2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:11

The brake system of the truck is equipped with an energy accumulator. What it is? This is a responsible and important part of the brake pneumatic systems of trucks. Truckers are familiar with the device and operation of the energy accumulator. Car owners may not even be aware of the existence of such a mechanism.

Description

The energy accumulator (the reader can see a photo of the mechanism in our article) is one of the components in the drive of the parking or auxiliary brake system. Used on buses and trucks. Basically, these are rather large buses and trucks weighing more than eight tons. The energy accumulator is designed to control the operation of the pads due to pressure in the pneumatic system of the working circuit or through a spring when working in parking conditions on the hand brake.

Basic construction

Let's consider the energy storage device. In the vast majority of moderntrucks, you can see the brake chambers. Which are equipped with spring energy accumulators. This is a classic design, developed back in the 50s. This type of power accumulator is considered the most reliable and durable. But the experience of using such devices in harsh conditions has revealed weaknesses - low corrosion resistance, poor protection of the mechanism from moisture and dirt, poor wear resistance of seals. All these factors do not have the best effect on the stability of the units and lead to the failure of the energy accumulator.

The assembly accumulates the energy of a compressed spring, and releases it if necessary. What kind of energy accumulator does the "Wabco" device have? Most often it is installed on the brake chambers and is a body, piston, pusher, screw-axis. The spring has a fairly high power. It can release a force of the order of 2 tons. After that, the piston and the pusher press with this force on the rod in the brake actuator. When compressed air comes out from under the piston of the device (energy accumulator), holding the spring compressed, then the parking brake comes into operation. When it has worked, the air again enters under the pistons.

We continue to study the device of the brake chamber with a spring energy accumulator. The screw axis in this unit is also important. It is required to be able to release the brake manually. Shutdown is carried out by means of spring compression. Sometimes this need for manual shutdown occurs when you need to transport the machine, if in the receiver for some reasonfaulty compressor or engine not running no air.

Operation principle

Let's consider the device of the Kamaz power accumulator in the analysis. When the working brake system is activated, the air compressed by the compressor enters the cavity above the diaphragm. The diaphragm under the action of pressure flexes and acts on the disk, moving the rod. The latter rotates the adjusting lever, which actuates the expanding cam of the brake mechanism.

What is the device and operation of the Kamaz energy accumulator? The rear and middle wheels are braked in the same way as the front wheels. When the driver uses the parking brake, the air that is under the piston of the device (energy accumulator) comes out. The spring is released and the piston moves to the right. Due to the diaphragm, the pusher acts on the rod that moves the adjusting lever.

As a result of all actions, the car can slow down to a complete stop. When the driver releases the parking brake, air is again supplied under the piston. The latter is mixed to the left, the spring is compressed, the rod returns to its original position. Here's how the energy storage works.

Reviews say that if you need to emergency brake the car when it is not possible to use emergency braking, you should unscrew the handbrake screws responsible for these tasks.

Types

These units differ from each other in completeness, type of connection to the brake chamber,specifications.

As for the equipment, regardless of the principle of operation of the energy accumulator, separate devices are distinguished for installation on different types of brake chambers, as well as devices together with a brake chamber.

What is their job? The first type is necessary for the repair of brake chambers, as well as modernization. The component of the second type has already been selected according to the technical characteristics and can be used for repairs without the need for additional assembly and disassembly.

Power accumulators are also divided into two types by connection with the brake chamber. This is a flange connection with one collar and with a bolt, as well as a flange connection with two collars.

Flanges for power accumulators are always used - they say in the reviews. They allow not only to securely fix the components, but also to correctly position them relative to each other. If you use the first type of connection, then the flange is connected to the energy accumulator with bolts and nuts. And with a brake chamber - a collar.

There is an important difference between conventional power accumulators and brake chamber assembly mechanisms. This is the effective area of the membrane, the piston. It is expressed in square inches. Models with an area of 20, 24, 30 square inches are now widely used.

Where is it installed?

The principle of operation of the energy accumulator provides for connection to the brake chamber. On most trucks, it is installed on the brake chambers of the middle and rear drive axles. steering axle datamechanisms do not apply.

Installation

On a truck, the brake chamber and the spring energy accumulator connected to it are mounted on the brackets of the expanding knuckles. Fastening is carried out with two nuts screwed onto the bolts of the chambers. The installation area must provide enough space to connect the compressed air hoses and pipes. In general, installing a power bank is a relatively easy process.

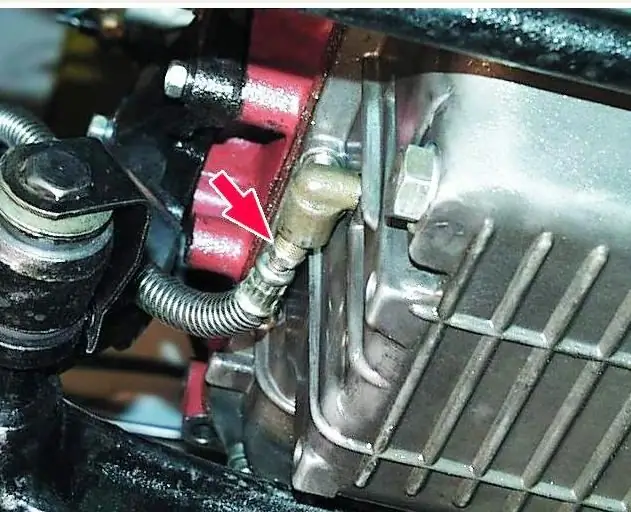

First, you need to dismantle the brake chambers and connect them to the power accumulators. Hoses for air in the cavity above the diaphragm are connected to the appropriate fittings. Next, install and power the receiver. From it, air is supplied to the accelerating valve and to the parking brake lever. Next, the tube goes to the relay valve in the upper part.

Then you just need to supply air to the top of the energy storage - where the springs are installed. If you need to replace the energy storage, you can use this quick guide.

Assembly recommendations

Truck brake specialists give advice on assembling these units. First of all, the assembly must be carried out very carefully - chips or abrasive dust, dirt and other substances should not get inside the mechanism. You also need to remember what is written on the flange - the spring is in tension.

When assembling, all parts of the mechanism that rub should be lubricated with a thin layer. When assembling rubber elementsit is important to be very careful - they are very easy to damage.

If the rubber products are defective, the element must be replaced. Connecting the camera must be carried out strictly according to the instructions for the car. The release screw must be fully tightened. After assembly and installation, you need to supply and bleed air into the system at least three times.

The same recommendations should be followed when dismantling the unit. How to remove an energy accumulator on a MAZ car? The device is dismantled in the reverse order. You need to remove the brake chamber, and then unscrew the nuts of the flange connection.

Selection of aggregates

The market for spare parts for trucks offers a fairly large selection. It is possible to single out devices with different parameters, units for trailers with SAF, ROR, BPW axles. There is also a wide range of energy storage devices for semi-trailers with disc and drum brakes. The energy accumulator and brake chambers can be installed both on imported models and on domestic KamAZ and MAZ trucks, although this is not always worth doing - reviews say. The car must be equipped only with spare parts intended for a specific model. Otherwise, it is impossible to guarantee the high-quality and stable operation of such a mechanism.

Recommended:

Seasonal motorcycle storage: storage rules and useful tips

Winter storage of a motorcycle is a topic on which a huge number of articles have been written, a lot of videos have been shot. Who would have thought that most of these tips are just advertising. Therefore, this article will provide refutation of popular recommendations for storing a motorcycle in winter

Oil cooler "Gazelle" - description, device, diagram and reviews

Everyone knows that the cooling system is a very important element in any car. Usually, it means a liquid engine cooling system. But I must say that in modern machines there are a number of other systems. What applies to them? This can be transmission fluid cooling (if the car is equipped with automatic transmission), or engine oil. We will talk about the last system today, using the example of a commercial GAZelle car

Additional automatic transmission cooling radiator: description, device, diagram and reviews

Automatic transmissions are no longer a rarity, and besides, they must be handled with care, since the oil that is present in the gearbox mechanism can overheat. And then it leads to very sad consequences. To avoid this, it is worth installing an additional automatic transmission cooling radiator and not knowing grief

Non-adjustable hubs on the Chevrolet Niva: overview, diagram, device and reviews

Put an unregulated hub on the "Niva": is it difficult? By yourself or in a service? In this article, we understand

Carburetor and injector: difference, similarities, advantages and disadvantages of carburetor and injection engines, principle of operation and expert reviews

For more than a hundred years, the car has firmly established itself in our lives. During this time, managed to become a familiar, everyday means of transportation. Let's see what the difference is between a carburetor and an injector, what advantages and disadvantages they have