2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:18

The electrical equipment of this car is made according to a single-wire scheme: the negative terminals of the instruments and equipment are connected to the "mass" - the body and other mechanisms of the car, which play the role of a second drive. The on-board network of the Gazelle is equal to the nominal voltage of 12V DC. To turn on the electrical circuit, an ignition switch is used, which consists of a contact drive and an anti-theft lock. At a time when the engine is not running, all electrical consumers take power from the battery, and when the engine is running, power is supplied from the alternator. While the element is working, the battery is being charged, and the onboard circuit is powered through two fuses.

The lighting circuit is equipped with a 40 A fuse, and the accessories and machinery circuit is equipped with a 60 A fuse. They are located infuse box, which is installed in the engine compartment. Also, the circuits of all consumers are protected by additional fuses with a lower current operation. They are located under the dashboard on the driver's side.

Type

The Gazelle generator is a synchronous three-phase machine with electromagnetic excitation and is designed to convert rotational motion into electrical energy. The car is equipped with models 2502.3771 or 9422.3701, the power of which is about 1000 watts. Do-it-yourself installation of the generator on the Gazelle is carried out using a mounting bracket on the right side of the power unit. It is driven by a V-belt from the crankshaft ratchet. It works in tandem with a built-in voltage regulator Ya212A11E, which keeps the voltage at the output in a given operating mode.

Possible malfunctions

If the Gazelle generator malfunctions, the operation of all electronic devices is disrupted, and the battery is not recharged. A special pointer on the dashboard informs the driver about the breakdown of this part. With such a malfunction, starting the engine and driving the car is still possible, but until the battery is completely discharged. It is impossible to drive in such a car in a normal way.

The main malfunctions of the generator include the following: violation of the integrity of the wires of the charging circuit, failure of the bearings, damage to the diode bridge, short circuit of the stator coil winding, regulator failurevoltage, slip ring wear, excessive brush wear.

The Gazelle generator, like any car mechanism, can have both mechanical and electrical damage. Therefore, both the method of repairing the breakdown and the types of operations are of a different nature.

Mechanical damage can include wear and damage to rolling bearings, springs, violation of the integrity of the housing, pulley and drive belt.

Faults, which are called electrical, include a break in the stator winding, cracks and wear of brushes, breakdown of the relay-regulator, melting of the insulating coating of the turns, interturn short circuits.

With any of these types of breakdowns, the car's generator does not fully perform its functions or completely fails, which affects the operation of all electronic devices and the engine as a whole.

Causes of malfunctions

Ordinary corrosion, wear and moisture can cause a variety of malfunctions. Mechanical failures often occur due to prolonged use of the vehicle and material fatigue, the use of poor quality materials in the manufacture of the generator, non-compliance with the operating conditions of the product and violation of the normal operating mode, under the influence of external factors such as dust, moisture, high temperature and s alt.

How to remove the generator on the Gazelle?

Now consider the issue of dismantling. Carrying out repair operations on a Gazelle car, the removal of the generator must be carried out in accordance with alltechnological instructions and comply with safety regulations during work. In the event that the car engine is hot, you must let it cool down in order to avoid the possibility of getting burned.

If there is a malfunction of the generator, it is removed from the car engine and diagnostic and repair operations are carried out. To do this, you can contact the service workshops or carry out repairs yourself. Many motorists who first encountered this problem are wondering how to change the generator to the Gazelle. The operation of removing and installing this part does not apply to complex technological and repair processes, and it can be done at home. To do this, you need a standard set of tools.

Withdrawal process

Before replacing the generator with a Gazelle, it is important to remove the negative terminal of the battery, thereby de-energizing the car's network, and also disconnect the electrical wires from the part. Next, you need to loosen the belt tension using a special mechanism and remove it. Then, having unscrewed the two fixing bolts of the generator from the engine crankcase, we remove the generator itself from the engine compartment.

If the brushes fail, it will not be difficult to replace them.

It is only necessary to unscrew the two screws securing the brushes and remove them from the body. But in case of more serious malfunctions, the element is subject to disassembly and a detailed analysis of the malfunctions.

Interchangeability

If the car can not for a long timebe under repair, the original branded generator is not available, and the faulty one needs detailed repairs, it can be replaced, thus installing the VAZ generator on the Gazelle. It is able to provide the car with the necessary amount of electricity, as it has similar performance indicators.

Dismantling

This section describes a step-by-step process that will help you properly disassemble the Gazelle generator.

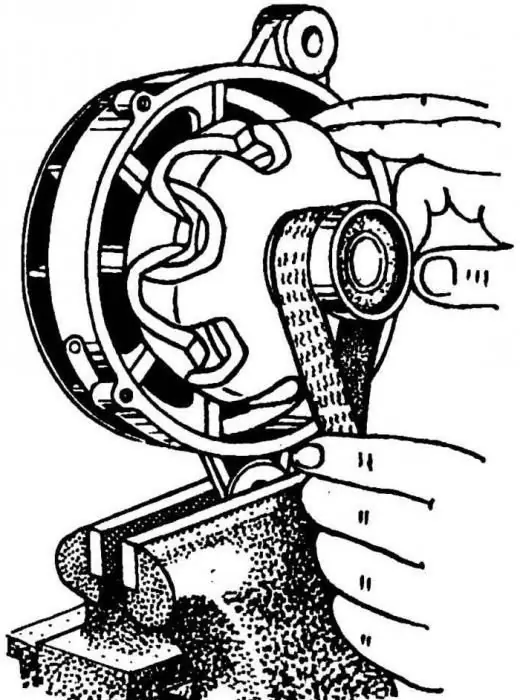

So, first you need to remove the plastic protective cover from the case. Then unscrew the brush block and voltage regulator, having previously disconnected the wiring from it. Next, unscrew the four tie rods of the generator housing and dismantle the housing cover together with the stator. Then, having disconnected the winding terminals from the diode bridge, you need to remove the stator, and, if necessary, the diode bridge itself.

Next, remove the drive pulley and the cover with the rotor bearing from the shaft.

You can carry out the process of diagnosing generator parts using measuring instruments: E236 or a special control light.

Checking the condition of parts

Regardless of which generator is installed on the Gazelle, the causes of a malfunction, as a rule, can be of the same nature.

The brushes of the generator should not have chips and cracks, when you press them with your finger, they should sink freely into the channels of the brush holder, and under the influence of the spring return to their original position.

Brush lengthshould not be less than 4 mm, and in the presence of severe wear, they are replaced with new ones.

The stator is checked for a short circuit of the coil windings to the case.

This is done by connecting one terminal of the control light to the housing, and the second is connected in turn to one of the three terminals of the turns. In this case, if there is a short circuit to the case, the control lamp will light up. Having found this type of malfunction, it is eliminated or the stator is completely replaced.

To check the stator for a short circuit between the turns, the test lamp is connected in turn to the two terminals of the windings. Moreover, if the lamp lights up, then there is no break in the turns.

The rectifier unit of the generator should be cleaned of dust and dirt deposits. Next, check the diodes using a test lamp. Due to the fact that diodes of different polarity are placed in each section, they are checked with different polarity of the battery connection. In the event that a faulty diode is found, the rectifier unit is replaced.

Checking the generator after repair

After a detailed inspection and replacement of defective elements, the generator is assembled. Assembly takes place in reverse order. After the Gazelle generator is assembled, it is important to diagnose. The good condition and correctness of its assembly can be determined by checking the speed, during which the generator gives out a current equal to 40 A and 70 A. Diagnostics are carried out on a special stand. Check motorstand smoothly changes the frequency of rotation of the rotor. At the same time, the indicators of the generator are measured, and the degree of its serviceability is determined.

Mounting the dynamo on the engine

Mounting on the engine is carried out in compliance with a certain technological process.

First, unscrew the fastening nuts of the generator brackets to the crankcase. Next, install the dynamo and fix the front mounting bolt. Then we move the front bracket and achieve alignment of the crankshaft ratchet with the drive flywheel of the part and the pump drive. By moving the bracket, we achieve the elimination of the gap between the generator loop. We install the rear mounting bolt and firmly tighten the mounting nuts of the brackets to the engine crankcase. Next, we put the drive belt on the pulleys and tighten it with the tension bracket. We carry out a control check of the tightening of all threaded connections. We connect the part to the car's electrical network and put the terminals on the battery.

Therefore, solving such a question is not difficult, and besides, the process itself takes a small amount of time. You can significantly save on the services of an auto mechanic.

Checking the alternator on the car

After installing the part in place, you need to start the car engine. Next, you need to turn on the maximum number of electrical appliances available in your vehicle (cabin heater fan, wipers, car radio, interior lighting) and turn on the headlights. At the same time, even at idle engine speed, the voltage in the onboardthe network should be 13.8 V. With this indicator, the operation of the car will not cause any problems.

So, we figured out how to change the generator to the Gazelle.

Recommended:

Ball pin: purpose, description with photo, specifications, dimensions, possible malfunctions, dismantling and installation rules

When it comes to the ball pin, it means the ball joint of the suspension of the car. However, this is not the only place where this technical solution is applied. Similar devices can be found in the steering, in the guides of the hoods of cars. They all work on the same principle, so the diagnostic and repair methods are the same

GAZelle gearbox and its malfunctions

There is a gearbox on every car. Without it, no vehicle can move even one meter. As you know, at the moment there are several varieties of transmissions. These are robotic boxes, variable, as well as the most popular - automatic and mechanical. However, despite such a variety of species, the main function of the checkpoint remains unchanged

Niva Chevrolet generator: possible malfunctions and repairs

The electronics system is one of the most vulnerable parts of a car. With regular inspection of electrical components, repairs will not be required even throughout the entire operation of the car

Air filter VAZ-2110 and its installation

In order for the car's engine to work stably with maximum performance, it needs a high-quality fuel mixture. One of the most important devices involved in its formation is the air filter - an indispensable element of any engine, be it gasoline or diesel. It is he who provides the carburetor or injector with air, cleaning it from moisture and dust

Nexia speed sensor: self-installation tricks and secrets of its functionality

An important component of the control system is the speed sensor. It is thanks to his work that the driver controls the speed of the car. We will analyze the design features, functioning, diagnostic issues, the most common errors, the algorithm for replacing the sensor with our own hands