2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:14

Nothing upsets a car enthusiast more than dents in a shiny new car body. And getting this trouble is easy. For example, during an unsuccessful parking or simply getting into an accident. Or, in general, waking up in the morning and going outside to your car, you can see dents on its body. True, some drivers do not pay attention to such damage. As they say: “Straightening is time, money, but the car drives, it doesn’t affect the speed, well, okay.” “Okay”, this is when the dent is still small and the paintwork is not damaged. In another case, such negligence will lead to the appearance of rust, corrosion, and in the future the entire body of the car may become completely unusable. Therefore, it is better, without delay, to do a dent repair in order to avoid further problems.

Basic concepts of straightening work

It is worth noting right away that it is not at all easy to straighten damage to the body on your own. First, you need to have a certain set of knowledge,how it's done. Secondly, practical experience of these works is needed, and, thirdly, high-quality straightening is extremely carefully carried out body repair work. In another case, instead of fixing a small dent on the wing, you can get a deformation of most of its surface, and then it will be easier to replace it, rather than repair it, which will cost completely different money. Based on the size and complexity of the damage, the way they are repaired varies. For example, if the damage is small, they start to fix it from the middle, and then the edges are brought up. If repair of larger dents is required, then they begin to align, on the contrary, from the edges and gradually reduce to the middle. With a large deformation and slight damage to the paintwork, some experts heat the metal before straightening. But without experience, this is not recommended, since the metal can be overheated, due to which it will lose its properties or even melt.

Necessary set of tools for straightening

To carry out body work of any complexity, you will need a special tool for straightening the car body.

Hammer set:

- flat-faced;

- with a thin dotted striker;

- with a round striker;

- with special notches;

- smoothing.

In addition to hammers, spot welding of the body will require a spotter, special straightening files, straightening hooks and small anvil support elements.

It is clear thatthis list is far from complete. In various cases, additional sets of tools and devices may be required, for example, hydraulics for straightening, etc. The above list of tools can be considered the basic set that every motorist who prefers to repair his car on his own whenever possible can be considered.

Vacuum body straightening

Just a dozen or a year and a half ago, such a thing as vacuum straightening could look like a science fiction section. In those days, all straightening work was done by hand, and after that the body was polished, primed and painted. Now, thanks to the advent of special devices equipped with a vacuum suction cup, this simple and convenient method has become a reality. Aligning a car in this way is extremely simple. A suction cup is fixed in the center of the dent and pulled out with a slight movement of the hand. The advantage of this method is that the paintwork of the car is not damaged. This straightening is an advantage over other dent repair methods because it does not require the body to be dismantled to gain access to the inside of the damaged part. This method can be easily applied to the entire surface of the car. Unfortunately, it is impossible to completely get rid of the dent in this way, but visually one hundred percent effect of its absence is obtained. Large shallow dents with smooth geometry are corrected very well. It is not advisable to use this method if the dents are chipped andcracks, even if they are small. It's just that in this case the surface is deformed even more, and additional costs will be required to correct them.

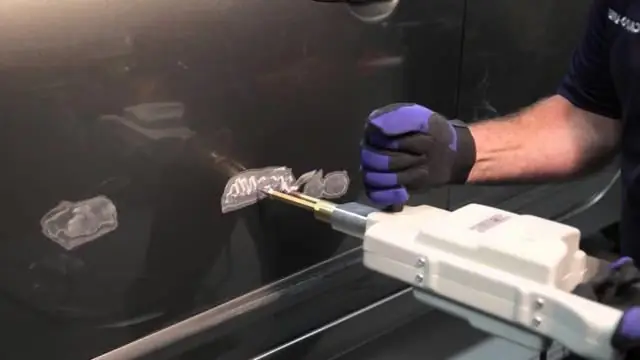

Dent pulling with hook method

This method is more laborious than the previous one. It is used already with more significant damage to the surface of the body. Such straightening can be done in two ways. The first way, it can also be called "barbaric" is when a self-tapping screw is screwed into the body of the car, and the dent is pulled out with the help of an inertial hammer. After removing the dent, the hole from the self-tapping screw is puttied, and the surface is ground, primed and painted. The second option is when, instead of a self-tapping screw, pieces of thin wire are welded to problem areas using the point method and a dent is also pulled out with its help. After completion, the surface is also primed, sanded and painted.

Percussion straightening

The highest quality straightening is just a method of body repair by tapping. This method is even more complex than straightening by pulling. The car body is being dismantled. The damaged part is removed, the area of the dent is marked on the reverse side, and its area is carefully leveled by lightly tapping the hammer. From the outside, it is necessary to put an emphasis, or better, a special anvil. In some cases, it is advisable to heat the metal in the dent zone, making it softer and more pliable. The huge advantage of this type of straightening is that you canrepair almost any dent, crack and other damage. And the correction will be not only visual, but until the dent is completely eliminated. But there is also a big downside. In order for such work to be carried out with really high quality, a very large practical experience is required, and a beginner, no matter how hard he tries, cannot do such work.

Surface protection

After the defect of the body is straightened and restored to its original form, in order to avoid rust and corrosion, as a result of which the body may become unusable, the repaired surface must be protected from the external environment. To do this, the surface is polished with fine sandpaper, and preferably with a grinding wheel. Then the cleaned surface is puttied, after the putty dries, the surface is primed and, finally, painted.

Recommended:

Installing a body kit on a car. Installing an aerodynamic body kit

Installing a body kit on a car can be decorative or perform certain functions. The installation of aerodynamic body kits helps to create artificial downforce, thereby facilitating driving and increasing its dynamic performance

Do-it-yourself car body straightening: technology, features and reviews

The article is devoted to self-straightening of the body. The technology of the operation, the types of work, as well as the reviews of the performers themselves are considered

Car jack - an indispensable tool for any driver

A car jack is exactly the thing that all drivers need so much! There are several types. When choosing a jack, you need to consider the weight and dimensions of your car

Tuning "Nissan-Maxima A33". Chip-tuning of the engine, fine-tuning of the interior. External body changes, body kit, wheels, headlights

Versions in the maximum configuration are equipped with large 17-inch wheels, an electric sunroof, a climate control system, leather seats, heated rear-view mirrors and automatic folding. You can list all the options endlessly, because "Maxima" belongs to the business class and fully corresponds to the assigned level

G12 antifreeze - a tool that extends the life of the car

G12 antifreeze is an excellent development of German chemists working in the automotive direction in science. Its service life and functional qualities are ideal for modern cars