2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:09

Gazelle cars have been produced since 1994 and during this time have undergone many changes. At different times, they used different methods for determining speed.

First option

Early cars were equipped with a mechanical speedometer driven by a flexible shaft model GV 310. The flexible shaft was mounted at one end on the gearbox housing, the other was attached to the speedometer housing. The drive was carried out from a helical gear mounted on the secondary shaft in the gearbox. It is located closer to the rear shaft bearing.

The Gazelle's speed sensor in this case was the device itself for measuring speed. The flexible shaft rotated the magnetic disk, creating a magnetic field. Its intensity depended on the frequency of rotation of the shaft. This field turned the spring-loaded arrow. Speedometer drive cable "Gazelle" in the photo.

Maintenance of the drive consisted of timely lubrication of rotating units and control over the cable run. Cable bending radii should not exceed 150 mm.

Restyled variant

Since 2003, cars have been equipped with a new instrument cluster with an electronic speedometer. The new Gazelle speed sensor receiveddesignation DS-6 and was installed on the gearbox housing on the left side. The sensor had a mechanical drive by analogy with a cable. The Gazelle Business used the same device.

The sensor is based on the principle of the Hall effect. Any change in speed is detected by the sensor and transmitted in the form of voltage pulses to the controller of the electronic control unit. They have a lower limit of about 1 volt and an upper limit of at least 5 volts.

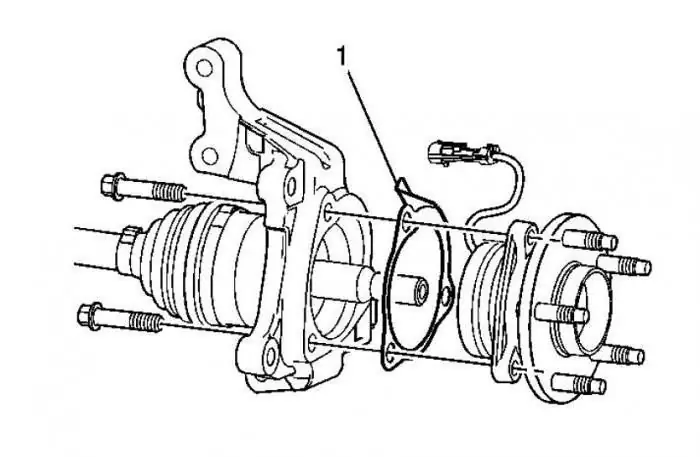

There is a proportional relationship between the speed and pulse frequency, so the sensor error is small. With an increase in speed, the frequency of pulses also increases, but there is a design limitation in the sensor - the readings of the pulse counter cannot be higher than 6004 per one kilometer of run. The controller calculates the speed from the number of pulses and the time intervals between them. The received signal is transmitted to the speedometer located on the dashboard of the car. The photo shows the Gazelle electronic sensor.

The design of the sensor is quite simple and, in general, it does not bring problems to car owners. Replacing the Gazelle Business speed sensor is quite simple. Before starting work, it is advisable to disconnect the battery from the vehicle's on-board network. To remove the sensor, it is necessary to remove the hatch located next to the gearshift rocker. The sensor can also be accessed from below. To loosen the fixing nut, a wrench with a 22 mm opening is required. After loosening the nut, the sensor can be easily unscrewed by hand and removed from the actuator. On the other hand, it is equipped with the usualconnector with plastic latches.

Sometimes there is an oil leak through the sensor drive, which oiles the contacts and disrupts operation. The drive itself is fixed with a clamping bracket, to remove which it is necessary to unscrew one 10 mm bolt. After that, the drive can be removed from the crankcase of the box to replace the annular rubber gasket.

Third option

The Gazelle Next speed sensor is somewhat different from previous models. It is electromagnetic and has four wires going to the controller. Previous sensors had only three wires. The device is a new type in the photo.

The sensor is part number A63R42.3843010-01, fitted with a 22mm nut on the body and screwed into the gearbox housing.

Recommended:

Idle speed sensor on the VAZ-2109 (injector): where is it located, purpose, possible malfunctions and repairs

In injection cars, a power system is used that is different from the carburetor with its channel for idling the engine. To support the operation of the engine in XX mode, an idle speed sensor, the VAZ-2109 injector, is used. Experts call it differently: XX sensor or XX regulator. This device practically does not cause problems to the car owner, but sometimes it still fails

Chevrolet Niva front hub bearing replacement. Replacement Tips and Tricks

Did you decide to replace the front hub bearing on the Chevrolet Niva? Then this article is especially for you. Here are tips and tricks for replacing the bearing yourself

Speed sensor and everything about it

Speed sensor - a part that controls the speed of the vehicle. She deserves special attention

Idle speed sensor - purpose and function

Any car is made up of many parts. Each of them carries a function, and a malfunction of at least one mechanism can lead to a series of breakdowns. One of the important details is the idle speed sensor, which will be discussed in the article

Temperature sensor VAZ-2106: device, principle of operation, replacement

Despite the fact that the VAZ-2106 car has a carburetor power system, there are still sensors in the car. They measure the pressure and temperature of the coolant. Let's talk about the temperature sensor VAZ-2106. It is installed in the car's cooling system and is connected to the temperature scale in the cabin