2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:09

For the perception of an ordinary person who does not have special knowledge in the field of automotive technology, the device of a car will seem very complicated, but you can still understand and study it, in this article we will talk about KamAZ, or rather, about the structure of the brake system. The KamAZ braking system is a complex mechanism, which today we will try to understand a little.

As in any car, the device of the car consists of the following main parts: the control system of electrical equipment and engine, running gear and transmission, body and engine. So, the KamAZ brake system, let's take a closer look.

The brake system of this car is composed of 5 brake circuits. The device of the KamAZ car: pumping compressed air, the compressor is the main part of the system. From the actuator, the cleaned compressed air is supplied under pressure to the remaining parts of the brake actuator. The part of the drive that feeds it consists of a condensation receiver, a fuse so that the condensate does not freeze, a regulatorpressure and compressor. The brake system of KamAZ is divided into circuits that are autonomous and are separated by protective valves. Regardless of the breakdown, each of them works separately.

The first circuit consists of various brake mechanisms, pipelines and hoses, 2 brake chambers, the lower section of the brake valve, there is also a valve that monitors the control output, a pressure limiting valve. There is a two-pointer pressure gauge and a receiver with a capacity of 20 liters, which has a pressure drop sensor.

The second circuit is the rear bogie brake circuit. It also consists of pipelines and hoses, brake mechanisms of the rear and intermediate axles of the bogie, 4 brake chambers, this circuit has a two-pointer pressure gauge and a valve for the control output of automatic brake forces. The braking device of the trolley also has a receiver with pressure sensors, for draining condensate there are special taps with a total capacity of forty liters, as well as parts of the 3rd protective valve and the upper section of the brake valve.

The third circuit is a circuit with a combined trailer brake drive. It consists of a two-wire trailer brake drive and a sensor, 3 connecting heads and disconnecting valves, a trailer brake control valve with a single-wire drive, and a single safety valve. The third circuit has an accelerator, as well as a double safety valve and other mechanisms.

The fourth circuit does not have its own receiver and iselement of the auxiliary brake system. It consists of hoses and pipelines, a lever drive cylinder that stops the engine, a pneumoelectric sensor. It has 2 damper cylinders, part of a double protection valve, and a pneumatic valve.

The fifth circuit does not have its own receiver, it is an emergency release circuit. It consists of pipelines and hoses, part of the 3rd protective valve, has a pneumatic valve of a two-way bypass valve. Three lines connect the brake drives (pneumatic) of the trailer and the KamAZ vehicle. This is a single-wire drive supply line and a brake line for a two-wire drive. Protects the condensate receiver with a volume of 20 liters from freezing on all KamAZ models.

The KamAZ brake system is rather complicated, but we tried to briefly consider its basic principles.

Recommended:

Brake stand for cars. Stand brake system

How to check the brakes of a car? In order to analyze the state of the brake system, 2 methods are used - road and bench. In our article we will talk about the bench method

Cooling system device. Branch pipes of the cooling system. Replacing the pipes of the cooling system

The internal combustion engine works stably only under a certain thermal regime. Too low a temperature leads to rapid wear, and an excessively high temperature can cause irreversible consequences, up to jamming of the pistons in the cylinders. Excess heat from the power unit is removed by the cooling system, which can be liquid or air

Where and how to pierce brake discs? Grooving of brake discs without removal

The brake system of a car requires regular maintenance. In particular, this applies to replacing brake pads, inspecting discs for defects, changing fluid, etc. But far from always this is done on time and is done at all. Many turn to the service station only in case of obvious malfunctions. But all this can be avoided if you change the pads in a timely manner and do not forget to grind the brake discs

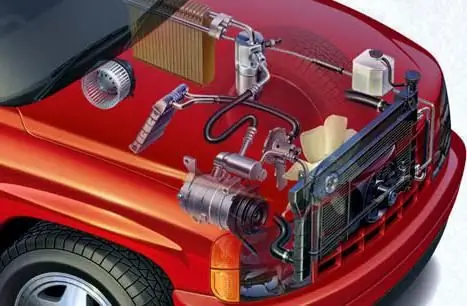

Car air conditioning system: diagnostics, repair, flushing, cleaning, system pressure. How to flush a car's air conditioning system?

The warm season is accompanied by frequent requests from car owners to service shops for such a service as diagnostics of the car's air conditioning system, as well as troubleshooting. We will understand the reasons for this phenomenon

Minimum brake pad thickness. How to determine brake pad wear

The brake system is responsible for the safe braking of the car. The efficiency of the process depends on its serviceability. The number of mechanisms in the brakes is quite large, and all of them should work like clockwork, because the failure of one will entail at least unpleasant consequences. Let's talk about what should be the minimum thickness of the brake pads, as well as how to check for wear