2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:16

From various books and other sources of information, you can learn that the first wheels appeared about three thousand years before our era. This is evidenced by various images on which the world's first wagons and chariots were drawn.

One of the versions indicates that the first wheels were created in the image of the sun. The wheel circle was considered a divine symbol for some tribes and peoples. The thickness of the wheel rim reached large sizes, because of this, its mass was too large. Accordingly, the speed of transport was quite low. The wheel looked like a wooden disc, which was mounted on the axle and secured with a wedge. The forerunner of the wheel was a wooden roller.

Wheel

The wheels of the first cars were wooden and were no different from the wheels of horse-drawn carts. Then people came up with and created wheels with wooden spokes and a metal rim. Soon, wooden knitting needles were replaced by wire knitting needles, like those of bicycles and motorcycles. Tires were made in the form of flat rubber bands. After a certain period of time, thanks to technological progress,people created pneumatic wheels.

The peculiarity of the car wheel device is that it transmits torque due to the leverage system, and thus sets in motion any vehicle for movement. In today's world, a wheel is made up of two main elements, such as a rubber tire and a metal rim. Nowadays, the device of a car wheel has been simplified and made much stronger and better. Wheels are chambered and tubeless. Tubeless ones don't have a chamber between the disc and the tire. The tire is hermetically sealed to the disc, sitting tightly on the rim. The wheel is an important part of the car, it consists of a rim and a flange.

The rim is one of the parts of the wheel, the tire is put on it. Flange - a disk located in the central part of the rim, with its help the wheel is fixed on the hub of the vehicle axle. The rim is an important part of the wheel.

Car wheels are now available in all global markets. The price depends on the quality of the wheel. There are hundreds of companies producing tires for car wheels. Let's find out why you need a tire.

It is designed to securely grip the wheel and the road surface when driving and cornering, as well as to mitigate impacts; ensures the car's cross-country ability on various roads or off-road. Tires are made from natural or synthetic rubber. A tire without a tube is a tire that consists of a cord, sidewalls and tread. The largest car tires in the world are manufactured by Bridgestone. They are labeled59/80R63, 59" wide, 63" inside radius, 80" outside radius. These tires are mounted on large wheels. Their height reaches four meters. This type of car wheels has a heavy structure. The tire has a tread. The tread is the base layer of rubber that is responsible for the grip of the wheel with the road, and also protects the internal parts of the rubber and the entire wheel from damage when interacting with the road surface. There are universal, road or special. Tires are made to fit all wheel rim sizes.

Tires are classified as follows:

- Chambered and tubeless - according to the structure of the inner surface of the wheel.

- Diagonal - according to the structure of the frame. Diagonal tires - those in which the cross-layers of the court are installed. The angle of their inclination is 35-38 degrees.

- Radical - on such tires, the arrangement of the threads of the court is parallel, at a right angle.

- Universal, seasonal (winter and summer), cross-country ability - according to the width and height of the tread pattern on the tires.

Disks

The disc is one of the parts of the car wheel device. Discs are made from various metals. They consist of the following elements, which we will analyze in more detail. For tuning a car, special sizes of wheel disks are produced. Wheels are measured in inches, for example: 14 inches, 17 inches, 21 inches, and so on.

- Sidewalls.

- Cord.

- Metal frame.

The bead is designed to secure the tire on the rim, as well as toits sealing between the disk. At the heart of the board is a ring made of rubberized steel wire. The bead is a layer of cord wrapped around a ring of wire filling rubber cord. With high strength and rigidity due to the steel ring and solidity, as well as a filler cord, the bead is considered the hardest part on the disc. He is able to withstand strong impacts.

The sidewalls consist of a thin layer of elastic rubber, which is located between the shoulder area and the side. The sidewall is designed to protect the tire tread from mechanical damage and moisture, it is also a continuation of the tread.

Cord is what is inside the rubber. It can be made from metal, glass, polymer threads.

Discs are made of steel, aluminum, magnesium. Steel is used for cheap wheels. Light alloy wheels are made from aluminium. This type of metal is lightweight and inexpensive, resistant to corrosion. The brand of aluminum used is 6061. Its properties are ideal for making wheels.

Magnesium is used to make wheels for racing cars. The discs are strong and light. The manufacture of this type of wheels requires professional equipment, as the processing of magnesium is very difficult due to its reaction to high melting point. Discs are also made from carbon fiber and titanium. These materials make wheels that are light and strong.

Wheel markings

The presence of the inscription P195/55 R15 84 H on the tire means its size and category. Here is the transcript:

- P is the passenger car category and 195 is the tire width in mm.

- 55 is the tire series.

- R - tire design (radical). By the way, the radius has nothing to do with this letter.

- 15 - disc diameter.

- 84 - maximum wheel load (see special tables).

- H - maximum speed (you also need to look at the tables).

The tire manufacturer is also indicated, for example: Hada, Avon, Nitto, the country of manufacture and the mark of the enterprise where this product was made. There are also four digits that indicate the date of manufacture.

Now let's look at the main symbols on the tires:

- MAX LOAD - allowable maximum load in kg.

- TUBE TIRE - Tube tire.

- TUBELESS - tubeless tire.

- MAX PRESSURE - allowable tire pressure in kPa.

- REINFORCED - super-reinforced tire. Has unique properties.

- RADIAL - the width of the radial design.

- REGROOVABLE - maximum depth of the tread pattern when cutting.

- DSI, TWI - location of wear indicators.

- ALL STEEL - the inscription is intended for tires with carcass and steel cord breaker.

- M&S - all season tires. Mud & Show - translates as mud + snow.

- Rotation - indicates that the tire has a direction and an arrow is indicated on it.

- All Season - tires that are used all year round.

- Inside and Outside, as well as Side Facing Inwards and Side Facing Out, are asymmetric tyres. When installed, there are left or right, that is, Left or Right.

- AQUA, WATER, RAIN - indicates that the tires have high protection and stability in rainy weather.

- E - European safety standard.

- DOT - US safety standard

- Traction A, B, C - wet braking capability.

- Treadwear - tire wear resistance (mileage).

- Temperature A, B, C - heat resistance at high speeds.

Note

Marking of car wheels depends on the category of vehicles, country, climatic conditions. Wheel size must be carefully selected. On trucks, several pairs are installed on the rear axles and trailers. Large wheels, small, medium - each type has its own tire size.

Car wheel repair

Often we have to face problems on the roads. One of them is damage to wheel rims and puncture tires. Let's look at how we can deal with this problem.

Repair of wheel rims depends on its type and material of manufacture. How exactly will the wheels be repaired? What technologies will be used and how long will it take? A lot of it depends on the disk itself. When repairing discs, small weights are installed to unbalance. Car wheel repair is quite simple.

Discs are cast, forged and stamped. Alloy wheels are the most common type. For their manufacture, light alloys of metals are used. The result is a strong and lightweight construction, noticeably lighter than steel rims and much more precise. Alloy wheels are lighter than other types, but the allowable imbalance is less than stamped ones. Forged discs are much weaker than cast ones, they are made from rolled carbon steel by stamping. Forged - an even less common type of discs. But they have the advantage over stamped and cast, much stronger and more wear resistant.

When a cast disk is damaged, it is not used for rolling, but for straightening, that is, it is pulled out on special machines. Welding increases the elements lost during damage. The stamped disk is restored by rolling. This allows the structure of the material from which it is made. The disk is much more elastic and can be rolled. Forged wheels are repaired in the same way as cast wheels.

Car wheels receive various damages, which can often be repaired by yourself. But in case of serious damage, it is better to contact a car service, use a tow truck. Car wheels that have cuts and tire bumps are dangerous to drive. If such defects are found, it is better to fix everything immediately.

Tire repair

Let's figure out what a puncture is. This is damage to the tire part in the tread area. Having a tool and a set of special patches, you can fix it in any conditions with your own hands, and then get to the service.

The side cut can only be repaired by vulcanization. This is the most dangerous type of wheel damage. Recommendedhave a spare tire with you.

We seal the puncture with our own hands

Do the following:

- Remove and deflate the wheel

- We take it out of the disk.

- Inspecting the damage site.

- We make sure that the tourniquet or patch that we will supply matches the size of the puncture.

- Clean the surface from dirt and dust.

- Plug a hole, cut or puncture with a tourniquet (you can use two tourniquets).

- Inflating the wheel.

Consider the following type of wheel

Trucks have discless or disc wheels. KAMAZ wheels are equipped with pneumatic tires. The wheels are divided into driven and driven, as well as combined. A truck wheel consists of a rim and a disc. The device of the wheel of a truck-type car is special. The disc has a flat rim. On trucks, two wheels are installed on the rear axle. The disk of the inner wheel is attached to the studs with cap nuts, and the outer wheel is screwed on with conical nuts. The nuts located on the right side have a right-hand thread, the left side has a left-hand thread. The spare wheel on KAMAZ is installed behind the cab. It is supplied by a special hydraulic outlet. Also, non-separable wheels are installed on some types of trucks.

Diskless wheels are used on KAMAZ and MAZ trucks. Currently, they are used for buses and heavy vehicles. They consist of a spoke hub and a rim. These types of wheels are easy to maintain and restore whendamage. On KAMAZ, wheels are selected and installed according to a special category of load capacity.

Wheel hub

The hub is an important part of attaching the wheel to the axle. It is attached through a bearing. The wheel bearing is an important part, since the safety of driving depends on it. A brake drum or disc is also installed on the hub. It provides rotational movement of the wheel.

The bearing is attached to the axle with a thrust washer and nut. By tightening or loosening the nut, we press or loosen the rollers. Thus, adjustment is made to remove the backlash. The wheel bearing is not protected from dirt and dust, therefore it requires constant care and maintenance. The bearing seal becomes unusable, because of this, lubricant begins to flow out of it. This usually happens when the part is heated or exposed to water. And when the stuffing box is worn, dirt, dust, sand gets into the bearing. This causes it to wear out and needs to be replaced.

The front wheel bearing consists of three parts: a cage (outer and inner), a cassette with rollers. When installed, they are lubricated with Litol. This is a lubricant, it is applied inside the bearing. It is not recommended to open the bearing or change the grease in it.

When the bearing is worn, it is replaced by pressing. It is not recommended to knock it out with a hammer. Pressing makes it easy to remove the worn bearing from the seat.

Nuts

The main element of fastening the wheel to the hub are nuts. They are hexagonal in shape and come in a variety of shapes.thread and size. They are made from aluminum, chrome vanadium, steel and titanium.

Aluminum nuts are very expensive. They are made for racing cars. They weigh little, which reduces the extra weight of the wheel. Aluminum nuts are soft and require constant tightening of the wheel. When buying, be sure to specify which nuts fit exactly on your car.

Chrome vanadium nuts cost the same as aluminum nuts. But they are much heavier. The most expensive nuts are titanium, they are used for tuned cars. They are very strong and light and outperform all other products in quality.

Steel nuts are the simplest and most popular nuts. They are the most common type on the world market. They are distinguished by the type of processing: galvanized or chrome-plated. They are affordable.

In closing

Buy only high-quality wheels, the safety of driving depends on them. When one wheel is worn, it is recommended to change a pair.

Recommended:

What is the difference between front-wheel drive and rear-wheel drive: the difference, advantages and disadvantages of each

Among car owners, even today, disputes about what is better and how front-wheel drive differs from rear-wheel drive do not subside. Each gives his own arguments, but does not recognize the evidence of other motorists. And in fact, it is not easy to determine the best type of drive among the two options available

Types of car tinting. Car window tinting: types. Toning: types of films

Everyone knows that different types of tinting make the car more modern and stylish. In particular, dimming the windows in a car is the most popular and popular way of external tuning. The whole advantage of such modernization lies in its simplicity and relatively low cost of the procedure

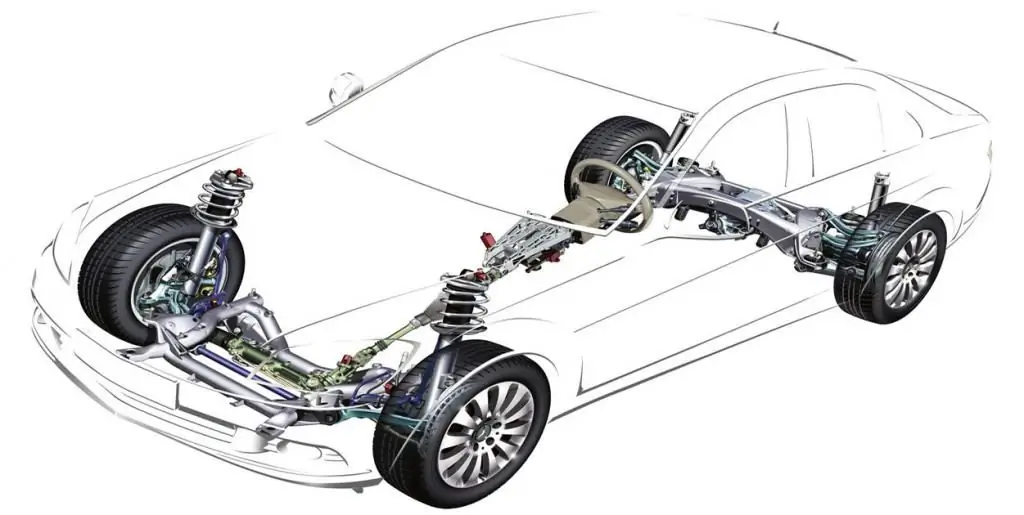

Types of car suspensions: device and diagnostics, features and benefits of various types, reviews

Are many drivers interested in the types of car suspensions? But to know the device of your vehicle, in particular, what parts its chassis consists of, is desirable for certain reasons. This is not only an additional experience, but if necessary, you can take appropriate measures

Adjusting wheel alignment. How to adjust wheel alignment yourself. Wheel alignment stand

Today, any service station offers wheel alignment adjustment. However, car owners can carry out this procedure on their own. So they will learn to better understand and feel their car. Auto mechanics unanimously argue that it is extremely difficult to set up a wheel alignment on your own. Actually it's not like that

Road marking machine for applying road markings: types and description

Road marking machine: description, types, characteristics, features. Road marking machine: overview, operation, photo