2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:09

The main disadvantage of turbocharged engines in comparison with atmospheric options is less responsiveness, due to the fact that the spin-up of the turbine takes a certain time. With the development of turbochargers, manufacturers are developing various ways to improve their responsiveness, performance and efficiency. Twin scroll turbines are the best option.

General Features

This term refers to turbochargers with dual inlet and double impeller turbine wheel. Since the advent of the first turbines (about 30 years ago), they have been differentiated into open and separate intake options. The latter are analogues of modern twin-scroll turbochargers. The best parameters determine their use in tuning and motorsport. In addition, some manufacturers use them on production sports cars such as Mitsubishi Evo, Subaru Impreza WRX STI, Pontiac Solstice GXP andothers

Design and operation principle

Twin-scroll turbines differ from conventional turbines by having a twin turbine wheel and an inlet part divided in two. The rotor is of a monolithic design, but the size, shape and curvature of the blades vary along the diameter. One part of it is designed for a small load, the other for a large one.

The principle of operation of twin-scroll turbines is based on the separate supply of exhaust gases at different angles to the turbine wheel, depending on the order of operation of the cylinders.

The design features and how the twin scroll turbine works are discussed in more detail below.

Exhaust manifold

The design of the exhaust manifold is of primary importance for twin-scroll turbochargers. It is based on the cylinder coupling concept of racing manifolds and is determined by the number of cylinders and their firing order. Almost all 4-cylinder engines operate in a 1-3-4-2 order. In this case, one channel combines cylinders 1 and 4, the other - 2 and 3. On most 6-cylinder engines, exhaust gases are supplied separately from 1, 3, 5 and 2, 4, 6 cylinders. As exceptions, RB26 and 2JZ should be noted. They work in order 1-5-3-6-2-4.

Consequently, for these motors, 1, 2, 3 cylinders are mated for one impeller, 4, 5, 6 for the second (turbine drive is organized in the stock in the same order). Thus namedthe engines are distinguished by a simplified design of the exhaust manifold, which combines the first three and last three cylinders into two channels.

In addition to connecting the cylinders in a certain order, other features of the manifold are very important. First of all, both channels must have the same length and the same number of bends. This is due to the need to ensure the same pressure of the supplied exhaust gases. In addition, it is important that the turbine flange on the manifold matches the shape and dimensions of its inlet. Finally, the manifold design must be closely matched to the A/R of the turbine for best performance.

The need to use an exhaust manifold of an appropriate design for twin-scroll turbines is determined by the fact that in the case of using a conventional manifold, such a turbocharger will work as a single-scroll one. The same will be observed when combining a single-scroll turbine with a twin-scroll manifold.

Impulsive interaction of cylinders

One of the significant advantages of twin-scroll turbochargers, which determine their advantages over single-scroll ones, is the significant reduction or elimination of the mutual influence of cylinders by exhaust gas impulses.

It is known that for each cylinder to pass all four strokes, the crankshaft must rotate 720 °. This is true for both 4- and 12-cylinder engines. However, if, when the crankshaft is rotated by 720 ° on the first cylinders, they complete one cycle, then on12-cylinder - all cycles. Thus, with an increase in the number of cylinders, the amount of rotation of the crankshaft between the same strokes for each cylinder is reduced. So, on 4-cylinder engines, the power stroke occurs every 180 ° in different cylinders. This is true for intake, compression and exhaust strokes as well. On 6-cylinder engines, more events occur in 2 revolutions of the crankshaft, so the same strokes between the cylinders are 120 ° apart. For 8-cylinder engines, the interval is 90 °, for 12-cylinder engines - 60 °.

It is known that camshafts can have a phase of 256 to 312° or more. For example, we can take an engine with 280° phases at the inlet and outlet. When releasing exhaust gases on such a 4-cylinder engine, every 180 °, the exhaust valves of the cylinder will be open for 100 °. This is required to lift the piston from bottom to top dead center during exhaust for that cylinder. With the 1-3-2-4 firing order for the third cylinder, the exhaust valves will begin to open at the end of the piston stroke. At this time, the intake stroke will begin in the first cylinder, and the exhaust valves will begin to close. During the first 50° of the opening of the exhaust valves of the third cylinder, the exhaust valves of the first cylinder will open, and its intake valves will also begin to open. Thus, the valves overlap between the cylinders.

After the removal of exhaust gases from the first cylinder, the exhaust valves close and the intake valves begin to open. At the same time, the exhaust valves of the third cylinder open, releasing high-energy exhaust gases. Significant sharetheir pressure and energy is used to drive the turbine, and a smaller part is looking for the path of least resistance. Due to the lower pressure of the closing exhaust valves of the first cylinder in comparison with the integral turbine inlet, part of the exhaust gases of the third cylinder is sent to the first.

Due to the fact that the intake stroke begins in the first cylinder, the intake charge is diluted with exhaust gases, losing power. Finally, the valves of the first cylinder close and the piston of the third rises. For the latter, the exhaust is carried out, and the situation considered for cylinder 1 is repeated when the exhaust valves of the second cylinder are opened. Thus, there is confusion. This problem is even more pronounced on 6- and 8-cylinder engines with exhaust stroke intervals between cylinders of 120 and 90 °, respectively. In these cases, there is an even longer overlap of the exhaust valves of the two cylinders.

Due to the impossibility of changing the number of cylinders, this problem can be solved by increasing the interval between similar cycles by using a turbocharger. In the case of using two turbines on 6- and 8-cylinder engines, cylinders can be combined to drive each of them. In this case, the intervals between similar exhaust valve events will double. For example, for the RB26, you can combine cylinders 1-3 for the front turbine and 4-6 for the rear. This eliminates the successive operation of the cylinders for one turbine. Therefore, the interval between exhaust valve events forcylinders of one turbocharger increases from 120 to 240°.

Due to the fact that the twin scroll turbine has a separate exhaust manifold, in this sense it is similar to a system with two turbochargers. So, 4-cylinder engines with two turbines or a twin-scroll turbocharger have an interval of 360 ° between events. 8-cylinder engines with similar boost systems have the same spacing. A very long period, exceeding the duration of the valve lift, excludes their overlap for the cylinders of one turbine.

This way, the engine draws in more air and draws out the remaining exhaust gases at low pressure, filling the cylinders with a denser and cleaner charge, resulting in more intense combustion, which improves performance. In addition, greater volumetric efficiency and better cleaning allow the use of a higher ignition delay to maintain peak cylinder temperatures. Thanks to this, the efficiency of twin-scroll turbines is 7-8% higher compared to single-scroll turbines with a 5% better fuel efficiency.

Twin-scroll turbochargers have higher average cylinder pressure and efficiency, but lower peak cylinder pressure and outlet back pressure, compared to single-scroll turbochargers, according to Full-Race. Twin-scroll systems have more backpressure at low rpm (promoting boost) and less at high rpm (improving performance). Finally, an engine with such a boost system is less sensitive to the negative effects of wide-phasecamshafts.

Performance

Above were the theoretical positions of the functioning of twin-scroll turbines. What this gives in practice is established by measurements. Such a test by comparison with the single-scroll version was carried out by DSPORT magazine on the Project KA 240SX. His KA24DET develops up to 700 hp. With. on wheels on the E85. The motor is equipped with a custom Wisecraft Fabrication exhaust manifold and a Garrett GTX turbocharger. During the tests, only the turbine housing was changed at the same A / R value. In addition to power and torque changes, testers measured responsiveness by measuring the time it took to reach certain rpm and boost pressure in third gear under similar launch conditions.

The results showed the best performance of the twin-scroll turbine throughout the entire rpm range. It showed the greatest superiority in power in the range from 3500 to 6000 rpm. The best results are due to the higher boost pressure at the same rpm. In addition, more pressure provided an increase in torque, comparable to the effect of increasing the volume of the engine. It is also most pronounced at medium speeds. In acceleration from 45 to 80 m / h (3100-5600 rpm), the twin-scroll turbine outperformed the single-scroll one by 0.49 s (2.93 vs. 3.42), which will give a difference of three bodies. That is, when a car with a signal-scroll turbocharger reaches 80 mph, the twin-scroll variant will travel 3 car lengths ahead at 95 mph. In the speed range of 60-100 m/h (4200-7000 rpm), the superiority of the twin-scroll turbineturned out to be less significant and amounted to 0.23 s (1.75 versus 1.98 s) and 5 m/h (105 versus 100 m/h). In terms of the speed of reaching a certain pressure, a twin-scroll turbocharger is ahead of a single-scroll turbocharger by about 0.6 s. So at 30 psi the difference is 400 rpm (5500 vs 5100 rpm).

Another comparison was made by Full Race Motorsports on a 2.3L Ford EcoBoost engine with a BorgWarner EFR turbo. In this case, the exhaust gas flow rate in each channel was compared by computer simulation. For a twin-scroll turbine, the spread of this value was up to 4%, while for a single-scroll turbine it was 15%. Better flow rate matching means less mixing loss and more impulse energy for twin-scroll turbochargers.

Pros and cons

Twin scroll turbines offer many advantages over single scroll turbines. These include:

- increased performance throughout the rev range;

- better responsiveness;

- less mixing loss;

- increased impulse energy to the turbine wheel;

- better boost efficiency;

- more bottom end torque similar to twin-turbo system;

- reduction of intake charge decay when valves overlap between cylinders;

- lower exhaust gas temperature;

- reduce impulse losses of the motor;

- reduce fuel consumption.

The main disadvantage is the great complexity of the design, causing increasedprice. In addition, at high pressure at high speeds, the separation of the gas flow will not allow you to get the same peak performance as on a single-scroll turbine.

Structurally, twin-scroll turbines are analogous to systems with two turbochargers (bi-turbo and twin-turbo). In comparison with them, such turbines, on the contrary, have advantages in cost and simplicity of design. Some manufacturers are taking advantage of this, such as BMW, which replaced the twin-turbo system on the N54B30 1-Series M Coupe with a twin-scroll turbocharger on the N55B30 M2.

It should be noted that there are even more technically advanced options for turbines, representing the highest stage of their development - turbochargers with variable geometry. In general, they have the same advantages over conventional turbines as twin-scroll, but to a greater extent. However, such turbochargers have a much more complex design. In addition, they are difficult to set up on motors not originally designed for such systems due to the fact that they are controlled by the engine control unit. Finally, the main factor causing the extremely poor use of these turbines on gasoline engines is the very high cost of models for such engines. Therefore, both in mass production and in tuning, they are extremely rare, but they are widely used on diesel engines of commercial vehicles.

At SEMA 2015, BorgWarner unveiled a design that combines twin scroll technology with variable geometry design, the Twin Scroll Variable Geometry Turbine. In hera damper is installed in the double inlet part, which, depending on the load, distributes the flow among the impellers. At low speeds, all the exhaust gases go to a small part of the rotor, and the large part is blocked, which provides even faster spin-up than a conventional twin-scroll turbine. As the load increases, the damper gradually moves to the middle position and evenly distributes the flow at high speeds, as in a standard twin-scroll design. Thus, this technology, like variable geometry technology, provides a change in the A / R ratio depending on the load, adjusting the turbine to the engine's operating mode, which expands the operating range. At the same time, considering the design is much simpler and cheaper, since only one moving element is used here, working according to a simple algorithm, and the use of heat-resistant materials is not required. It should be noted that similar solutions have been encountered before (for example, quick spool valve), but for some reason this technology has not gained popularity.

Application

As noted above, twin-scroll turbines are often used on mass-produced sports cars. However, when tuning, their use on many motors with single-scroll systems is hampered by limited space. This is primarily due to the design of the manifold: at equal lengths, it is necessary to maintain acceptable radial bends and flow characteristics. In addition, there is a question of the optimal length and bend, as well as the material and wall thickness. According to Full-Race, due to greater efficiencytwin-scroll turbines, it is possible to use channels of a smaller diameter. However, due to their complex shape and double inlet, such a collector is in any case larger, heavier and more complicated than usual due to the greater number of parts. Therefore, it may not fit in a standard place, as a result of which it will be necessary to change the crankcase. In addition, twin-scroll turbines themselves are larger than similar single-scroll ones. In addition, other appipe and oil trap will be required. In addition, two wastegates (one per impeller) are used instead of a Y-pipe for better performance with external wastegates for twin scroll systems.

In any case, it is possible to install a twin-scroll turbine on a VAZ, and replace it with a Porsche single-scroll turbocharger. The difference lies in the cost and scope of work on preparing the engine: if on serial turbo engines, if there is space, it is usually enough to replace the exhaust manifold and some other parts and make adjustments, then naturally aspirated engines require much more serious intervention for turbocharging. However, in the second case, the difference in installation complexity (but not in cost) between twin-scroll and single-scroll systems is insignificant.

Conclusions

Twin-scroll turbos provide better performance, responsiveness and efficiency than single-scroll turbos due to the separate exhaust gas supply to the dual turbine wheel and the elimination of the mutual impulse influence of the cylinders. Howeverbuilding such a system can be very costly. All in all, this is the best solution to improve responsiveness without sacrificing maximum performance for turbo engines.

Recommended:

Electro-turbine: characteristics, principle of operation, pros and cons of work, do-it-yourself installation tips and owner reviews

Electric turbines represent the next stage in the development of turbochargers. Despite significant advantages over mechanical options, they are currently not widely used on production cars due to the high cost and complexity of the design

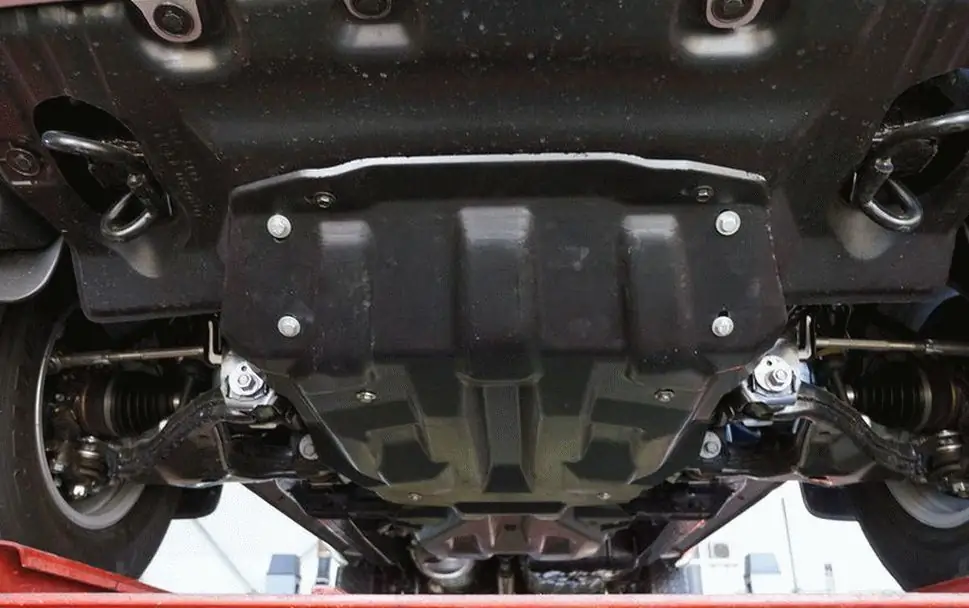

Composite crankcase protection: characteristics, principle of operation, pros and cons

The need to install crankcase protection has not been disputed by car owners for a long time. The bottom of the car covers various important units, including the transmission, transfer case, engine crankcase, chassis components and parts, and much more. Hitting any obstacles can damage them. To avoid this, crankcase protection is installed - metal or composite

CVT transmission: principle of operation, owner reviews on the pros and cons of the variator

When buying a car (especially a new one), many motorists face the question of choosing a gearbox. And if everything is more or less clear with engines (diesel or gasoline), then the choice of transmissions is simply huge. These are mechanics, automatic, tiptronic and robot. Each of them works in its own way and has its own design features

Multi-link suspension: description, principle of operation, pros and cons

Now different types of suspensions are installed on cars. There is dependent and independent. Recently, a semi-independent beam at the rear and a MacPherson strut at the front have been installed on budget-class cars. Business and premium cars have always used independent multi-link suspension. What are the pros and cons of her? How is it organized? All this and more - further in our today's article

Air suspension: principle of operation, device, pros and cons, owner reviews. Air suspension kit for car

The article is about air suspension. The device of such systems, types, principle of operation, pros and cons, reviews, etc. are considered