2026 Author: Erin Ralphs | [email protected]. Last modified: 2025-01-22 21:14:09

The principle of the overrunning clutch is to prevent the transmission of torque from the driven element to the drive shaft at the very moment when it begins to rotate more intensively. The product itself belongs to the category of mechanical units. Experts have proven that the clutch is also relevant in cases where you need to quickly transfer torque exclusively in one direction. To properly use the unit, you need to familiarize yourself with the principle of operation, the advantages and disadvantages of the device in advance.

In-demand freewheel device

Experts actively use ratchet and friction units, which have numerous advantages. The principle of operation of the friction type clutch depends on which category the product belongs to:

- With axial closure.

- Universal overrunning wedges.

- With belt mechanisms.

- Multifunctional radial closure.

- Spring mechanism.

Roller overrunning products are the most popular in cars, which favorably differ in a long service life and a high degree of reliability.

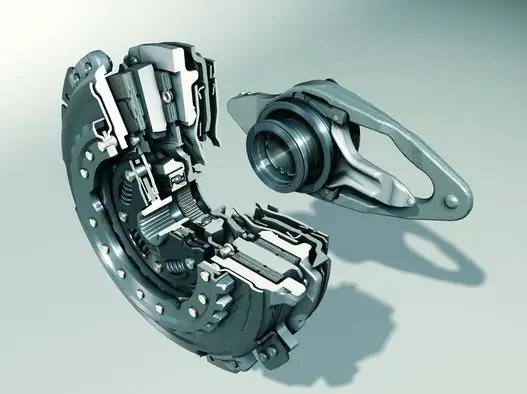

Main structural elements

The principle of operation of the overrunning clutch depends on the performance of all used parts. The design of the unit includes the following critical components:

- Inner clip. This element is securely connected to the anchor - the generator shaft.

- Outer clip. The part engages with the pulley.

- Strong contact plate with built-in gland.

- Two rows of rollers. These structural elements are the connecting parts of the outer and inner cages. The first row consists of needle bearings, and the second row consists of universal profiles that move freely and act as a stopper.

- Durable liner made from polyester.

- Slotted profile.

- Quality beveled bushing.

- Plastic cover.

- Original cylindrical sleeve.

Working principle

Sprag clutch is widely used in the automotive industry. The roller assembly with a free running principle is divided into two main categories: the first is fixed as firmly as possible on the main shaft, but the second is connected to the driven part. During clockwise rotation, the small rollers gradually roll intonarrow gap compartment between two coupling halves. As a result, jamming occurs. That is why it should be noted that the principle of operation of the overrunning clutch is based on the fact that the unit transmits torque in only one direction. If the master rotates the device in the opposite direction, then the unit will simply scroll.

Benefits of using the aggregate

The principle of operation of the overrunning clutch of the generator compares favorably with numerous positive characteristics. Manufacturers note that the product is distinguished by automatic switching on and off, due to which it is not necessary to connect additional control drives. The coupling differs in simplicity of a design. With the help of universal freewheel mechanisms, the designs of critical components and assemblies of equipment are simplified. A freewheel with a ratchet mechanism is more reliable than a unit with rollers. This is due to the fact that the first model is repairable. But the roller device cannot be repaired. During installation, it is strictly forbidden to use percussion instruments, as the corresponding mechanism may simply jam.

Device flaws

The classic starter overrunning principle is not devoid of negative characteristics. Users are not satisfied with the moments that the device cannot be adjusted, there is a strict alignment of the shafts. The main disadvantage of freewheel with ratchetmechanism is that when the pawl engages with the teeth, a blow occurs. Because of this, such a device cannot be used in those units that operate at high speeds. Due to increased loads, the teeth of the ratchet wheel are quickly erased, for this reason the product simply fails. The mechanism rotates with a characteristic noise. It is important to note that today there are devices on sale in which the dog does not touch the wheel when moving clockwise.

Application areas

The universal principle of operation of a bicycle overrunning clutch is in great demand, as it is a universal unit that compares favorably with all analogues in its practicality and durability. Today, freewheel mechanisms are widely in demand in the nodes of cars from different manufacturers. The classic freewheel can be found in the following settings:

- Standard automatic transmission. The freewheel mechanism is part of the multifunctional torque converter. This unit is responsible for the timely transmission and subsequent conversion of torque from the internal combustion engine to the gearbox.

- Internal combustion engine starting systems. In this case, the product is part of the starter. When the engine starts and has gained the required speed, the clutch disengages the starter. Otherwise, the crankshaft could cause serious damage to the starter.

- Toyota's generator overrunning principle is highly valued by experts and ordinary motorists. The device neutralizes vibrations onbelt, while reducing drive noise. The clutch significantly extends the life of the generator.

Common signs of breakdown

Despite the multifunctional principle of operation of the automatic transmission overrunning clutch, this device can also fail under the influence of various adverse factors. According to its design, the product is presented in the form of an improved rolling bearing. In the event of a breakdown, the unit will simply jam. This may indicate that the belt drive that the clutch provides is instantly converted into a conventional one. As a result of this, inertia simply ceases to be compensated, and accelerated belt wear occurs. In order to timely detect a malfunction of the unit, you need to understand exactly what signs may indicate a breakdown. Experts note three main parameters:

- Characteristic tensioner click.

- Belt drive inconsistency.

- Strong whistling noise when engine is on.

When at least one of these signs began to appear, you need to contact a service station. Only a professional can properly diagnose an overrunning clutch. If the unit is broken, then it will have to be replaced, since repair is almost impossible. It is possible to perform all the necessary manipulations on your own in rare cases, since for this you need to have the appropriate skills and devices.

Recommended:

Double clutch: device and principle of operation

Along with the new trends in the development of "green" technologies, the automotive industry is currently experiencing no less interesting changes in terms of approaches to the development of traditional structural parts of the car. This applies not only to the design of the internal combustion engine and the inclusion of more reliable materials, but also to the control mechanics

The principle of operation of the variator. Variator: device and principle of operation

The beginning of the creation of variable programs was laid in the last century. Even then, a Dutch engineer mounted it on a vehicle. After such mechanisms were used on industrial machines

Clutch cylinder VAZ-2107: device, principle of operation, replacement and repair

The use of hydraulic drive in the "seven" is caused by the design features of its clutch. It not only transfers force to the driven disk, but also allows the car to start off smoothly. True, this somewhat complicated the design of the car and its operation. Therefore, it is necessary to know how the VAZ-2107 clutch cylinder is arranged, the principle of its operation and operating features

"Lada-Kalina": ignition switch. Device, principle of operation, installation rules, ignition system, advantages, disadvantages and features of operation

Detailed story about the ignition switch Lada Kalina. General information and some technical characteristics are given. The device of the lock and the most frequent malfunctions are considered. The procedure for replacing with your own hands is described

The principle of the clutch. Car clutch device

Clutch is an integral part of any modern car. It is this node that takes on all the colossal loads and shocks. Particularly high voltage is experienced by devices on cars with a manual transmission. As you already understood, in today's article we will consider the principle of operation of the clutch, its design and purpose