2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:12

Bulldozer is a universal earth-moving equipment that includes in its design a caterpillar or pneumatic wheel tractor with special attachments and controls. Working devices are a blade with knives, a push frame with struts and a drive responsible for lowering and raising the shovel during operation. Some types of machines also have blade adjustment. Consider their features.

Bulldozers: general information

The equipment in question is equipped with a hydraulic drive, attachments, the power consumption of which leaves up to sixty percent of the total power plant (16-20 MPa). This design feature allows you to significantly break into the ground with the help of teeth or a blade. On modern models, separate types of drives are provided that correct the skew and lift the working unit.

A bulldozer is a machine that cuts the soil with its further transportation over short distances (about 100 meters). In addition, the technique is used to remove vegetation, trees, building materials, snow. Also, the unit allows you to perform soil planning, backfilling of ravines and pits, transportationbulk cargo in quarries and warehouses.

Features

Selection and stacking of materials is carried out in warehouses mainly by bulldozers on pneumatic wheels, since caterpillar counterparts deform and pollute the serviced objects.

It is worth noting that the bulldozer is a maneuverable and highly efficient machine with a high cross-country ability. This technique accounts for more than half of the total volume of earthworks.

Aggregates are classified according to the following main features:

- Destination.

- Traction parameters (basic basis).

- View of the running gear.

- Type of screed control.

- Blade configuration.

The definition of "bulldozer" is suitable for general and special purpose vehicles. In the first case, these are machines focused on the development of soils of the 1st-3rd class (all types of earthmoving). Special modifications are operated in special conditions (tractors, pushers, underwater and underground models).

Traction and running parameters

The traction parameters of bulldozers contribute to their division into the following categories (in brackets - the class and power of equipment):

- Super-heavy variants (35th class, power - over 510 kW).

- Heavy models (25-34; 220-405 kW).

- Medium category (6-15; 104-144 kW).

- Light modifications (1, 4-4; 37-95 kW).

- Ultralight class (up to 0.9 class; 18.5-37 kW).

As for the undercarriage, caterpillar and pneumatic wheel variations are distinguished here, as well as a rotary or non-rotary blade. In addition, the control of the working body can be carried out mechanically, hydraulically or pneumatically. The most common models with hydraulics, which has a number of significant advantages over mechanics and pneumatics.

Bulldozer Specifications

Among the main parameters specific to the machines under consideration, the following points are distinguished:

- Weight - up to 106 tons.

- Power plant capacity - up to 600 kW.

- Transport distance when moving soil or rock - 200 meters.

- The maximum blade depth is 80 cm.

- Height with a visor - up to 2, 3 m.

- Blade lift/width/height - 1, 78/6, 1/2, 3m (maximum).

- The length of the working body is up to 5.5 m with a mass reaching about ten tons.

Equipment

On any work shift, the bulldozer is equipped with special loosening equipment, the power of which can reach 368 kW. The working body is intended for destruction of the dense and frozen soil - it separates it from the general massif in the form of blocks with the subsequent leveling. The unit is installed on the back of the tractor base, the front base of which is equipped with the main bulldozer attachment.

A machine with a fixed blade cannot change the position of the working body to the right or left side. Analogs with a rotary unit rotate it in terms of up to 35 degrees to each side.

What is a dump?

The main working equipment of bulldozers is hung in front of the base machine, controlled by a block-type cable system with a single-drum friction winch or a hydraulic unit. The second option uses one or more pumps, pipelines and cylinders.

Also equipment of bulldozers includes a pushing frame, a system for adjusting the working body. The blade is a welded structure, including in the configuration a frontal sheet with a curvilinear outline, a peak, an upper and lower stiffening box, vertical reinforcing ribs and side walls. The rear part of the models with a non-rotating blade is equipped with lugs for connecting the working body with pushers in the form of braces and bars. Rotary analogs are supplied with a ball socket and a fifth, aggregating with a pushing frame. The frontal sheet is welded from a pair of longitudinal elements with a lower flat part and an upper curvilinear counterpart.

Pushers

Bulldozer is a technique equipped with tubular or box section pushing devices. For each unit, as a rule, one brace and a bar are mounted in each direction. The elements are attached from one side to the main frame, and from the other direction - to the blade. Reliability of the connection is ensured by means of lugs, crosses, support pins. For models with a rotary working body, such equipment is a universal platform in the form of a horseshoe, consisting of a pair of identical halves welded in the middle.

In the connecting parts there is a ball heel, and on the opposite side there is a spacer plate. It serves to give additional rigidity to the frame of a universal type. On the upper part of each half, three brackets with lugs are welded to fix the pushers. This design allows you to install the blade in the plan at various angles. The frame also has brackets for attaching hydraulic cylinders.

Blade operation

Replaceable knives (one middle element and a pair of side counterparts) are attached to the lower moldboard. For this purpose, countersunk head bolts are used. The parts are sharpened on both sides, which allows them to be rearranged when dull.

Change of the working body in the plan and the transverse plane is performed mechanically after a complete stop of the equipment. In some designs, a change in position is provided due to hydroficated devices. They are controlled from the operator's cab, without leaving the cab. This significantly reduces the time needed to adjust the blade and develop soils of various densities.

Rippers

What is a bulldozer, we discussed above. Of the working equipment of this machine, it is also worth noting the rippers. The main element of this unit is a tooth, which consists of a landing shank, a tip, a protective pad and fasteners.

Modern devices use racks (as load-bearing parts of bulldozer equipment). They can be of three types: curved, straightor partially curved. Most often there are models of a curved type, since in the process of loosening they experience less tension. At the same time, the elements are prone to jamming when processing medium and large blocks on frozen and dense soil. Straight or slightly curved counterparts are more practical in this regard.

Recommended:

Types of car tinting. Car window tinting: types. Toning: types of films

Everyone knows that different types of tinting make the car more modern and stylish. In particular, dimming the windows in a car is the most popular and popular way of external tuning. The whole advantage of such modernization lies in its simplicity and relatively low cost of the procedure

Contract engine: how to understand what it is? Definition, characteristics, features of work, comparison, pros and cons

If the engine is out of order and it is impossible to overhaul, then the question naturally arises, where and what kind of engine to buy. A contract engine is a good alternative to a new original one and is much better than a used engine from disassembly

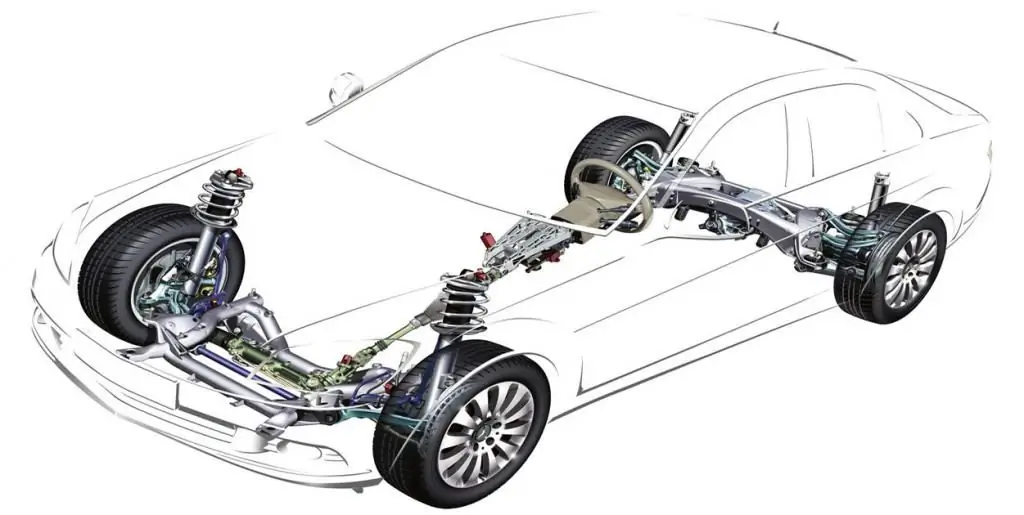

Types of car suspensions: device and diagnostics, features and benefits of various types, reviews

Are many drivers interested in the types of car suspensions? But to know the device of your vehicle, in particular, what parts its chassis consists of, is desirable for certain reasons. This is not only an additional experience, but if necessary, you can take appropriate measures

Autobahn is Definition, features, rules and history

The article tells about the roads that appeared in Germany in the first half of the twentieth century - autobahns. We will talk about the description of these roads, the history of their occurrence, the features of the speed limit and road infrastructure, some rules of the road

Reciprocating internal combustion engine: definition, classification and principle of operation

For more than a hundred years in the world, the main power unit in all wheeled vehicles has been a piston internal combustion engine. Appearing at the beginning of the 20th century and replacing the steam engine, the internal combustion engine in the 21st century remains the most profitable type of motor in terms of economy and efficiency. Let's take a closer look at how this type of internal combustion engine works, how it works, find out what other piston engines are