2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:12

Many modern cars are equipped with disc brakes both front and rear. But they also produce cars that use rear brake drums. This mechanism has been used in the automotive industry for over a hundred years. Like many other elements, such a brake system can wear out, and then it is necessary to dismantle and replace these parts.

Design

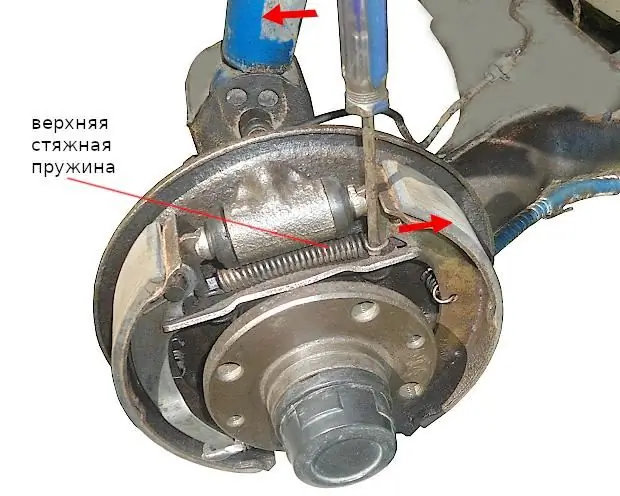

The rear brake drum consists of several parts. This is a rotating drum and brake pads. In the process of braking, the latter rub against the surface of the hollow drum inside. In order for the pads to move, there are special springs in the design. They compress or decompress depending on whether the driver presses or releases the brake pedal.

The brake cylinder is responsible for the operation of the pads - it presses the pad against the surface of the drum under the pressure of the working fluid. There may be several of these cylinders. The whole mechanism is mounted on a stamped brakeshield.

The rear brake drum may have another design - tape. Here, braking is carried out by a flexible metal tape, which is stretched and compresses the drum. The automotive industry has long abandoned this system.

Drum Brake Solution Benefits

One of the main advantages of these mechanisms is that they are securely closed from any environmental influences. This brake system is ideal for use in heavy or even extreme conditions.

Dust and moisture practically do not get into the pads, which significantly increases the life of parts. This system also generates less heat during braking, which makes it possible to use cheaper entry-level fluids with a low boiling point.

Another advantage is that the braking force can be increased not only by the larger diameter of the brake drum, but also by its width. Thus, the contact patch of the pad with the surface of the element becomes larger, which can significantly improve the braking properties.

Rear brake drums can improve work efficiency due to their design. The drum rotates and in the process of braking it constantly wants to take the pads behind it, as if turning them. As a result, pedal effort is reduced.

Design cons

For all its merits, such a brake system has a low response speed, unlike disc counterparts. There are also certain difficulties in setting up, the design haslow stability. When the rear brake drum heats up, it happens that the pads “stick” and the braking performance deteriorates significantly.

When the air temperature is too low, it is not recommended to use the handbrake. There are many situations when the pads simply freeze to the drum. Because of these troubles, in most modern expensive cars, they prefer to leave this mechanism.

Rear brake drums are more often seen on budget models, on urban subcompacts, where they are installed at the rear. Also, this system is installed on trucks.

Faults: signs and causes

Since the rear wheels participate in the braking process much less than the front ones, the car owner will not immediately be able to understand that their efficiency has decreased. In addition, the decrease in this very efficiency is gradual and slow.

Drum brake problems can be felt when braking vigorously - the car stops much more slowly than usual. On most machines, the breakdown of this system is especially noticeable when it is necessary to move in reverse. The front brake system, which has become a rear one, does not want to work alone and stops the car inefficiently.

Brake fluid leaks can lead to shutdowns of one or two circuits of the brake system - this causes a decrease in braking efficiency by 30-60%. The air in the hydraulic drive leads to a soft feel when the pedal is depressed. A brakeonly triggers at the end of the turn.

If the pads are warped in the drum, the springs or struts are broken, the driver may hear scraping sounds. This can cause jamming and overheating of the drum. It can also lead to reduced machine overrun or high fuel consumption. Among the problems, there is also an ovality of the drum.

Varieties of malfunctions

Among the most common reasons why rear brake drums lose efficiency is not a decrease in pad life, but increased wear on the drum itself. Inside, on its working surface, the circumference of this very surface increases. When the pads and the working surface are worn out at the same time, there is a risk that the pistons will be squeezed out of the working cylinder, the wheels will jam or the brake fluid will leak from the circuit.

On high mileage vehicles, springs can loosen, “stick” or break due to corrosion. The force of pressing can be noticeably reduced due to the weakening of the handbrake cable. Rarely, but there is a detachment of the friction lining from the shoe. In this case, it is recommended to replace the rear drum brake pads.

Fault diagnosis

If there are traces of liquid on the surface of the working cylinder, this indicates that air has entered the system. For accurate diagnosis, you need to go to the service station, where there is a special stand that allows you to calculate the effectiveness of each mechanism.

In order for drum brakes to work properly, they must betimely service, check their work. To do this, it is enough to stop abruptly from a speed of 60-80 km / h. These tests need to be done multiple times.

Remove the rear brake drum: when needed

The drum is subject to replacement if it is deformed or its surface has through cracks and dents. In addition to the deformation of this mechanism, there may be a working surface on its working surface (the inner diameter of the element increases). The rear brake drum (VAZ 2101-2107) has a diameter of 200 mm. If the size exceeds 201.5 mm, then the part must be replaced.

Replacing the brake drum VAZ 2101-07

The replacement process must be carried out with the machine suspended, with the handbrake released. The first step is to remove the wheel from the side where the drum will be dismantled.

Next, using a wrench or spanner wrench, unscrew the guide pins that hold the drum and attach to the wheel hub. When they are turned away, you should pull the drum housing - it should come off.

If the rear brake drum (including VAZ-2107) is not removed, which is very often the case, then it is necessary to wrap two M8 bolts into the holes that they will screw in. They need to be rolled evenly. As a result, the part can be removed.

VAZ 2108-099

To remove the rear brake drums of VAZ models 2108-099, you need to turn on the first gear, and also install stop bars under the two front wheels of the car. It is important that the handbrake lever is released. Then the wheels of the car are removed, and the brake mechanism is cleaned of dirt.

After cleaning, unscrew the two mounting pins, apply a little WD-40 to the wheel hub and clean off the dirt and corrosion. Using a rubber or polymer hammer, pull the drum off the hub with light blows. If the part does not want to give in, then using pins or M8 bolts, you can compress the drum.

VAZ-2110

The rear brake drum VAZ-2110 can cause problems for the owner in the process of replacement or removal. The part is dismantled quite simply, provided that the car is new. On older cars, the removal process entails problems. To work, you will need a powerful hammer, a 7 mm deep head, and a ratchet. First of all, the bolts holding the rear wheel break off. After the car is jacked up, they are finally turned away and the wheel is completely removed.

Now unscrew the pins on the drum. This is best done while the car is still on its wheels. You can also apply the handbrake. Then, on the reverse side, the drum is knocked off the wheel hub with a hammer. If it doesn’t come out, then the studs will help - they are screwed from the corresponding hole and when they are evenly twisted, the drum is dismantled.

In the same way, the rear brake drum (Nexia) is removed on Korean cars. In some cases, it is necessary to apply force, but most often after processing with WD-40, the contact point of the drum is perfectly removed.

Renault Logan

If with VAZ cars brute force was used to dismantle the brake elements, then in the case of Logan, a different method is used. First of all, the first gear is turned on at the checkpoint. Then the wheel chocks are placed under the two front wheels. Next, the decorative caps are dismantled, if they are on wheels. When the caps are removed, carefully knock out the protective cap from the hub and remove it.

After loosen the wheel bolts and the hub nut. In this case, the machine must be on the ground. Then raise the back of the car and remove the wheel. Now you can unscrew the hub nut to the end - when installing a new drum, you should also purchase a new nut.

The rear brake drum is removed from the coupling pin (Logan Dacia is no exception), and with it the bearing. In these vehicles, the mechanism is integral with the hub.

The second part is removed in the same way. If an old drum is being installed, it is necessary to grind off the shoulder on its working surface. It is also necessary to bring the gap adjuster mechanism into working position and bring the brake pads together with mounting blades.

When installing, the Renault Logan rear brake drums must be tightened with a hub nut with a force of 175 Nm. After installation, it is necessary to adjust the clearances by depressing the brake pedal several times. Clicks will be heard during the process - when the gap is adjusted, they will stop.

This is how the dismantling is donedrum brake for service or replacement. As you can see, you can do this process yourself, saving money on service stations.

Recommended:

Do-it-yourself replacement of the rear brake pads on the VAZ-2109

Stop any machine is due to friction. It occurs between the pads and the metal surface of the disc or drum. On VAZ cars of the Samara series, disc brakes were installed on the front axle, and drum brakes on the rear axle. The latter have a high service life due to the fact that they account for about 30% of the total load when the car stops. But still they need to be constantly checked and changed

Chevrolet Niva catalyst: specifications, signs of malfunction, replacement methods and removal tips

The exhaust system is present on all cars without exception. It is a whole complex of parts and devices through which exhaust gases pass. If we talk about the Chevrolet Niva, this is a resonator, catalyst, oxygen sensor, exhaust manifold and muffler. In most cases, the task of each element is to reduce the noise or temperature of the exhaust gases. But today we will talk about such a detail, which also purifies gases from harmful metals

Where and how to pierce brake discs? Grooving of brake discs without removal

The brake system of a car requires regular maintenance. In particular, this applies to replacing brake pads, inspecting discs for defects, changing fluid, etc. But far from always this is done on time and is done at all. Many turn to the service station only in case of obvious malfunctions. But all this can be avoided if you change the pads in a timely manner and do not forget to grind the brake discs

Rear brake disc replacement and repair

Brake discs are the most important part in the system of any car. The condition of this part depends on the safety of the driver, passengers and other road users. If one of the discs is worn out, this is a direct safety hazard on the road. Often the front discs experience higher loads, but this does not mean that the rear brake disc is not a critical part. This element requires maintenance, replacement and repair in the same way as the front

EGR removal: software shutdown, valve removal, chip tuning firmware and consequences

While European courts are noisily and scandalously dealing with European engineers who do not make cars environmentally friendly enough, domestic car owners queue up at service stations to turn off or remove the exhaust gas recirculation system. What is the USR, why does the system fail and how is the USR removed? All these questions will be considered in detail in our today's article