2026 Author: Erin Ralphs | [email protected]. Last modified: 2025-01-22 21:14:11

A compressor is required for the ZIL-130 brake system. The principle of operation of the modification is based on air injection. This happens in a closed pneumatic system. The device of this series is installed to the right of the motor. In order to disassemble the ZIL-130 compressor in detail, the technical characteristics must be considered. However, first of all, it recommends that you familiarize yourself with the device of the mechanism.

ZIL-130 compressor: device and operation of the model

The principle of operation of the compressor is built on the pumping of air. This is achieved through the movement of the pistons. The standard modification includes a wired crankcase that has channels. There is an oil seal in the central chamber of the system. A spring is installed to operate the supercharger. To prevent damage to the compressor from high pressure, there is a seal. A rod is also involved in the device. When it is retracted, air enters the valve.

Detailed modification parameters

The ZIL-130 compressor has the following specifications: working volume - 214 cubic meters. centimeters, the capacity is 210 liters. The power consumption of the presented modification is no more than 2.1 kW. Limitingthe rotational speed is 2 thousand revolutions per minute. Inside the pneumatic system, the pressure is maintained at around 740 kPa. The ZIL-130 compressor costs (market price) 22 thousand rubles

Crankcase Modification

The crankcase on the ZIL-130 air compressor is installed with a rocker arm. Directly in front of the device there is a special shaft. As a rule, it is lubricated only at the base. The main problem of the crankcase lies in the wear of the struts. To correct this situation, you can disconnect the plug. Next, you need to inspect the drive shaft. To replace the crankcase, the cover is completely removed. If there is a problem with the shaft, only the front part of the rocker is disconnected.

Injection mechanism

The injection mechanism in the device is made in a very compact size. According to experts, the device can withstand high pressure. Thus, the price for the ZIL-130 compressor is quite justified. The saddle in the device has two outputs. The specified part does not come into contact with the rocker.

The injection mechanism is connected to the crankcase through a tube. The shaft of the model uses a small diameter. At its base there are two rings and lubricant for the ZIL-130 compressor. A short plug is installed at the end of the shaft. The exhaust valve at the supercharger is used with a protective sleeve. If there are problems with the air supply, the blower outlet is checked first. Next, the cap is unscrewed and the valve is completely cleaned. The next step, experts recommend checking the spring, because itthere is a lot of pressure.

Device crankshaft

The crankshaft in this case is connected to the crankcase. The outlet channel is used with a small diameter. Cylinders on the ZIL-130 compressor are installed on the sides. It should also be noted that there are two overlays on the underside of the modification. The shaft is fixed on the clamp. Additional attention deserves the fact that the guides of this compressor are installed on the left side. When the shaft is shorted, experts recommend inspecting the supercharger completely.

The crankcase is also checked, as it usually collects all the debris from the recycled oil. For the correct operation of the system, the pressure inside the unit is tested. It is also necessary to immediately clean all channels from the crankcase. This can be done using an ordinary ramrod. The seat is pre-lubricated. If the shaft is deformed, it must be replaced immediately. For spare parts ZIL-130 prices are quite reasonable. The tip of the part is welded on by hand.

Plunger mechanism

The plunger mechanism of this compressor is used with a bearing row. Experts say that the part is able to withstand heavy loads at significant speeds. However, it is important to consider that the inlet valve needs to be cleaned frequently. In this case, the channel is quite often clogged. To check it, the crankcase is unscrewed. You will also have to remove the cover. An adjusting screw is used to adjust the plunger. When taking off, the lining can be installedbig screw. In this case, it is necessary to select the appropriate protective ring. To solve problems with erasing the lining, special means are used to seal the block. Some experts recommend periodically cleaning the tubules.

More motorists may face problems with the plunger base. It is a regular plate, which is fixed on the thread. With a lot of shaking, the connection is broken pretty quickly. As a result, the plate begins to dangle. To correct this situation, it is recommended to first disconnect the cover. After that, it is important to immediately clean the outlet. The screw is loosened very slowly. In this case, you need to monitor the position of the bearing row.

Device seal

The stuffing box on the ZIL-130 compressor is installed with one seal. His camera is small. At the bottom of the modification, two guides are installed. There are racks on the sides of the chamber. It should also be noted that there is one support in the upper part. The crankcase for the ZIL-130 compressor is placed on the right side.

Specialists say that the oil seal does not need frequent maintenance. However, it should be borne in mind that the lining on the support can quickly wear off. In order to inspect them, only the front pillar is removed. Next, it is important to disconnect the block and the stuffing box plate. Then the master will be able to get the lining directly. If small cracks are visible on them, you can try using a sealant. However, specialists with any deformation of partsrecommend replacing them immediately.

Seal replacement

To replace the seal yourself, it is important to carefully inspect the seal. As a rule, it collects a lot of soot. It should also be noted that the seals are erased due to overheating of the pad. This happens due to clogged tubules. To correct this situation, it is recommended to unscrew the protective cover of the compressor. After that, the rings are unscrewed. Then it remains only to push the rocker. New pads are installed on a well-cleaned surface. Prices for new spare parts ZIL-130 are quite adequate.

Saddle Inspection

The seat on the ZIL-130 compressor is installed under the discharge mechanism. To inspect it carefully, you need to remove the front connecting rod. After that, the piston moves directly. The next step is the protective cover. Its plate is fixed with four screws that can be unscrewed with a key. The cork in this case is screwed counterclockwise.

Then it remains only to get to the saddle, which is fixed on the nozzle. There should be an oil seal at the bottom of the device. In this case, the plate is checked separately. It is also worth inspecting the top of the saddle. It often collects soot. You can clean the case with gasoline. In this case, it is important not to damage the rocker.

Plunger repair

If the plunger breaks, repair of the compressor should begin with unscrewing the front crankcase. Further unscrewedprotective cover. After that, it is important to remove the two plates, which are clamped with rings. If they do not loosen, they can be knocked out a little with a hammer. The next step is to inspect the seal. As a rule, a large amount of dirt accumulates on it.

If the supercharger is working properly, then everything inside the block should be clean. In this case, the valves are examined separately. To disconnect the plunger, it is recommended to use a large key. It is problematic to do this on your own due to the fact that it is necessary to constantly hold the piston. In this case, it is better to ask a friend for help.

Recommended:

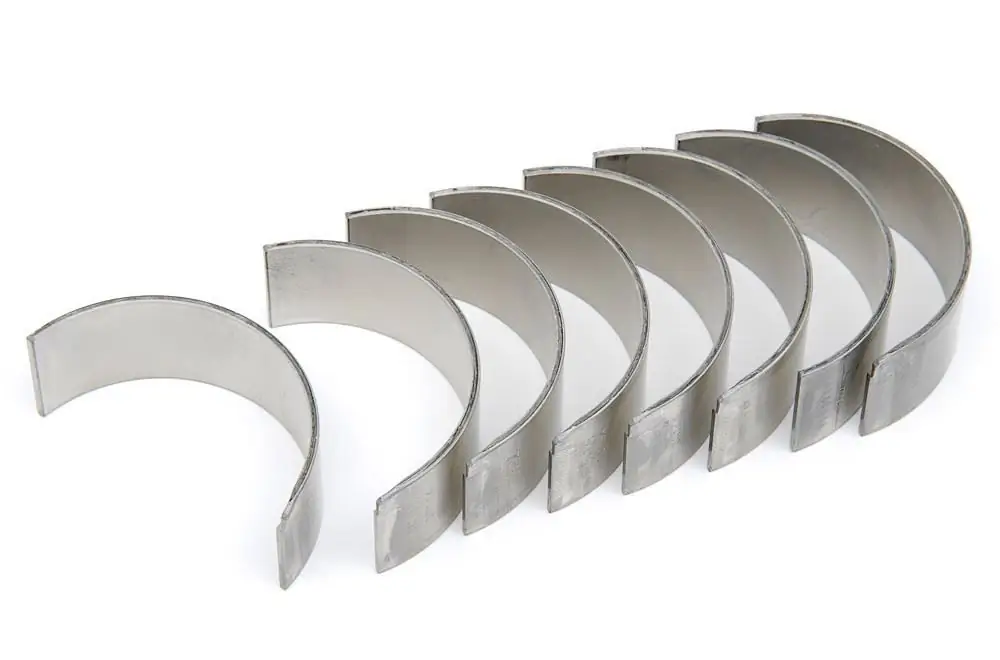

Connecting rod bearing: device, purpose, specifications, features of operation and repair

The internal combustion engine works by rotating the crankshaft. It rotates under the influence of connecting rods, which transmit forces to the crankshaft from the translational movements of the pistons in the cylinders. In order for the connecting rods to work in tandem with the crankshaft, a connecting rod bearing is used. This is a sliding bearing in the form of two half rings. It provides the possibility of rotation of the crankshaft and long engine operation. Let's take a closer look at this detail

Honda Civic Hybrid: description, specifications, operation and repair manual, reviews

In many countries in Europe and Asia, hybrid cars have been the norm for quite some time. They have a whole host of advantages and are in high demand. As for Russia, there are quite a few such machines, although they exist. In this article, we will look at the Honda Civic Hybrid, which has earned a lot of positive feedback from the owners. We will talk about the design features, design and technical component

"KTM 690 Duke": description with photo, technical specifications, engine power, maximum speed, features of operation, maintenance and repair

The first photos of the "KTM 690 Duke" discouraged experts and motorists: the new generation lost its signature faceted shapes and double optical lenses, turning into an almost identical clone of the 125th model. However, the company's press managers diligently assured that the motorcycle had gone through an almost complete update, so it can be considered a full-fledged fourth generation of the Duke model, which first appeared in 1994

Yamaha XT 600: specifications, top speed, operation and maintenance features, repair tips and owner reviews

The XT600, developed in the 1980s, has long been considered a legendary model by the Japanese motorcycle manufacturer Yamaha. A highly specialized enduro over time has evolved into a versatile motorcycle designed to travel both on and off the road

Planetary gearbox: device, principle of operation, operation and repair

Planetary gears are among the most complex gear boxes. With a small size, the design is characterized by high functionality, which explains its widespread use in technological machines, bicycles and caterpillar vehicles. To date, the planetary gearbox has several design versions, but the basic principles of operation of its modifications remain the same