2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:18

Slinging loads is a technological process, which is a tying and hooking of heavy loads for their further lifting and moving. It is used everywhere, since only in this way can indivisible loads such as pipes or beams be lifted and carried. However, you should pay attention to the fact that slinging is not a random action, you cannot tie the loads the way you want. There are both international standards and domestic GOST, it is according to them that slinging should be carried out. At any time, the truck driver can be stopped and checked for correct strapping - but this is more important at the loading points, since often the cargo goes through the procedure only there, and on the road it is already placed in a completely different way. In any case, you need to know all the cargo slinging schemes, as they will be very useful to you in the production of loading operations.

Pipes and shafts

If we consider cargo slinging schemes, then you need to start with pipes, since this process is most important for this type of cargo. There are about ten different types of slinging in total, depending on how many pipes you need.load and what they are. For example, if the length of the pipes is less than one and a half meters, then a choke sling is used when one knot is made along the center of gravity, usually no more than one turn is made. If the pipes are long, then it all depends on the devices that are used. If you have one universal ring sling, you need to use the double-ended choke method, otherwise the center of gravity will be too unstable. If you have two slings, then the pipe is fastened with standard wrapping. There is also a less common version of fastening with two chokes. Pay attention also to branch slings with end grips - they are convenient to use. Slinging and warehousing schemes can be very diverse, but all of them have been developed for a long time, and their effectiveness has been tested by time.

Special pipe slinging methods

It's worth talking about special situations when you need unusual cargo slinging schemes. Posters with such diagrams, of course, should always be present at the site of the operation, so that workers can navigate them and act exactly in accordance with all standards. Of course, you can also use a tong or traverse equipped with textile straps, if you have such devices. Well, if you need to load a whole package of pipes at once, then here you will definitely need a traverse with slings, which are also equipped with hooks. This is how cargo slinging schemes look like,consisting of one or more pipes.

Metal rolling

Slinging schemes for rolled metal, of course, are very different from those used for pipes. For example, for a channel you need to use two universal loop slings that need to be fixed in the girth, and for an I-beam, a two-leg sling, which is also fixed in the girth. Please note that in both cases, you need to use spacers to secure the load more securely. Separately, it is worth talking about bundles of channels and corners, which are sometimes very difficult to pack properly. In the first case, you need to use three lines at once - two of them should be universal ring, and one should be two-branch. And at the same time, do not forget that in this case you still need to make a few wire strapping rings, as well as add a gasket under the universal slings so that they do not harm the channels. If we are talking about corners, then here you can do without a two-branch sling, but otherwise everything remains the same - two universal slings, wire harness and lining. So here are typical cargo slinging schemes that you need to follow if you want to achieve a good result without exposing either workers or cargo to danger.

Slinging metal sheets

If you are thinking about how cargo slinging diagrams are depicted, DWG drawings are the answer - this is a special type of drawings, onwhere you can see all the details of the process. But it's worth getting back to the metal weights that you might have to ship. Most of the rolled metal is sheets that can be slinged both vertically and horizontally. To begin with, it is worth talking about the more popular horizontal slinging. To do this, you will need a branch sling equipped with a special grip. If we are talking about a whole package of sheets that are packed horizontally, then the grip will not save here - you need to use two universal loop slings in the girth, and not forgetting about the spacers. If you have a special four-leg sling with clamps, then it is suitable for loading single sheets, as well as for whole packages. As for the vertical slinging of sheets, there are special eccentric grippers for single sheets. For packages, you will also need to use special vertical grips that will be installed on the sides of the package, and universal loop slings will be attached to them. As you can see, slinging and warehousing schemes are far from the easiest issue that needs to be studied very carefully.

Parts and equipment

Very often you have to load large indivisible parts of large mechanisms or entire pieces of equipment, and for this there are also GOST standards - slinging schemes for goods of this kind must also be present at the loading sites. So, it’s worth starting with the simplest - from the body part. For its slinging you will needjust two universal loop slings that need to be secured with a girth. The situation with vessels is a little more complicated, since they need to be processed in a vertical position. But this does not change much - you will need to use the same two loop slings, but fasten them with a girth to the parts protruding around the perimeter. Even if loading occurs in a horizontal position, the tactics remain the same. Sometimes there are situations in which the equipment is delivered in a large wooden container - in this case you will have to try a little more. Here you will need a four-branch sling, equipped with hooks, for which you can hook two universal loop slings, threaded under the container. Bulk pulleys and flywheels are also very easy to sling using one or two universal slings, depending on whether you want to load them vertically or horizontally. As for various valves and taps, they need to be slinged in the same way as pulleys, but at the same time, engagement should be made by the flange, if possible, passing the slings directly through the torsional part of the valve. Well, if we are talking about large units, then we can no longer do without special mounting loops, which are connected with a cotter pin lock with rigging brackets. And looped slings are already attached to them. Now you can fully imagine how diverse cargo slinging schemes are - tying methods, hooks, and so on can be very different for different types of cargo.

Timber

If speechWhen it comes to timber, it is immediately worth highlighting logs and boards - there are different slinging methods for them. For the log pack, you will need a two-leg sling with hooks, as well as two universal ring slings that are attached with a loop. As a matter of fact, for a package of lumber, such as boards, practically nothing changes - the principle remains the same.

Reinforced concrete slabs

Reinforced concrete slabs are a fairly broad area in terms of slinging, as various factors can be involved. For example, a lot depends on whether there are mounting loops in the plates so that the hooks of the sling can be hooked on them. If not, then you will need a sling with special clamps. Things are quite different when it comes to the presence of mounting windows in the slab, but they are far from always available, as well as mounting loops.

Reinforced concrete structures

As in the case of plates, other structures are attached mainly by mounting loops, since in most cases they are available - without them, loading would be very difficult. For special occasions such as a farm, a special traverse equipped with balancing blocks can be used.

Compliance with standards

It is very important that the slinging is carried out in full accordance with the standards. To do this, all the necessary posters and diagrams must be at the site of the operation, and the process itself must be constantly monitored.

Recommended:

Increasing car engine power: instructions and possible ways

Every year cars are getting faster and more powerful. Manufacturers are trying to get the most out of engines. Various methods and technologies are used for this. But what if you want to increase the engine power of an already used car? Consider a few effective options

How to polish a car: ways, means and recommendations

The paintwork (LKP) of the car released from the factory is in perfect condition. But external factors contribute to its constant deterioration. Exposure to moisture, direct sunlight, scratches, etc., all cause loss of gloss. But you can restore its former appearance with the help of polishing. Moreover, it is not necessary to give the car to specialists, because you can handle it yourself, but first you need to learn how to polish the car. There are a whole host of nuances, each of which plays an important role

Forklifts - a universal tool for placing goods in a warehouse

Forklifts - special floor-type warehouse transport. Designed for moving, stacking and system stacking of various cargoes, goods and materials

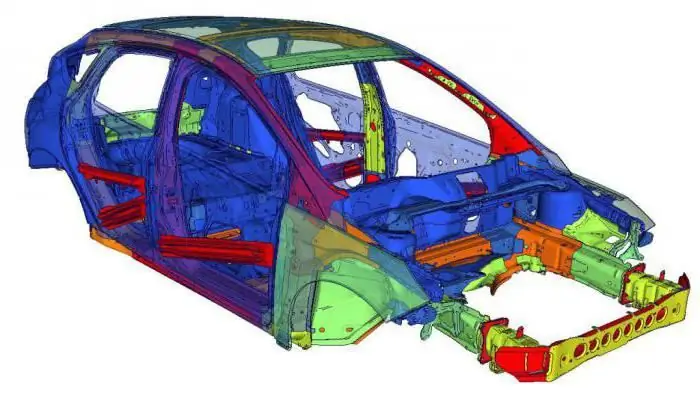

Car: how it works, the principle of operation, characteristics and schemes. How does a car muffler work?

Since the creation of the first gasoline-powered car, which happened more than a hundred years ago, nothing has changed in its main parts. The design has been modernized and improved. However, the car, as it was arranged, remained as such. Consider its general design and arrangement of some individual components and assemblies

Cargo is The meaning of the word "cargo"

Cargo is a concept that can be explained in completely different ways. And if you are interested in its interpretation, I advise you to read this article