2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:12

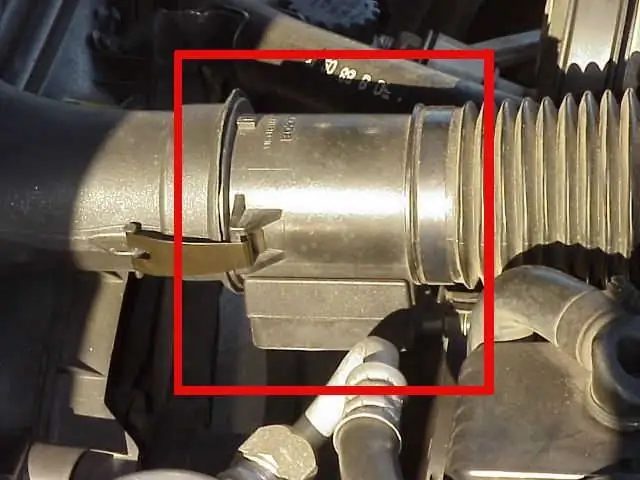

The air flow sensor should detect the amount of air consumed by the engine. Based on the data received from the device, the engine control unit calculates the amount of fuel injected into the cylinders.

Possible "symptoms" of incorrect operation of the flowmeter:

- The engine "does not hold" idle speed.

- Fuel consumption increases.

- The turbine is not connected in time or is not connected at all.

- Engine RPM may be limited to 3,000 rpm.

- Possible speed limit. For example, a car can more or less actively pick up speed up to 100 km / h, after which acceleration stops or becomes extremely slow.

- The machine loses power significantly.

The mass air flow sensor is checked using special equipment - a compressor and an oscilloscope. The airflow is forced to the sensor and the signal range is monitored. It also determines the time during which the heating film on the sensor warms up.

When checking the output signal, the time is measured first,which is occupied by the transient at the moment the ignition is switched on.

In the case when the air flow sensor is working, the value obtained will not exceed a few milliseconds. To increase the warm-up time of the sensor can lead to contaminants that are deposited on the sensing element. In this case, the transient process can take tens and hundreds of milliseconds.

Next, the voltage value is measured with an air flow equal to zero. To check, it is necessary that the engine is stopped, but the ignition must be turned on. The normal value of the output voltage in the presence of zero air flow may be different and depends on which model of air flow sensor is installed.

After that, the maximum value of the voltage is measured during a sharp regassing. In this case, the engine of the machine must be warmed up to operating temperature and the neutral gear must be engaged. During the test, the throttle valve opens abruptly for a time not exceeding a second. This check is only possible for naturally aspirated engines (without compressor and turbine), and if the accelerator pedal is mechanically connected to the throttle valve (using levers or a cable).

When the engine is idle, the air in the intake manifold is very thin. If the air flow sensor is OK, the signal voltage should exceed 4V for a short time. If sensitivethe element is heavily soiled, the sensor may take longer to respond. In this case, the oscillogram is "smoothed out". Due to contamination, the heating current and the sensor signal decrease, which leads to a decrease in fuel supply to the cylinders. Therefore, with a sharp regassing, the voltage of the sensor signal does not have time to reach the maximum values.

If serious malfunctions in the operation of the device have been diagnosed, it should be replaced. The mass air flow sensor cannot be repaired.

Recommended:

Error P0102: troubleshooting the air flow sensor

Modern cars are stuffed with all sorts of electronics. On the one hand, this is good, since having an on-board computer, you can determine most of the faults, on the other hand, frightening inscriptions with fault codes in the operation of the engine often come out. Error P0102 is a common culprit for failures of VAZ family cars. What does this code mean and how to fix it, this article will tell

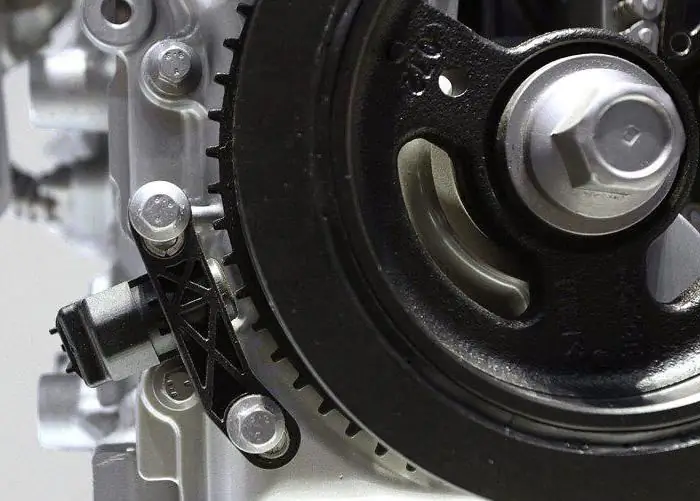

Crankshaft sensor. How to check the crankshaft sensor?

If the car does not start, the engine power drops, malfunctions occur, then the starter, battery or crankshaft sensor may be the cause of this. How to check the last element, many do not know. But the reason may be precisely in it

Air flow meter. Air mass sensor

In order for the engine to work confidently in any mode, it is necessary that it receives the optimal composition of the combustible mixture. The engine is not enough fuel alone, it also needs air

Everything about the DMRV VAZ-2110 (mass air flow sensor)

DMRV VAZ-2110 (mass air flow sensor) is the most important part of a car, without which no modern injection engine can do, including the engine of the domestic "tens". Many car owners at least once faced with the problem of the internal combustion engine. In many cases, the cause of this is a faulty mass air flow sensor. Today we will talk about its design, and also find out if this part can be repaired if it breaks

A symptom of a malfunction of the mass air flow sensor and its diagnosis

The mass air flow sensor (abbreviated as DMRV) is an indispensable device that determines and regulates the supply of the required amount of air to the combustion chamber of the internal combustion engine. Its design necessarily includes a hot-wire anemometer, the main function of which is to measure the costs of the supplied gases. The air flow sensor VAZ-2114 and 2115 is located near the air filter. But regardless of its location, it breaks down the same way, like all modern models of the Volga plant