2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:09

Along with the new trends in the development of "green" technologies, the automotive industry is currently experiencing no less interesting changes in terms of approaches to the development of traditional structural parts of the car. This applies not only to the design of the internal combustion engine and the inclusion of more reliable materials, but also to the control mechanics. So, a few years ago, the dual clutch was considered something experimental and inaccessible to the average car enthusiast, but today this innovation is easy to find in the families of many auto giants, whose production is designed for the mass consumer.

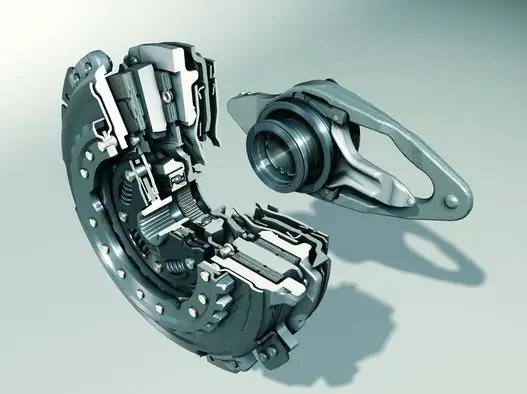

Wet type mechanism

It can be said that the design is a duplicated package of friction mechanisms of a traditional manual gearbox, which are connected to a double shaft, but in different schemes. Part of the discs is mated with the body, and the other part - with the hubs, aggregated with the engine. Each group of gears interacts with one of two shafts - external or internal. The dual-clutch robotic or automatic transmission thus separates the even and odd gear connections according to the type of friction package used. In this case, mechanical work is also carried out through hydraulic cylinders, but under the control of an electro-hydraulic module. The fundamental difference between the “wet” type clutch is that the gears are constantly in the cooling and lubricating fluid.

Dry-type mechanism device

This system provides for the allocation of the leading friction disc, which mates with a dual-mass flywheel. In addition, the working group includes two more disks on the primary shafts of the gearbox, a pair of pressure disks, as well as pairs of bearings and diaphragm springs. A feature of this type of double clutch device is that the friction packs work independently of each other, that is, they do not act mechanically on their surfaces. This separation increases the service life of the mechanism and eliminates the need for frequent use of coolants and lubricants.

Working principle

As soon as the movement starts in first gear, the control automation prepares the second stage. At the moment when the driver shifts gears, the first and second gears will be independently opened and engaged, respectively. Immediately, the on-board computer prepares the next stage for connection as the speed increases. By the way, the principle of operation of the double clutch in modern models has signsintelligent control, which is expressed in the automatic adjustment of the mechanics to the current traffic conditions.

For example, when preparing gears, the computer can take into account several parameters, among which are the speed of rotation of the wheels and transmission shafts, the position of the accelerator (for braking or downshifting), the position of the gear knob, etc. does not occur, therefore, the current torque is not lost, which, in principle, cannot be in the operation of a conventional clutch.

Double Clutch Benefits

A new stage in the practice of developing and implementing designs with two groups of clutch mechanisms is due to several positive aspects at once:

- Fuel economy. Studies show that even compared to a conventional 5-speed automatic transmission, such mechanisms can reduce fuel consumption by 10%.

- Smooth move. Due to the lack of a complete opening of the engine with the drive wheels, it is possible to avoid jerks and vibrations, which also adds to the attractiveness of such mechanisms in the eyes of the consumer.

- Increased dynamics. It should be noted that initially the principle of operation of the clutch with separated groups of friction elements was used on racing cars, also because of the higher speed. But why do you need a double clutch release for an ordinary motorist? On a conventional passenger car, the driver can get not only an increased potential for dynamic capabilities, but also more reliable control. itespecially for models with powerful engines up to 200-300 hp, which become more manageable.

- Possibility of manual and automatic switching. As a rule, the user can use different control modes, including semi-automatic.

Disadvantages of the mechanism

The long journey of dual clutch technology to the mass consumer also had its justification. Some of the negative factors that stopped manufacturers from transferring their cars to this mechanism have survived to this day. The disadvantages of double clutch include primarily structural complexity. With improved alloys, engineers are able to optimize the "stuffing" of the clutch, but the circuitry and configurations still outperform conventional transmissions in terms of maintenance and repair costs. Moreover, it is not always possible to find qualified specialists who can perform high-quality repairs of such a unit.

Also remain the problems of operation in extreme conditions at peak speeds with frequent gear changes. The problem is that the automation gets short periods of time to prepare the next gear, as a result of which there may be quite noticeable "failures" for the driver himself.

Conclusion

The split friction clutch system does not fit into the general trend of the automotive industry, according to which the principles ofreduction in cost, structural compactness, increased reliability and maintainability. On the other hand, dual clutch is a very advantageous solution from the point of view of the average user. Modern cars with such gearboxes allow owners to save fuel and also make the driving process more comfortable. Another thing is that the technology at the mass level of implementation is still quite "raw" and little known. However, specialists from BMW, Ford, Volvo, etc. see the future in this development of automotive clutches.

Recommended:

The principle of operation of the variator. Variator: device and principle of operation

The beginning of the creation of variable programs was laid in the last century. Even then, a Dutch engineer mounted it on a vehicle. After such mechanisms were used on industrial machines

Clutch cylinder VAZ-2107: device, principle of operation, replacement and repair

The use of hydraulic drive in the "seven" is caused by the design features of its clutch. It not only transfers force to the driven disk, but also allows the car to start off smoothly. True, this somewhat complicated the design of the car and its operation. Therefore, it is necessary to know how the VAZ-2107 clutch cylinder is arranged, the principle of its operation and operating features

"Lada-Kalina": ignition switch. Device, principle of operation, installation rules, ignition system, advantages, disadvantages and features of operation

Detailed story about the ignition switch Lada Kalina. General information and some technical characteristics are given. The device of the lock and the most frequent malfunctions are considered. The procedure for replacing with your own hands is described

The principle of the clutch. Car clutch device

Clutch is an integral part of any modern car. It is this node that takes on all the colossal loads and shocks. Particularly high voltage is experienced by devices on cars with a manual transmission. As you already understood, in today's article we will consider the principle of operation of the clutch, its design and purpose

Planetary gearbox: device, principle of operation, operation and repair

Planetary gears are among the most complex gear boxes. With a small size, the design is characterized by high functionality, which explains its widespread use in technological machines, bicycles and caterpillar vehicles. To date, the planetary gearbox has several design versions, but the basic principles of operation of its modifications remain the same