2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:12

Probably, every motorist got into such a situation when one fine day, after turning the ignition key, his "iron friend" completely refuses to start. Oddly enough, but the reason for this can be not only a planted battery or a burnt starter, but also a crankshaft sensor. If its body has been deformed or the entire structure has moved a couple of millimeters to the side, this part needs to be replaced.

And when your garage neighbors tell you that replacing this element is a rather complicated operation that requires special expensive tools, do not believe these words. You can change the crankshaft sensor yourself. Moreover, by doing this kind of work, you save a lot of money on service stations and at the same time gain experience in this area. Therefore, today's article will be important for all motorists.

Why does the crankshaft sensor fail?

Based on the readings of this part, the injection system synchronizes the operation of the injectors and ignition. Therefore, injection is not possible without this part. Andwhen the crankshaft sensor stops working, interruptions begin in the engine. Therefore, no modern car can do without this small spare part. And in order to prevent this malfunction, you need to regularly check the condition of the sensor. But when the symptoms began to turn into reality, the driver has no choice but to urgently replace him.

How to remove the crankshaft sensor?

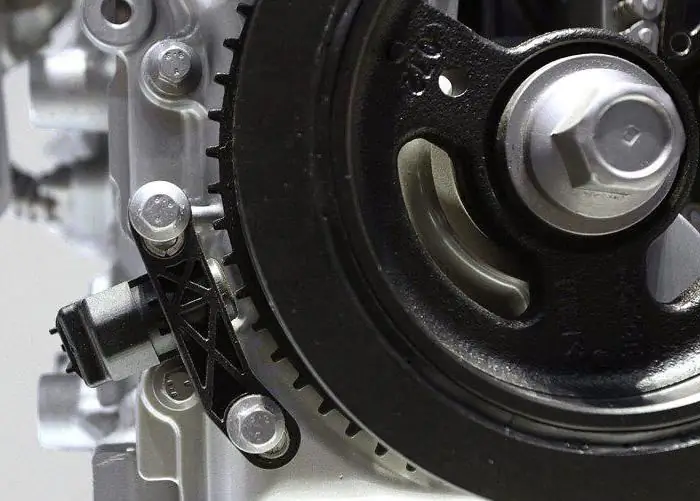

We note right away that this procedure can be performed without a special lift. So, let's get to work. First, unscrew the sensor mounting bolts that connect it to the gearbox. In fact, in order to remove the desired spare part, we need only this stage. But since this part is located in a very inaccessible place (almost on the bottom), we will have to sweat a lot. To work, we need an extension cord, an 11 mm wrench and, of course, good lighting. It is important that the length of the first part is about 80-90 centimeters. If you have these tools, unscrew the bolts. But before you remove the crankshaft sensor, pay special attention to the rubber pad. If in the future it is poorly installed or its gap is at least 1 millimeter, all readings of the measuring device will be inaccurate, and, accordingly, the engine will work intermittently. It is best to mark this detail and put it in a separate place. The entire process of dismantling the part, bolts and spacer should be carried out with great care. This item does not like rough handling.

Next, we take a new crankshaft sensor and mount it in place of the old one. During installation, this element should be lowered through the entire engine compartment so as not to catch the connector from the installed element from above. Then do not forget about the gasket. We mount it carefully and check the integrity of the structure. It is important that the gap between it and the sensor is minimal or completely absent. After that, we attach the wires to the part, connect all the connectors and start the ignition. If you did everything right, be sure - the engine will start with a half turn.

Recommended:

Why is the Check Engine light on? Why does the check engine light come on?

In the age of modern technology, the technical characteristics of a car provide for the presence of a large number of electronics. Cars are literally stuffed with it. Some motorists do not even understand why it is needed or why this or that light is on. In our article we will talk about a small red light bulb called Check Engine. What is it and why does the "Check" light up, let's take a closer look

Why do you need a car? Does it solve the tasks set for today, or does it add new ones?

Since humanity invented the wheel, more and more vehicles have been appearing, for which in some cases this very wheel is no longer even needed. Why do we need a car in our time?

Why does the car twitch while driving? Reasons why the car twitches at idle, when shifting gears, when braking and at low speeds

If the car twitches while driving, it is not only inconvenient to operate it, but also dangerous! How to determine the cause of such a change and avoid an accident? After reading the material, you will begin to understand your "four-wheeled friend" better

How does the crankshaft position sensor interact with other car parts?

Each car, regardless of the year of manufacture and brand, is certainly equipped with such a detail as a crankshaft position sensor, which ensures the smooth and uniform operation of the engine

Crankshaft sensor. How to check the crankshaft sensor?

If the car does not start, the engine power drops, malfunctions occur, then the starter, battery or crankshaft sensor may be the cause of this. How to check the last element, many do not know. But the reason may be precisely in it