2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:16

Knocking is a phenomenon in which the air-fuel mixture ignites spontaneously. At the same time, the crankshaft of the engine continues to rotate, experiencing enormous loads. To get rid of it, it is necessary to timely correct the moment of fuel injection, ignition. In modern injection cars, electronic control systems based on microcontrollers are used. They allow you to take a lot of characteristics and control the operation of all components and assemblies.

Detonation sensor device

Any knock sensors (VAZ, GAZ, foreign cars) use a piezoelectric element. The bottom line is that when exposed to this element, a signal is generated. And the greater the load, the stronger the signal level. Detonation is basically a knock. Therefore, if you hit something on the sensor body, it will generate a signal of a certain magnitude. The following types of sensors are used on modern internal combustion engines:

- Broadband (with two contacts).

- Resonant (with one contact).

It is these features that distinguish the two types of devices.

How the sensor works

The VAZ knock sensor, regardless of its type, is located between the second and third cylinders of the engine - this is where the middle of the block is located. Therefore, the device equally detects detonation in the first and fourth cylinders (the distance from them to the sensor is the same). Detonation is a phenomenon that can damage pistons, rings, fingers, valves. And with prolonged exposure, the engine will simply fail.

When the sensor detects knocking, it sends a corresponding signal to the electronic control unit. The latter analyzes the signal level and corrects the ignition timing, fuel injection timing, etc. These characteristics also depend on the quality of the fuel mixture (this parameter is controlled by an oxygen sensor).

Varieties of sensors

In the first years of production, exclusively resonant ones were installed on Lada injection cars. The peculiarity of single-contact sensors is that they are able to catch only the knocks of the detonation frequency. But broadband devices perceive all the noise bands, after which it emits detonation ones. Both types of devices work differently, just replacing one with the other will not work. Even if you change the wiring (because the number of pins is different), this will not solve the problem. And if you decide to install a wideband sensor, you will have to change the electronic control unit designed to work with it.

Product cost

On sale you can find many products from different manufacturers. And if there isThe knock sensor is faulty and needs to be replaced. The cost of some is very high, but cheap devices can also be used for domestic cars. Resonant knock sensors manufactured by General Motors will cost about 2500-2700 rubles.

Not cheap, but broadband devices of the domestic manufacturer AvtoPribor cost 250-350 rubles, and StartVolt is about half the price - about 200 rubles. The price of the electronic control unit in the secondary market is 2000-3000 rubles. Therefore, it will be much easier to remake the entire system to use cheap broadband sensors than to install imported single-contact ones.

Main symptoms of broken knock sensors

If we talk about domestically produced VAZ cars, then knock sensor malfunctions appear as follows:

- A lamp on the dashboard lights up, signaling the presence of a breakdown in the engine systems.

- A noticeable deterioration in vehicle dynamics, there is a lack of power.

- If you press the gas pedal sharply, a knock will appear, signaling detonation.

- Increase in engine operating temperature. The piezo element does not work, as a result of which the electronic control unit sets the incorrect ignition timing.

The most common causes of detonation are low-quality gasoline and engine overheating. But at the same time, the sensor should work and givethe corresponding signal to the ECU, which will correct the angle and allow you to get rid of the knock.

Engine error codes

In the event that there are symptoms of a DD failure and the Check Engine lamp starts to burn, check the engine with a scanner. Signs of detonation usually appear with the following errors:

- P0326 - high signal from the sensor.

- P0327 - sensor signal too low.

- P0325 - broken wiring to knock sensor.

Please note that error 0327 can signal not only a failed knock sensor, but also that there is a poor-quality contact in its connection circuit. Check all connections, clean if necessary and treat with penetrating grease. Oxidized contacts are a very common cause of this error. The main reasons why the code 0327 appears:

- Instrument malfunction.

- No power or control signal to the knock sensor connection block.

- There is rust in the area where the body of the instrument is attached to the engine block.

If the case is rusted or oxidized, it can be cleaned with sandpaper. But if there is a lot of pollution, it is easier to replace the device - the cost of a broadband device is small.

Diagnosis

At the point where the knock sensor is located, the level of knocks of the same magnitude will cause an equal impact on the engine block. Therefore, DD will generate a signal of the same level. To checkoperability of the device, it is necessary:

- Set the multimeter to voltage measurement mode (0.2 V).

- Connect the contacts of the device with the probes of the multimeter.

- Gently apply a few blows to the body of the sensor - this way you can simulate detonation knocks.

- Look at the multimeter readings - they should change.

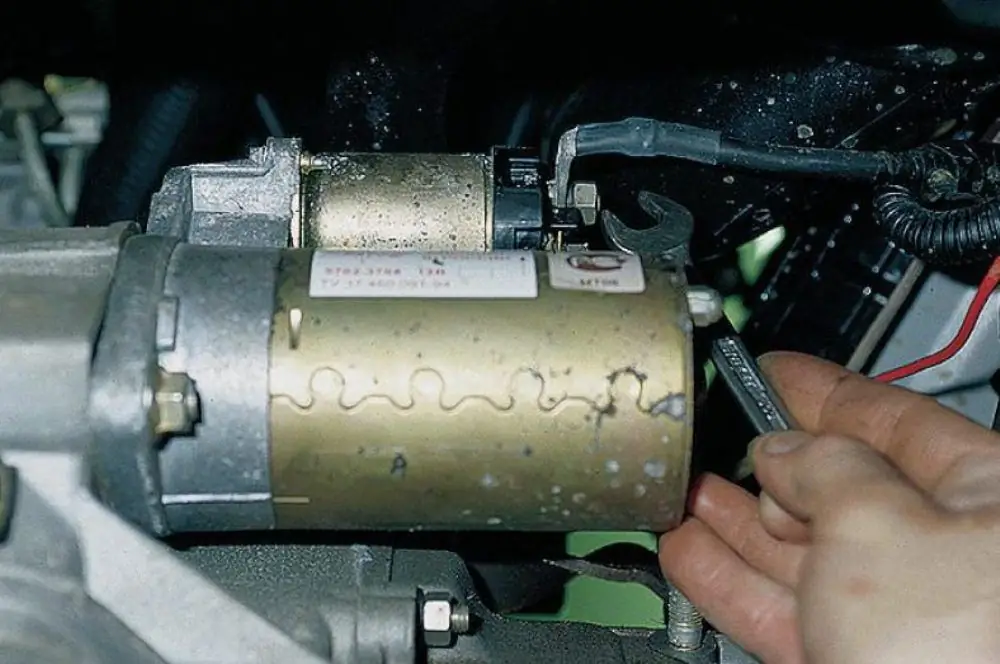

Detonation is a knock, and a short one at that. Therefore, it is advisable to use not a digital multimeter for diagnostics, but a pointer one - it will show the operation of the device much more clearly. To replace the sensor, you will need to disconnect the old one from the block, unscrew the fastening nut and remove the old one. A new one is installed in its place and the nut is tightened. Having connected the block of wires, it is necessary to check the operability of the system.

Recommended:

Where is the VAZ-2112 starter relay located? Location, purpose, replacement and device

The starter relay on the VAZ-2112 performs an important function on any car, regardless of model. Failure of this device leads to the fact that the car will not start. Drivers who are engaged in self-repair of the vehicle need to know where this unit is located and how to fix it if any malfunction occurs

Idle speed sensor on the VAZ-2109 (injector): where is it located, purpose, possible malfunctions and repairs

In injection cars, a power system is used that is different from the carburetor with its channel for idling the engine. To support the operation of the engine in XX mode, an idle speed sensor, the VAZ-2109 injector, is used. Experts call it differently: XX sensor or XX regulator. This device practically does not cause problems to the car owner, but sometimes it still fails

Rough road sensor: what is it for, where is it located, the principle of operation

What is the rough road sensor for and how does it work? Everything you need to know about this device: purpose, principle of operation, possible malfunctions, features of diagnostics and replacement, as well as recommendations

Where is the oxygen sensor located? How to test an oxygen sensor?

Often this device fails. Let's look at where the oxygen sensor is located in the car, how to check its performance. We will also find out the signs of a malfunction and everything about this sensor

Knock sensor. Principle of operation and verification

Modern cars are equipped with various sensors, based on the readings of which the control unit regulates the operation of the entire unit. One of these elements involved in the fuel injection system is the knock sensor, the principle of operation of which is based on the piezoelectric effect