2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:16

It often happens that a strange noise is noticed in the front of the car during its movement, which becomes stronger when accelerating and decreases when stopped. It doesn't matter what gear this happens in, the fault is either with the hub or with the differential bearing. How to change it, regulate it and what it consists of will be discussed in the article.

Differential bearing device

Tapered bearing refers to the type of rolling bearings and is a design consisting of two rings in the form of a truncated cone with running grooves. Between them is a separator with rollers. In shape, they are cylindrical, conical, barrel-shaped, needle-shaped and twisted. Conical in their design are divided into single-row and double-row.

As an element of the mechanism, the differential bearing is capable of operating under conditions of high loads and rotational speeds. Therefore, tapered bearings are part of both axlebox assemblies for railway transport, andhub elements of the vehicle.

Why would a differential bearing need replacing?

Types of defects are divided into the following groups:

1. Initial defects:

- depreciation;

- furrows;

- badass;

- destruction of the surface layer;

- rust;

- result of the passage of electric current.

2. Secondary defects:

- fatigue shells;

- gap.

If there is any defect, intervention will be required. The bearing cannot be repaired, only its replacement is possible.

How are the renovations going?

To carry out restoration activities you will need:

- 2 ball bearings

- Gaskets (oil seals) of drives in the amount of 2 pcs.

- Seal rings. Should be different: right and left.

- Gearbox pan lining.

- Threadlock.

- New gearbox oil.

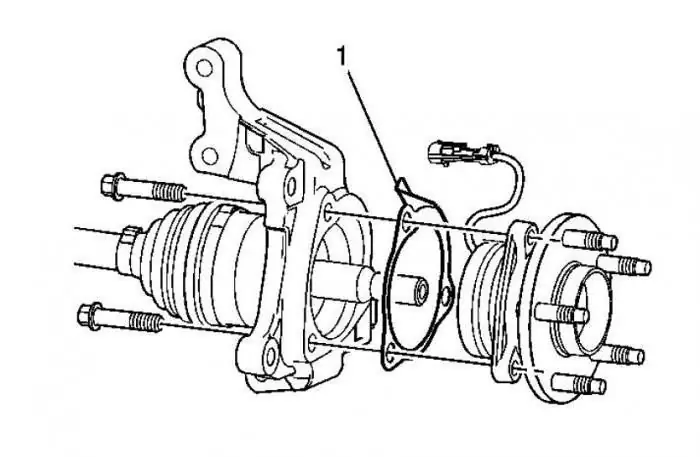

To adjust the differential bearing, you need to remove the gearbox. They are corrected on the dismantled unit with the output shaft gear (key pair) released. After the box has been removed, the differential is removed from it.

The following is done:

- The side gears are released from the differential, rotate 900.

- Using the necessary tool, the retaining ring is removed, which is located in the axis of the gears.

- After remov althe stopper easily gets the axle and, together with it, the gears themselves.

- The head of the required size is taken, the extension cord is taken, then the bolts are unscrewed that secure the driven gear to the differential frame.

- Then the driven gear is released from the housing (you can use a hammer).

Now you need to look at the working surfaces of the parts that were removed for any defects. If small irregularities are detected, they should be eliminated with sandpaper. If there is more serious damage to the parts, it is necessary to replace. Also, if, during inspection, chips, shells or other defects are found on the driven gear, then it is necessary to change it.

Replacement process

The next step is to carefully look at the location of the bearings. If there is a working in these places, the housing should be changed, if shells are found on the tracks and rolling elements, an indentation imprint or a defect in the separators, then the bearings are changed. Then, using a tool, the bearings of the differential are sealed. The outer rings are crimped from the gearbox housing. They do this with a special tool. If there is no puller, then the lapels of the axle shafts are first crimped, then they are replaced with fresh ones.

The outer rings are removed with a beard. Under them there is an adjusting ring. Before compressing them, it is necessary to prepare new copies of the parts. If required, the gear responsible forspeedometer. The differential after changing the bearing is reassembled.

VAZ differential bearing adjustment

Differential - a unit that allows you to split the torque when each of the axle shafts acquires its newtonometers. It also adjusts the speed of rotation of the wheels. When turning, the outer wheel passes through a huge arc and begins to slip. To prevent this, a differential is applied.

Because of him, the wheels have a different angle of torsion at speed. To adjust this element to the condition of the track, it is necessary to adjust the differential.

The elements consist of two parts: the outer rings, which are clamped into the stockings of the bridge; and internal, the ramming of which goes to the differential. You can do the replacement, as well as the adjustment of these nodes, with your own hands.

To adjust differential bearings:

- Loosen the attachment of the bearing caps so that the adjustment nuts can turn.

- These nuts need to tighten the bearing with a little force.

- Tighten the bearings with nuts, turn the gear first in one direction, then in the opposite direction. When this is done, the rollers that are in the bearings are in the desired position.

- To measure the lateral gap in the clutch of the final drive gears on the rear axle housing, you need to strengthen the pointer, bring its probe to the top of the tooth along the outer edge of the gear. The gap should be 0.15-0.2 mm. Measurements must be taken on at least six teeth inreverse crown zones.

- In order to reduce the distance, using a screwdriver or a thin metal rod, the nut for adjusting the edge of the reverse gear is unscrewed, and the other is twisted.

Lapel and inversion of nuts must be carried out by the same amount, orienting them along the grooves. Each spin must be completed with a puff. This action ensures stable contact of the outer ring of the bearing with the nut, which, in turn, serves as a guarantee of fixation during operation. To increase the distance, you need to perform the same steps, but in the opposite order.

Adjustment steps

- After the distance is corrected, it is necessary to check the play on the axle. To do this, a pointer is attached to a tripod, the probe rests against the end of the driven gear. The backlash is measured, and the part sways in the direction of the axis.

- The adjustment nut, which is located on the opposite side of the driven gear, sets the backlash on the axis from 0.055 to 0.035 mm.

- Then the nut is tightened and the preload is set: 0.1 mm, if the bearing mileage is not more than 10 thousand km; 0.05 mm - if more than 10 thousand km. Turning the nut one slot is equal to 0.03 mm “compression” of the bearing.

- After making the adjustment, tighten the bolts on the bearing cap and install the locking plates. The lateral distance is checked again.

Adjustment of UAZ differential bearings

This procedure must be performed by adjusting the thickness of the set of pads for adjustment, which are placed betweenthe sides of the closed rings of both bearings and the gear box. When changing main gear parts and differential bearings, make adjustments in this order:

- Tamp the closed bearing rings on the nut so that there is a distance of 3-3.5 mm between the sides of the gear box and the sides of the closed bearing rings.

- Dismantle the axle shafts and put the differential assembled with the driven gear into the crankcase, install the linings and the cap, do not completely tighten the bolts that hold the covers, and, turning the driven gear with the assembly blade through the crankcase throat, run the bearings in order to make the rollers stood in the right place. Then bolt the cap to the crankcase in the same way and completely.

- Unscrew the bolts. Very carefully remove the cap, remove the differential from the axle housing and use a feeler gauge to measure the distances A and A1 between the sides of the gear box and the closed bearing rings.

- Select a set of pads with a thickness that is equal to the sum of A+A1. To protect the preload in the bearings of the automatic transmission differential, add a 0.1 mm thick gasket to this set. As a result, the total thickness should be A+A1+0.1mm.

- Remove closed differential bearing rings. Break the assembled set of linings into two parts. Put them on the necks of the gear box and tamp the closed bearing rings to the limit. Then correct the distance on the sides by moving the driven gear.

Only after changing differential bearingstake measurements and compare the height of the new and old assembly. If the new bearing is larger or smaller than the obsolete one by a certain amount, then reduce the thickness of the existing set of linings in the first version and make more in the second.

Conclusion

This is how easy it is to adjust and change differential bearings. The article also introduced them to their device and purpose. If you have more complex problems with the differential, it is better, of course, to turn to specialists.

Recommended:

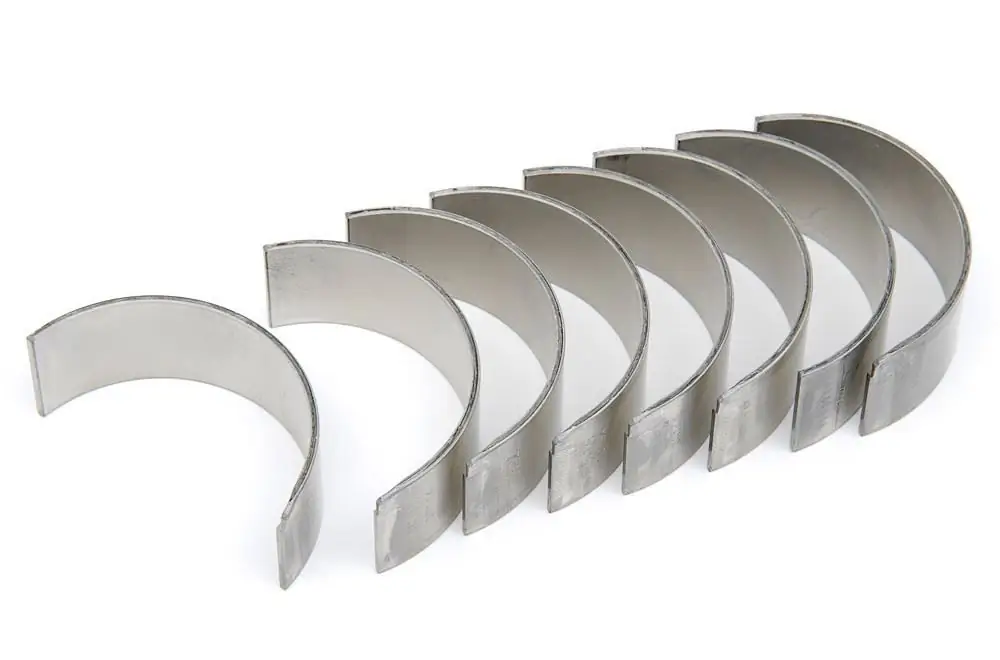

Connecting rod bearing: device, purpose, specifications, features of operation and repair

The internal combustion engine works by rotating the crankshaft. It rotates under the influence of connecting rods, which transmit forces to the crankshaft from the translational movements of the pistons in the cylinders. In order for the connecting rods to work in tandem with the crankshaft, a connecting rod bearing is used. This is a sliding bearing in the form of two half rings. It provides the possibility of rotation of the crankshaft and long engine operation. Let's take a closer look at this detail

Chevrolet Niva front hub bearing replacement. Replacement Tips and Tricks

Did you decide to replace the front hub bearing on the Chevrolet Niva? Then this article is especially for you. Here are tips and tricks for replacing the bearing yourself

Thrust bearing: design, meaning, replacement

Thrust bearing is a small but extremely important part in a car. What is it and why is it needed, it is worth discussing in detail

Front hub design and do-it-yourself bearing replacement

The front hub ensures the wheels turn and rotate around their own axis. This is typical for any car, regardless of the type of drive - front or rear. The only thing that is present in the hubs of cars with front-wheel drive is more powerful bearings, since a CV joint is installed on them

How to properly brew a differential? The principle of operation of the differential. Driving Tricks on a Welded Differential

The device of the car assumes the presence of many nodes and mechanisms. One of these is the rear axle. "Niva" 2121 is also equipped with it. So, the main assembly of the rear axle is the differential. What is this element and what is it for? The principle of operation of the differential, and how to brew it correctly - later in our article