2026 Author: Erin Ralphs | [email protected]. Last modified: 2025-01-22 21:14:16

When overhauling an engine, questions often arise about choosing the right thermal gap. Piston rings with too much clearance in the lock and along the axis will not work correctly. But even worse if the gap was taken too small. In this case, the engine will not work for a long time and after a few thousand kilometers it will again ask for a bulkhead. Let's talk about how to choose the correct thermal clearance of piston rings and what it should ideally be.

General information and concepts

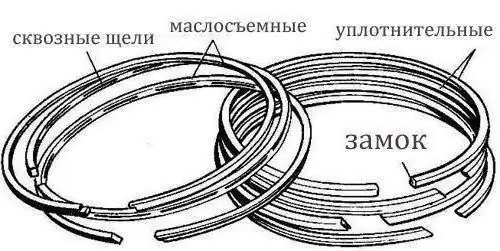

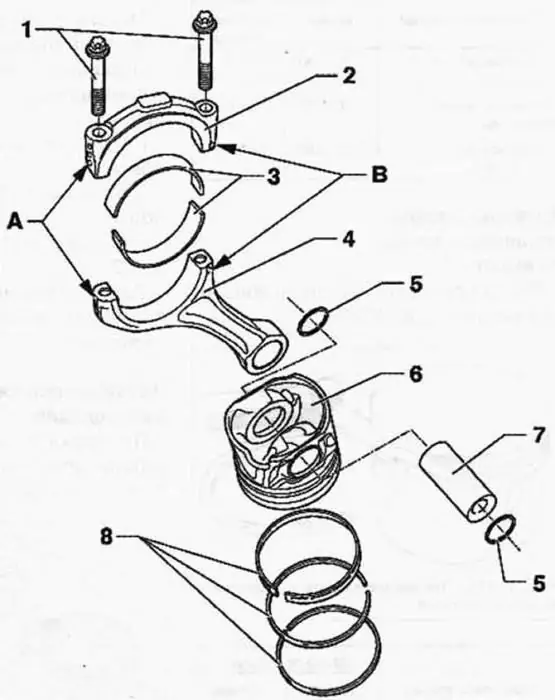

The piston consists of three rings, each of which performs its specific function. The top two are used to maintain compression in the engine. If they lie or reach a critical level of wear, then the dynamic characteristics of the internal combustion engine decrease, oil consumption increases and other problems arise. The bottom ring is called the "oil scraper". From the name it is quite clear its purpose induring the operation of the power unit.

Metal parts expand when an internal combustion engine is running. For this simple reason, the thermal clearance of the piston rings is reduced. If it was initially chosen incorrectly, that is, less than acceptable, then when the operating temperature of the motor is reached, the piston will scratch the cylinder walls.

What is the thermal clearance of the VAZ piston rings?

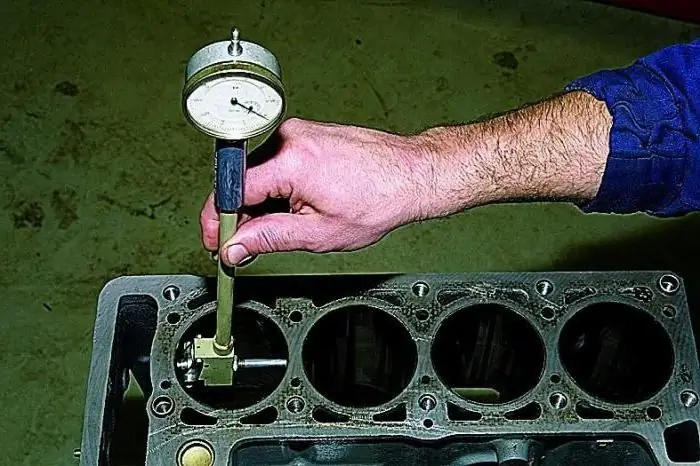

Before we go directly to the numbers, I would like to note that the gap measurement should be performed on an unheated part. In this case, be sure to place the ring in the cylinder. To determine the parameter, special probes or strips are used. In most cases, the allowable gap value ranges from 0.25 to 0.5 mm. But depending on the type of motor and its modification, these data may differ, so it is recommended to first check the documentation of the internal combustion engine.

What thermal clearance of piston rings should be on VAZ cars? For compression rings, it should be in the range of 0.25-0.4 mm, and for the oil scraper ring - 0.25-0.5 mm. Again, these figures may vary slightly, so you need to focus on a specific engine model.

Measuring technology

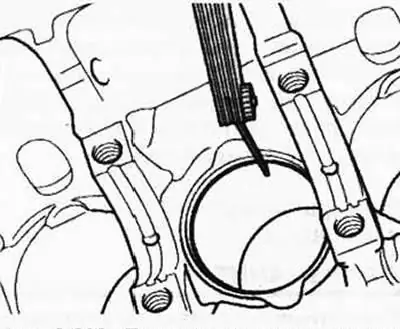

The first thing to do is bring the ring to the side of the cylinder. Then place its outer part in the allotted groove. Next, you need a set of slats, with the help of which the gap is determined. If the ring is located directly inside the cylinder, then measurements are necessarycarry out separately, as the distance between the ends may vary.

The first thing to do is put the piston ring in the engine oil. The quality of the latter does not really matter here, since absolutely everything will burn during operation. Further, the ring moves along the wall of the cylinder. Moreover, this must be done only in the cylinder where this ring will be used in the future. It is especially convenient to carry out such a calculation if the piston has already been dismantled. In the case of a recent turning of the block, it is enough to move the ring by 3-5 mm, approximately to the place where it will be located during the operation of the internal combustion engine. After that, we use a set of probes (bars) and get the necessary values. Use the "manual" when selecting the piston ring clearance. Diesel "Ford Escort" 1.6, for example, should have a gap of 0.3-0.5 mm for the upper compression rings and 0.2-0.45 mm for the oil scraper.

Complex repair of CPG

The so-called "capital" of the engine implies a complete troubleshooting of the cylinder-piston group, because it is it that is subject to the greatest thermal loads during operation. Consequently, pistons, compression and oil scraper rings are also subject to increased wear. In some cases, when the rings have not yet reached critical wear, they are left. On most modern internal combustion engines, a gap of 1 mm is already considered critical, in which case it is necessary to replace the rings. So, when overhauling the engine, it is recommended to change all the rings on the pistons, evenif they fit. This is necessary in order not to disassemble the motor again after 50,000 kilometers.

It should also be understood that the gap for the first and second compression rings is not always the same. A vivid example of this is domestic heavy equipment. For example, the thermal clearance of KamAZ piston rings should look like this:

- first compression ring - 0.20-0.40mm (new);

- second - 0, 30-0, 50 (new);

- oil scraper 0, 25-0, 50 (new).

At the same time, the allowable wear for all types of rings should not exceed 1 mm. Even 0.9 mm can already be considered critical. Although it is often clear without disassembling the CPG that the rings are asking for a replacement.

Increased oil consumption

Most modern car manufacturers are increasing piston ring clearances in their engines. If for some types of internal combustion engines 1 mm is critical, but on a new engine from "BVM" or "Audi" 1-2 mm is the gap of new engine rings without mileage. Here it is necessary to deal with one important point.

The fact is that during the combustion of the fuel-air mixture, gases are formed that enter the piston groove. Accordingly, they begin to create pressure from the inside of the ring, ensuring that it is pressed against the cylinder wall.

That is why when the internal combustion engine is running at idle and low speeds, the downforce is not as large as at high loads. This is due to the fact that the amount of gases in the combustion chamberis significantly different. The second compression ring partly performs the task of an oil scraper, removing the film from the cylinder. If it is worn out, then the lubricant consumption increases significantly, especially at idle and low engine speeds.

Thermal clearance of piston rings VAZ-21083

The domestic car 2108, better known as the "eight" or "chisel", cannot boast of an extremely reliable engine. Although he, with proper maintenance, runs quite a lot. Nevertheless, during a major overhaul, special attention must be paid to the thermal gap. Many do not attach any importance to this and leave the old rings. But such a major overhaul will not bring the expected results, especially if the engine was overhauled due to increased oil consumption.

There are several salient features here. In particular, the maximum allowable clearance in all rings is only 0.15 mm. In this case, the nominal for the 1st compression is 0.04-0.075 mm, for the second - 0.03-0.065 mm, and for the oil scraper - 0.02-0.055 mm. Here it is necessary to achieve very high accuracy. The best option is to measure the grooves on the piston and rings. To do this, you can use a micrometer and a set of probes. Measurements on the piston must be made in several places around the circumference.

A few important nuances

The service life of the cylinder-piston group and, in fact, the rings depends on how correctly the thermal gap of the piston rings of a diesel engine or gasoline engine is selected. The appearance of scoring due to the friction of the rings on the cylinder leads to a loss of not only compression, but also geometry. There is little pleasure in this, since grinding will be required to restore the working condition, and in the most neglected cases, boring of the cylinder block.

If there is a radial wear of the rings, the sealing in the combustion chamber deteriorates significantly. This results in poor engine performance and increased engine oil consumption.

What's wrong with a small gap

It would seem that in order to achieve good compression, the gap is as small as possible. In this case, the oil will not burn. All this is only partly true. The fact is that if, during expansion, the gap becomes less than permissible, then a violation of heat transfer will occur. This is partly due to the increased friction of the rings against the cylinder. As a result, scoring appears, wear of the cylinder and ring is accelerated. In the end, the compression rings do not create the proper pressure, and the oil scrapers leave oil on the cylinders. After some time, engine power is lost, lubricant consumption increases and the stability of the internal combustion engine deteriorates.

Summarize

As you can see, it is extremely important to know what piston ring clearance is required for a particular type of engine. Each manufacturer indicates the nominal and permissible values. They are recommended to follow. If during the overhaul the ring is worn out, say by 50%, then it is better to replace it with a new one.

It is not so terrible increased than reduced clearance. Due to the latter, the temperature in the combustion chamber rises, causing mechanical damage to the cylinder. All of this adds up to significant costs. To prevent this from happening, it is necessary to correctly select the piston ring clearance and be guided only by trusted sources. The instructions for the operation and repair of each car contain the data you need, and they should be put into practice.

Recommended:

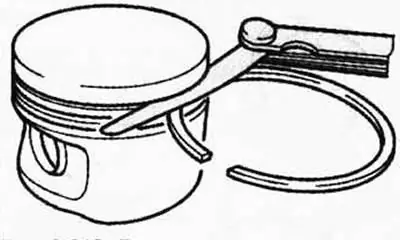

How to put rings on a piston: the technological process of installing and replacing rings

If the car's dynamic performance has deteriorated sharply, oil and fuel consumption has increased, problems with starting have appeared, then this indicates engine wear. But this is not yet a verdict. These symptoms indicate that the rings need to be replaced. Let's see how to put the rings on the piston. The procedure is not difficult, but requires the presence of a tool and care

Starter VAZ-2105: problems and solutions, replacement and repair rules, expert advice

VAZ-2105 is still popular with Russian drivers. It is distinguished by ease of operation and low cost of spare parts. However, if the car owner wants the car to work without problems, he must regularly check it for various faults

The starter turns idling: possible causes, methods for solving the problem and expert advice

Reliability of modern cars has increased significantly compared to the old ones. Therefore, today's drivers do not immediately remember which lever to pull to open the hood. One of the most popular situations that confuse inexperienced car owners is when the starter is idling. It seems to be spinning, but the engine does not start. There can be many reasons for this failure. Let's look at the main ones and find out how to fix them

Adjustment of engine valves 4216 "Gazelle": procedure, work technique, necessary tools and expert advice

Car enthusiasts can do without the services of specialized car repair shops if it is necessary to adjust the valves of the 4216 Gazelle engine. Consider how this is done with your own hands in a garage environment

Space rings: dimensions, drawing, manufacturing, installation. Are o-rings required? How to choose a spacer ring?

If you install discs on other brands, you may encounter such a nuisance as a discrepancy between the disc and the wheel bore. To solve this problem, spacers are used. It is about them that we will discuss in our article