Clamps may be worn or shifted. If your attempts to repair the Gazelle vacuum brake booster have not been successful, you will have to change the mechanism.

How the mechanism works

The body has two parts: vacuum, from the side of the master cylinder, and atmospheric - from the brake pedal. A check valve is installed in the vacuum chamber, which connects the cavity with the inlet. Diesel engines have an electric pump that continuously boosts the brakes. The booster mechanism only functions when the engine is running. It also has a pushrod that, by shifting the valve, connects the diaphragm to the cylinder, and the piston pumps the brake fluid.

When you release the pedal, the return spring returns the diaphragm to its place and the braking process stops. Most modern cars are equipped with an ESR system that prevents the car from tipping over during very hard braking.

Replace part

First you will need to remove the upholstery of the engine compartment. All tubes connecting to the brake master cylinder remain in place, as long as no air enters the system.

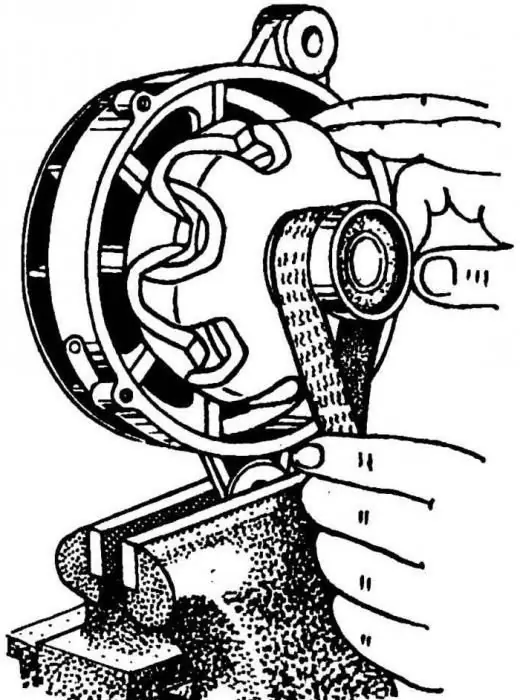

Remove the brake booster from the car in this order:

- If necessary, clean the part from dirt.

- Unscrew the nut to remove the vacuum booster from the cylinder.

- Remove the discharge hose. If necessary, you can remove it with a fitting.

- Fix the master cylinder so that brake fluid does not leak out of it.

- We twist the washers on which the amplifier rests with a screwdriver from the cabin side.

- Unscrew and pull out the bolt from the eye with key No. 17.

- Pull out two plastic spacers from the pusher hole.

- From the cab, unscrew the four nuts that connect the booster to the brake pedal, and disconnect the mechanism from the bulkhead, disconnecting the brake light wire.

- Unscrew a few more nuts from the bracket.

Unit removed. Now you can inspect the mechanism and identify a malfunction of the Gazelle vacuum brake booster. Install the new brake booster in reverse order.

Amplifier Adjustment

Before you install a new brake booster in the car, it must be adjusted. This allows the pedal to walk easily when pressed. We adjust the length of the rod, a long steel bolt that protrudes above the surface of the part. Stem length adjustment determines the pressure on the brake cylinders while pressing the pedal.

On average, this bolt should rise above the amplifier by 7 millimeters. If the distance is greater, then the pedal will have a large stroke, and if it is less, then the car will spontaneously slow down while driving. Proper adjustment of the Gazelle vacuum brake booster also affects how quickly the pedal will return to its original position. understretchedadjusting screw will bring down the effect of the mechanism.

Safety is more important

The driver must be one hundred percent sure of his car and the safety of the braking system. Now, knowing all the nuances of how the Gazelle vacuum brake booster is arranged and works, you can safely take on its repair yourself. It will be within the power of any car enthusiast.

Recommended:

Diagnosis of diesel injectors: possible malfunctions, repairs, reviews

The nozzles are subjected to the highest loads - the mechanism constantly works in aggressive environments, and the work itself is associated with high intensity. Therefore, they often fail. Diesel injector diagnostics is the first thing you need to start repairing fuel equipment and only then move on to other elements

Idle speed sensor on the VAZ-2109 (injector): where is it located, purpose, possible malfunctions and repairs

In injection cars, a power system is used that is different from the carburetor with its channel for idling the engine. To support the operation of the engine in XX mode, an idle speed sensor, the VAZ-2109 injector, is used. Experts call it differently: XX sensor or XX regulator. This device practically does not cause problems to the car owner, but sometimes it still fails

Malfunctions of the brake master cylinder, possible causes and solutions

Each car should not only accelerate well, but also slow down. This function is performed by pads, drums and many other elements. The serviceability of each of them is a guarantee of the safety of the driver and passengers. Each brake system has a master brake cylinder. Its malfunctions, design and principle of operation - later in our article

Niva Chevrolet generator: possible malfunctions and repairs

The electronics system is one of the most vulnerable parts of a car. With regular inspection of electrical components, repairs will not be required even throughout the entire operation of the car

Gazelle generator and its malfunctions. Installation of the generator on the "Gazelle". How to replace the generator with a Gazelle?

The electrical equipment of this car is made according to a single-wire scheme: the negative terminals of the instruments and equipment are connected to the "mass" - the body and other mechanisms of the car, which play the role of a second drive. The on-board network of the Gazelle is equal to the nominal voltage of 12V DC. To turn on the electrical circuit, the ignition switch is used, which consists of a contact drive and an anti-theft lock