2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:16

The car uses a lot of technical elements. One of these is the wheel bearing. UAZ is also equipped with them. It is an integral part of any car. After all, it is this bearing that ensures smooth rotation of the driving and driven wheels around the axis. This node is under enormous load. Therefore, it is possible that the UAZ front hub bearing may fall apart. What is the resource of this element, what are the signs of failure and how to replace it? All this - later in our article.

Resource

On average, the service life of this element is approximately 150 thousand kilometers.

But it is worth noting that this figure may differ significantly. On one UAZ Patriot car, the hub bearing can last up to 300 thousand, and on the other it can fall apart by 40.

Why sohappening?

The destruction of the bearing occurs in most cases due to lack of lubrication. She can be washed out of the cage. This happens especially often on cars that are used on off-road. When crossing the next ford, water enters not only the bridges and the box, but also the UAZ hub bearing. As a result, the element works "dry". In addition, the UAZ hub bearing fails in the presence of solid contaminants. Dust and dirt will work as an abrasive in the clip. High load is also the cause of failure of the wheel bearing. If the machine is frequently used on rough terrain, be prepared for an upcoming bearing change. Also, the element does not like large pits. Even on off-road high-profile tires, all the bumps should be handled very carefully. The hub bearing does not like sloppy driving. In addition, shocks are transmitted to other suspension elements. These are shock absorbers and silent blocks of levers (in the case of the Patriot front suspension).

In rare cases, the cause of a breakdown is a factory defect. That is why the UAZ hub bearing (number 127509 in the catalog) falls apart by 30 thousand, although it contains a very different resource.

Proper installation is the key to a high resource

What should I do if the element fails again after replacement? And not after 30, but 3 thousand kilometers? It's all about the wrong installation. This is one of the common reasons wheel bearings fail. If you install the element at the wrong angle (obliquely), then the loadper clip will increase many times. In this case, the part will collapse already in the first thousand kilometers.

Another important point is the tightening force. If, when replacing, the master tightened the bearing nut tightly, the loads on it will also increase several times. The part will get hot all the time. As a result, UAZ will need to replace the hub bearing again.

How to determine wear?

Since this element interacts with the hub, the failures will be associated with the wheel. Determining a bearing failure is quite simple. On the move, you will hear a “dry crunch” (this is how spherical mechanisms roll). This means that the inner race is broken and the needles spin unevenly. This sound will get stronger over time.

In addition, a malfunction may be accompanied by vibrations. They can be transmitted to the steering wheel and to the body itself. Driving such a car is extremely dangerous, as there is a risk of a wheel wedge. At high speed, this can cause an uncontrolled skid.

If you continue to ignore the problem, the car will start to pull in one direction. You will have to constantly catch the steering wheel in order to continue straight ahead.

How to replace? Removing the hub

Fortunately, the design of Ulyanovsk-made SUVs is quite simple. Therefore, you can replace the UAZ rear hub bearing with your own hands. So let's get to work.

First, we need to jack up part of the car, having previously torn offwheel bolts. The car is put on the handbrake. Additionally, it is recommended to install wheel chocks. To remove the bearing, you will have to remove the entire hub. First, remove the brake disc. Next, unscrew the three fixing screws that go to the cap of the wheel off clutch. We remove these elements and turn out the six bolts of the coupling itself. In this case, you need to fix the hub with a mounting spatula. Otherwise, it will scroll during the dismantling of elements. After removing the coupling, we bend the tab of the lock washer and unscrew the lock nut of the hub itself. Next, remove the washer with a minus screwdriver. Unscrew the hub nut and the hub assembly itself.

Replacing the bearing

So, the hub is in hand - it remains only to remove the old element and install a new one. To do this, we take a screwdriver in our hands and remove the inner ring of the hub. The last element is also taken out. Please note that to dismantle the element, you will have to remove the gland. It is disposable and cannot be reinstalled. At the next stage, we remove the thrust washer of the hub seal and unscrew the inner bearing ring.

All removed elements should be degreased - you can use gasoline or soak the element in kerosene. When installing a new hub bearing on the UAZ, pay attention to the condition of the elements mated with it. The presence of potholes, scratches and other signs of wear is unacceptable. When replacing, both the inner and outer wheel bearings are replaced.

To extrude an old element, you shoulduse a puller. Gently squeeze the antennae of the inner and outer retaining ring and pull the parts out.

Installation

It is not allowed to install the element with a hammer or other improvised elements. To avoid distortion, use a mandrel. We will press in new bearing rings with it. After successful installation, the quality of the fit of the element should be re-checked. The bearing rings must not turn by hand. Further assembly is carried out in the reverse order.

Important point: watch the bearing tightening torque. The adjustment nut must be tightened with a torque of 30 to 40 Nm. Turn the wheel on the jacked up car by hand - it should rotate easily. In this case, a small backlash is allowed. It is not necessary to tighten the adjusting nut all the way - there should be a thermal clearance for the bearing.

Helpful advice

Before installing the bearing, check the quality of the lubrication of the "needles". Often manufacturers do not report lubrication. Because of this, the resource drops significantly. As for the type of lubricant, you need to use only specialized - for wheel bearings. The usual "Litol" or "graphite" will not work.

Conclusion

So, we found out how to replace the hub bearing on a UAZ car on our own and what are its symptoms of a malfunction. In order to eliminate premature wear, it is worth providing the needle element with high-quality lubrication and eliminating distortions during installation.

Recommended:

Chevrolet Niva front hub bearing replacement. Replacement Tips and Tricks

Did you decide to replace the front hub bearing on the Chevrolet Niva? Then this article is especially for you. Here are tips and tricks for replacing the bearing yourself

Front hub design and do-it-yourself bearing replacement

The front hub ensures the wheels turn and rotate around their own axis. This is typical for any car, regardless of the type of drive - front or rear. The only thing that is present in the hubs of cars with front-wheel drive is more powerful bearings, since a CV joint is installed on them

Rear hub bearing for VAZ-2108: dimensions

The article talks about what constitutes a rear hub bearing on the VAZ-2108. The design of the part, modifications, dimensions are given. Do-it-yourself replacement process described

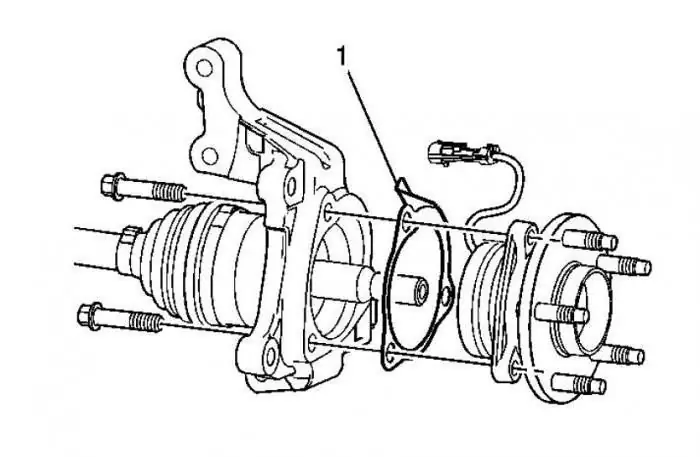

Support bearings of the front struts: photo, signs of malfunction. How to replace the front strut bearing?

Information about what constitutes the support bearings of the front struts. The design, principle of operation are described, as well as instructions for replacing these suspension elements

What is a rear wheel bearing, how does it work and how to replace it?

The running system performs many functions, the main of which is to ensure vehicle controllability. To make the machine maneuverable and safe, it is equipped with a special steering knuckle and a hub between the axles. In order for them to be as reliable as possible, they include two bearings each. Both parts may differ in size and cost, but their design remains unchanged