2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:11

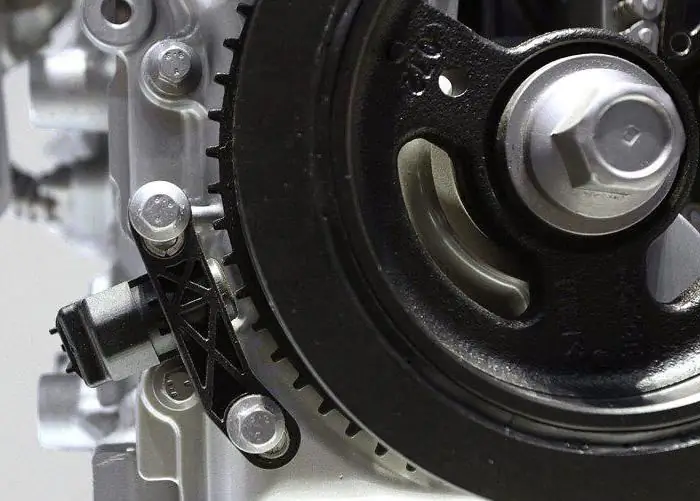

The crankshaft is the central part of not only the engine, but the entire car. The name itself speaks of its form. Now a little about its purpose. In the places of the knees, it has necks on which the connecting rods are fixed with the help of caps drawn with bolts. During the stroke of the piston, the energy that puts pressure on it is transferred to the knee, and, through the lever, rotates the crankshaft around its axis.

The moment that is applied to the crankshaft in order to turn it a full turn is called torque. Engines that have the same displacement and different number of cylinders have different torque, it's not hard to guess which one will have more.

The revolutions of the crankshaft can reach 8 thousand, so the load on it is very high, and the friction force is also high. To facilitate working conditions, as well as reduce the very friction force, a lubrication system is used, moreover, under pressure. We will not touch on it in detail and consider other shafts, we will only say that the system itself is under pressure. In order to reduce wear and delay repair of the crankshaft, liners made ofsofter metal than the crankshaft itself.

A film a few microns thick forms between the bearings and the neck, which serves to lubricate and improve rotational glide.

The main engine failure that may require crankshaft grinding is a drop in pressure in the lubrication system when grooves appear on it. Of course, this may not be the case at all, but, for example, in the oil pump, but this is the most common malfunction.

Before deciding which method to eliminate it, it is worth taking measurements of the necks, both the main ones (they are fixed in the engine block) and the connecting rods (the connecting rods are fixed on them). Two measurements should be made, perpendicular to each other. If the deviation from the nominal size of the neck is more than 0.05 mm, then the crankshaft is ground. Naturally, this is done by professionals using high-precision equipment.

After grinding on the flywheels of the crankshaft, an index of repair size is stuffed, each of which corresponds to a letter, it is for it that liners should be selected. Usually, the crankshaft has three repair sizes that exceed the nominal in increments of 0.25 mm.

But it might not be that hard. If the wear does not exceed the specified, then you can limit yourself to replacing the liners. They can be the same size as the previous ones, or a size larger. The second case is applicable only if the wear of the journals is uniform, without grooves and channels, since it is precisely because of themappearance and pressure drops in the lubrication system.

From the above it is worth making one simple but very important conclusion. The pressure in the lubrication system must be maintained constantly. If it is not there, then the crankshaft will receive heavy wear, it will be overheated, and with it the lower heads of the connecting rods. After they will have to be replaced, and this is already a very expensive repair, incomparable with grinding the necks. In addition, the camshaft of the gas distribution mechanism is lubricated under pressure, or even more than one. If the pressure drops in the entire system, then the camshaft will also not remain without damage, and this is even more expensive.

Recommended:

KAMAZ 740 crankshaft: device and dimensions, repair, replacement

Crankshaft "KAMAZ 740": device, features, photos, operation, dimensions, maintenance. Crankshaft "KAMAZ 740": characteristics, repair, replacement, bearings. Comparative characteristics of the crankshaft "KAMAZ 740" and its analogues

Crankshaft - what is it? Device, purpose, principle of operation

The crankshaft is one of the main elements of the engine. It is part of the crank mechanism. It has a complex device. What is this mechanism? let's consider

What is engine life? What is the engine life of a diesel engine?

Choosing another car, many people are interested in equipment, multimedia system, comfort. The motor resource of the engine is also an important parameter when choosing. What it is? The concept as a whole determines the operating time of the unit until the first overhaul in its life. Often the figure depends on how quickly the crankshaft wears out. But it is written in reference books and encyclopedias

Crankshaft sensor. How to check the crankshaft sensor?

If the car does not start, the engine power drops, malfunctions occur, then the starter, battery or crankshaft sensor may be the cause of this. How to check the last element, many do not know. But the reason may be precisely in it

"Honda", ATV, off-road - what could be dearer to the heart?

The ATV "TRX 680" is a worthy representative of its class. It is worth getting to know him better. Among experienced four-wheeled ATV lovers, the "TRX" series is very popular