2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:18

The G-222 generator is used on most domestic cars. It is capable of delivering a maximum current of 55 amperes at a voltage of 13 volts and 5000 rpm. The gear ratio between the engine crankshaft and the generator pulley is 1 to 2.04. In this case, the rotor can rotate at a maximum speed of 13,000 rpm. Voltage adjustment is made in the range from 13.6 to 14.6 Volts.

Design features

On VAZ-2105 cars and other models, a generator is needed to power the power supply system when the engine is running. It also charges the battery. Almost until the end of the eighties, a G-222 generator was installed on all cars.

Starting from the VAZ-2108 model, generators 37.3701 were installed. Its design is absolutely the same as that of the G-222 generator, the characteristics differ quite a bit. There are differences in the winding data of the stator and rotor, a slightly different type of voltage and current regulator of the rectifier. Later, 37.3701 began to be installed on VAZ-2105 cars.

Where is the generator installed?

If you look closely, it turns out thatthe car alternator generates three-phase voltage. These are synchronous electrical machines, the excitation of the windings is carried out using an electromagnet. To convert alternating current to direct current, a rectifier is installed at the rear of the generator, which consists of silicon diodes. Thanks to this connection scheme, it turns out to convert a three-phase alternating voltage into a constant unipolar one.

The generator set is mounted near the engine block, on the right side. The torque from the crankshaft pulley is transmitted using a V-belt. There are eyelets on the covers of the generator set, with the help of which the device is fixed on the brackets. Rubber bushings are installed inside these lugs, they allow you to save them from damage when overtightened. From above, the G-222 generator, the connection diagram of which is shown in the photo in the article, is attached to the tension bar with a stud and nut.

The main components of the generator

There are four main elements that make up the G-222 generator:

- Mobile rotor with excitation winding.

- The stator is the fixed part in which the electric current is generated.

- Front and back covers, they are made of aluminum alloy. Thanks to this, they are very light in weight, and most importantly, they are perfectly cooled.

- Rotor is a shaft with a corrugated surface. It has beak-shaped steel poles pressed into it. Together with the core, the shaft forms an electromagnet. Inside the beak-shaped poles is a plastic frame on which there is an excitation winding. The ends of the windings are connected to slip rings on the rear side of the rotor. These rings are mounted on a plastic sleeve.

Rotor bearings

To facilitate the rotation of the rotor, bearings are installed in the front and rear covers. They are of a closed type, the lubricant is incorporated directly during the manufacture of the device. When operation takes place, there is no need to additionally lay lubricants there. In the event of a malfunction of the G-222 generator associated with bearings, it is necessary to replace the rollers, they cannot be repaired.

The inside of the rear bearing is pressed directly onto the rotor shaft. With the help of a rubber ring, the outer part of the bearing is clamped. The inner part of the bearing located in the front cover is freely mounted on the rotor. There is also a distance ring. The outer cage is clamped with two washers fixed with four bolts.

A pulley and a fan are installed in front of the rotor shaft with a keyed connection, which cools the rectifier unit and the inside of the generator. The air flow enters the windows located in the front cover, freely passes through the stator and rotor, after which, cooling the rectifier unit, breaks out.

Generator stator

Electrotechnical steel is used to make the stator. Many plates are connected withelectric welding. From the inside, there are 36 slots in the stator. They are insulated with varnish or cardboard. Three windings fit tightly into these bases, which allow you to generate three-phase voltage.

To prevent these windings from falling out, they are fixed with plastic tubes or wooden wedges. One winding contains six coils. All three windings are connected according to the "star" scheme. In other words, one end of each of them is connected to the body of the G-222 generator. Repair of the stator winding is impractical, it is much easier to replace it completely.

The following components are located in the back cover:

- Semiconductor rectifier unit.

- Voltage regulator and brush holder in one package.

- Capacitor.

- Bearing.

- Power contacts.

Rectifier unit

There is a rectifier unit on the back cover. It is assembled according to the bridge circuit, contains six power semiconductor diodes. If you diagnose these devices, you need to know that they pass electric current in only one direction. Diodes are located on special aluminum holders. To simplify fastening, half of the semiconductors are connected to one part of the horseshoe plate, the others to the second.

Negative semiconductors, which are available in the circuit of the rectifier unit, are installed in a special holder. The positives are connected to terminal "36" of the generator set. Due to the fact that the diodes are firmly installed in their respective holders, efficient cooling is ensured. The rectifier unit is fixed to the cover with three bolts.

Positive diodes, insulated with plastic bushings, are also securely fixed in the aluminum plate. The nuts on the bolts for attaching the plates to the back cover simultaneously clamp not only the terminals of the semiconductors, but also the windings. The negative terminal of the generator is its body. Positive is contact "30" installed on the back cover.

Voltage regulator

Thanks to this device, the optimal voltage value is maintained at the output of the stator windings, regardless of the frequency with which the rotor rotates. Moreover, the voltage value will be kept in the range of 13.6-14.6 Volts, regardless of what load affects the engine and the power supply system. The generator G-222, whose device is the same as that of its successor 37.3701, has a small-sized voltage regulator.

Structurally, the relay-regulator and brush holder are made in one housing. The brushes, which are pressed against the slip rings on the rotor, supply voltage to the excitation winding. One brush is connected to the "B" contact of the voltage regulator, the second to the "Sh" terminal.

If there were no regulator

In the event that this device did not exist, the voltage at the generator output could vary in a huge range - from 9 V to 25-30 V. Of course, this would immediately disable all consumerselectricity. The main conditions for the operation of any generator are the presence of a constant magnetic field, and a mobile one. It is the regulator that allows you to create a constant field. To correct the voltage at the output of the installation, less powerful additional diodes are installed in the rectifier unit. With their help, you can slightly increase the output voltage.

How does a generator set work?

After the ignition is turned on, a relay is activated that supplies voltage from the positive terminal of the battery to the regulator. In this case, the voltage regulator goes into the open state, supplies current to the excitation winding of the rotor. Power from the plus of the battery is supplied to the regulator, through the excitation winding, to ground, that is, the negative terminal of the battery.

In this case, a magnetic field is created around the rotor, and it is constant. As soon as the crankshaft starts to rotate, the rotor of the generator set also spins. At the same time, the north pole, then the south, passes under the stator teeth. The magnetic field moves, as a result of which an electric current is generated on the stator windings. After that, the alternating voltage, which is removed from the three terminals of the stator winding, is supplied to the rectifier unit.

In the event that the rotor speed increases, the voltage at the generator output exceeds the value of 14.6 Volts, the regulator goes into a closed state. In this case, no current is supplied to the excitation winding. And then the voltage at the output of the generator sharply decreases, after which the regulatoropens. The number of transitions to the open and closed state can be up to 250 times in one second. And at the output of the generator set, voltage changes are imperceptible. In order to smooth out the ripples of the electric current as much as possible, and most importantly, to get rid of the variable component, an electrolytic capacitor is installed.

How to disassemble the generator?

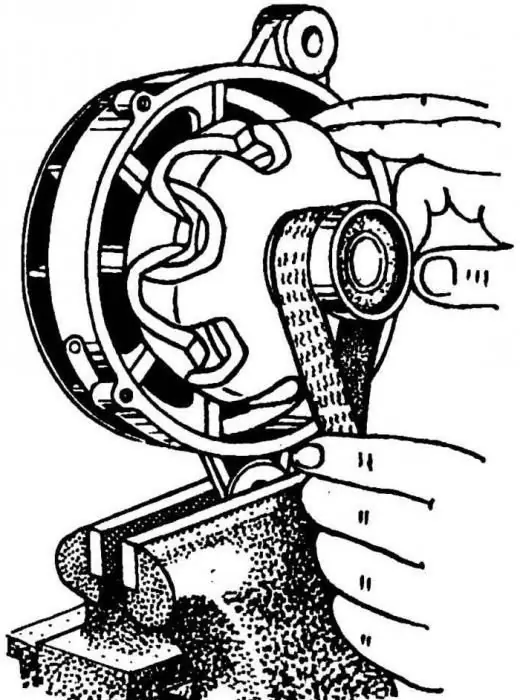

To disassemble the generator, you must first remove it. To do this, unscrew the nut located on the top bar. A bolt is unscrewed from below, which is used to fasten to the engine block. It is advisable to clean and purge the device before starting disassembly. Then you can unscrew the nut with which the pulley is attached. Next steps:

- It is necessary to dismantle the pulley with a puller, carefully remove the key and washer.

- Now we need to disable the regulator output. The voltage regulator is attached to the back of the generator with two bolts. Screw them out.

- Carefully remove the device along with the brush holder. Then disconnect the capacitor.

- Next, it is necessary to unscrew the nuts that fastened the covers of the generator set. Unscrew the screws that connect the leads of the diodes and the stator windings.

- Remove the nut on the terminal.

- Remove the rectifier unit.

After that, you can completely remove the rotor and start diagnosing all the components of the generator. The differences between the G-221 generators and the G-222 are insignificant, so you can disassemble according to the aboveinstructions.

Recommended:

Battery indicator: principle of operation, connection diagram, device

The reliability of starting the car engine depends on the degree of charge of the battery. Hence the need to constantly monitor the battery charge level. The article will introduce readers to devices that allow you to constantly monitor this important battery parameter, the principles of their operation. The material provides brief recommendations for user actions to be followed in various states of the display elements

UAZ generator: connection and replacement

UAZ cars are perhaps the most common SUVs in our country. The highest maintainability, simplicity of design, reliability - all these factors contribute to their popularity for many decades. Unfortunately, mechanics, no matter how reliable it may be, is still not eternal. Including electrical appliances. There are many failures in their work, but the most critical element is the electric current generator. About him and will be discussed today

Window regulators VAZ-2114: connection diagram. Power window button pinout

VAZ-2114 - a car in which a power window malfunction is a common occurrence. This is one of those troubles that does not interfere with driving, but pretty much spoils the nervous system of a motorist. The inability to ventilate the air in the cabin, reduce the temperature in summer often reduces the composure that is so necessary for a person behind the wheel

Generator VAZ 2108: installation, connection, diagram

What is a VAZ 2108 generator and where is it installed, every owner of this car knows. But it is unlikely that everyone will be able to say on what principles it works, as well as list all the main elements of which it consists

Gazelle generator and its malfunctions. Installation of the generator on the "Gazelle". How to replace the generator with a Gazelle?

The electrical equipment of this car is made according to a single-wire scheme: the negative terminals of the instruments and equipment are connected to the "mass" - the body and other mechanisms of the car, which play the role of a second drive. The on-board network of the Gazelle is equal to the nominal voltage of 12V DC. To turn on the electrical circuit, the ignition switch is used, which consists of a contact drive and an anti-theft lock