2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:18

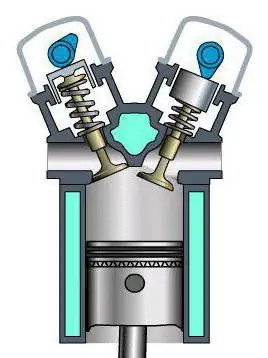

Every year the proportion of cars with diesel engines is increasing. And if earlier such motors were associated with commercial vehicles, now tractor engines can often be seen on small cars. Such a high popularity of diesel cars is due to low fuel consumption and high torque. Due to the turbine, the power of such cars is no less than that of gasoline ones, and the consumption is one and a half to two times lower. But you need to understand that diesel is a completely different philosophy. These internal combustion engines have their own differences and repair features. In today's article, we will analyze a fairly common problem - air leakage in the diesel fuel system.

Symptoms

Usually, in this situation, the engine starts well on a cold one, but further workraises questions at idle. Typical symptoms include:

- Shaking and tripling of the power unit.

- Slow throttle response.

If the problem is ignored further, a long and difficult start of the internal combustion engine is possible. Sometimes the situation comes to the point that starting the car becomes completely impossible. There is too much oxygen in the system for the mixture to ignite properly.

Reasons for suction

There are many reasons for this problem. This is:

- Rotted clamps and cracked fuel hoses. This is the most common reason for the appearance of air in the return of the diesel fuel system. This problem is especially relevant for owners of cars with plastic hoses. Unlike brass, they have quick releases. Of course, replacing such a hose is much easier. However, it is the quick releases that are the most fragile in this element. As a result of vibrations, the plastic is frayed, rubber o-rings wear out. Often a similar problem can be found on cars with a mileage of over 200 thousand kilometers.

- Rusty pipes, especially at the gas tank inlet. The problem is relevant for cars with high mileage or for cars that have not been used for a long time (more than six months).

- Poor filter or boost pump seal.

- Violation of the tightness of the return line and the injection pump drive shaft.

- Damage to the pump cover and the axis of the diesel feed control lever.

It is possible that the air in the fuel system of a diesel engine (Volkswagen or a car of another brand) enters through the injection pump itself. However, it is better to entrust all diagnostic operations and repairs of this pump to professionals, otherwise there is a risk of incorrect assembly of the mechanism. Among the common causes of air leakage into the fuel system of a diesel engine is a poor-quality filter or its loose fit to the surface. This is the most banal option.

Note that air leakage into the fuel system of a diesel engine appears when both the forward and reverse branches are damaged. Due to the design of the injection pump or the engine, some fuel may remain in the pump, which ensures a good start. However, further work reveals characteristic problems. The engine runs out of fuel and begins to "choke" without it.

How to check?

To make sure that the cause of unstable operation of the engine is air leakage, you need to visually analyze the flow of fuel into the cylinders. To do this, turn the engine with the starter for about 20-30 seconds. So we will fill the exhaust tract with gases, after which we will analyze them. If there is something wrong with the fuel system, a small amount of smoke (usually a gray tint) will come out of the pipe. If the exhaust has a bluish-gray tint, then a large amount of oil enters the combustion chamber.

Second method

Another easy way to diagnose air leaks in the fuel system of a diesel engine is to examine the marks under the bottom of the car. If afterafter several hours of inactivity, oily drops formed on the floor in the garage or on the asph alt, which means that there is a breakdown somewhere. But it often happens that there are no leaks and it is almost impossible to find air leakage in the diesel fuel system in this way.

Professional diagnostic methods

The classic way to check the tightness of this system is with compressed air. This will require a small amount of fuel and chalk. The last to rub are the pipes and hoses through which the fuel moves. Next, the fuel intake is removed from the tank and the coarse filter is removed. Compressed air is supplied to the fuel intake at a pressure of not more than 0.5 kgf/cm2. At home, this pressure can be taken from a conventional tire chamber or wheel. Next, all pipes and hoses are inspected. Particular attention is paid to the connection points. As practice shows, in 80 percent of cases the reason lies precisely here. In these areas, the chalk will darken as the fuel seeps out.

Please note that damage may also have a "valve" character. That is, air can only enter the system in one direction.

Let's consider another method. For accurate diagnosis of air in the diesel fuel system, it is necessary to disconnect the high-pressure fuel pump from the lines and power it from another container with fuel. Usually a three-liter bottle and two meter-long durite hoses are taken. So that they do not peel off, you also need clamps of the appropriate size.

What's next?

So, disconnect the hoses from the pump and on themplace install recently acquired. We lower their ends into a container with fuel (it is important that it is as clean as possible and without traces of water). We fix the hoses so that they do not move, we start the engine. So we'll find out which of the highways was damaged. It is advisable to replace the deformable element immediately.

At the end of the procedure, we remove air from the fuel chamber of the pump. It is not recommended to simply rotate the starter for this.

How to get rid of air in the system?

No matter how carefully we try to replace the old hose with a new one, there will still be air in the system. But how to remove it correctly? There are several ways to bleed air in a diesel fuel system:

A container with diesel fuel is being prepared. It should be located above the level where the pump is fixed. Then we find the area where there is a “return” fitting for draining fuel. This place should be well washed in order to exclude the ingress of dirt (the diesel fuel system is very sensitive to the slightest specks). Next, the fitting bolt is unscrewed and air is pumped out through the hole. You can pump out with a vacuum pump (a syringe is also suitable). The operation is performed until the fuel itself starts to flow. After that, the bolt is screwed into place, the engine starts

- The fuel supply hose is removed from the injection pump and the air-filled diesel is sucked out until it starts to flow in a dense stream. After the hose is put on the injection pump fittingand crimped with a clamp. Next, the screw of the return line fitting is unscrewed. At the same time, you do not need to pump out the air - it will leave on its own. Next, the motor is started and allowed to run for several minutes to finally get rid of air particles.

- The filter mounting bolt is unscrewed. The last element is not removed. Next, you need to pour a little fuel into the bolt hole. After that, the bolt is screwed into place. Loosen the fitting nut on the second or first nozzle. Then you need to start the engine. when the diesel starts to splash from under the nozzle nuts, they must be screwed back. This method is relevant if the cause of suction was a loose fit of the filter itself.

These are the main ways to remove air from the system. Please note that air may be present even with serviceable fuel lines and other elements. It is enough to drive some distance on a "dry" tank. Air will automatically be sucked in by the pump, and then flow to the nozzles. Do not bring the car to such a state. It is advisable to refuel the car no later than the lamp on the instrument panel lights up.

Could the choke be elsewhere?

It should not be ruled out that air can enter through other places into the engine. So, after diagnosing the fuel hoses, you should pay attention to the intake manifold.

Thus, oxygen unaccounted for by sensors (mass air flow or absolute pressure) penetrates into the engine along with fuel,which is the cause of the unstable operation of the internal combustion engine. Among the reasons, experts identify:

- Overheating, resulting in a violation of the tightness of the gaskets.

- Mechanical impact (for example, inaccurate repairs).

- Exposure to carburetor cleaners. This is a very caustic agent that not only cleans the dirt in the intake manifold, but also corrodes all rubber elements, including sealant.

The hardest thing is to find the leak between the intake manifold and the engine cylinder head. Also, oxygen can penetrate due to poor sealing of the nozzles or damage to the air ducts. Let's consider what methods can be used to detect a problem if it does not occur in the fuel line:

- When oxygen enters the path after the flow meter, you should unscrew the air pipe with the sensor from the filter housing and start the engine. At the same time, the part with the sensor is closed by hand. If there is no suction, the motor should stall. If the engine continues to run, then there is air in the diesel fuel system (Renault Kangoo is no exception). In this case, the “sick” area will emit a characteristic hiss. The place of air leakage into the fuel system of a diesel engine must be sought by ear.

- You can diagnose the problem by spraying probable places with mixtures like WD-40. It is necessary to spray on the rubber tube from the flowmeter to the valve cover. They also spray the place where the block head connects to the intake manifold. Another area - injector gaskets.

About the smoke generator

A more professional diagnostic method is to use a smoke generator. But such a unit is often only available at service stations. The essence of the diagnosis is simple: first, smoke is launched into the intake tract, and then they look from which places it went out, not reaching the valve cover.

Where else to look for the cause? Buck

If the diagnostics did not give results and the fuel injectors, filter, pump are in good condition, it can be stated that air has entered through the fuel tank. But in such a situation, it is better to seek help from a service station, since it will be very difficult to check the tank for leaks with your own hands.

Conclusion

So, we looked at why air appears and how to get rid of it with our own hands. As you can see, it is quite possible to eliminate air leakage from the diesel fuel system, but if the cause is serious (as we noted, this is a malfunction of the high-pressure fuel pump itself or a problem with the tank), you cannot do without the help of specialists.

Recommended:

Oil pressure light on at idle: troubleshooting and troubleshooting

What should a driver do when he sees the idle oil pressure light on the dashboard? Beginners may be interested in a similar question, while experienced owners turn off the engine first. This is due to the fact that further work of the power unit can end very badly for it

Air intake on the hood - for whom there is an overlay, for whom an effective ventilation and cooling system

On many cars today you can see the air intake installed on the hood. In this regard, the question arises of what is the need for such a refinement of the machine

Oil gets into antifreeze: causes, consequences, solutions

The engine is the foundation of any car. The internal combustion engine uses many mechanisms and systems. Each of them has its own function and purpose. So, an integral part of the engine is the cooling and lubrication system. In the first case, antifreeze is used, in the second - oil. These liquids have completely different purposes and composition. It is unacceptable that they mix with each other. But sometimes problems happen, and the oil gets into the antifreeze. The reasons for this phenomenon may be different

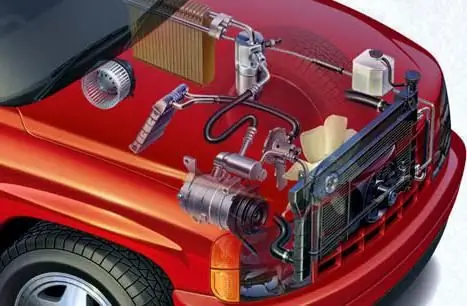

Car air conditioning system: diagnostics, repair, flushing, cleaning, system pressure. How to flush a car's air conditioning system?

The warm season is accompanied by frequent requests from car owners to service shops for such a service as diagnostics of the car's air conditioning system, as well as troubleshooting. We will understand the reasons for this phenomenon

Troit the Priora engine (16 valves): causes and troubleshooting. How to check the spark plugs and ignition coil "Lada Priora"

Despite the huge amount of criticism against the Lada Priora, this is one of the most popular cars that have come off the AvtoVAZ assembly line in recent years. "Priora" is equipped with a fairly successful engine with good dynamics, the interior turned out to be very comfortable. And in the maximum trim levels useful options are offered. But at the same time, from time to time, the car brings minor problems to the owners. One of the most popular malfunctions is the Priora engine troit (16 valves)