2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:16

Repair work in a car body part usually involves performing technical operations to restore the geometry of the frame. Another type of work, already cosmetic, is aimed at providing the surfaces of the body with the desired decorative effect. The working materials in this case include paintwork, primers and protective pastes. In turn, car putty combines several functions at once, among which protective ones can be noted.

Filling and Finishing Compounds

It rarely happens when the priming mass is applied in one layer. So in the case of automotive plaster - it is divided into two large groups that differ in performance. Actually, the properties of the compositions determine in what sequence this or that composition will be applied. There are two categories of such putties - filling and finishing. The first group includes mixtures that serve as the base foundation for paintwork. These are coarse-grained types of automotive putties that form a rigid mechanical base. The second category, represented by finishing mixtures, is in some way a finishing one, but it should not be confused withdecorative coatings. Its task is to give the already applied coating optimal characteristics for processing with decorative layers. In particular, finishing compounds provide adhesiveness, that is, high adhesion of the surface.

Reinforcing compositions

This is a typical representative of a group of filler fillers, whose list of tasks includes providing mechanical strength to the base coat of the body. A feature of the composition of this mixture is the presence of fiberglass fibers. It is the presence of small threads that creates a platform that is resistant to damage of various kinds on the surface of the car frame. And here it is important to answer the question of how to use automotive putty with fiberglass in the composition. There may be two approaches. The first involves the use of a composition in which plastic fibers are already present. In this case, the master is only required to dilute the mixture with water in the required proportions. However, you can prepare a reinforcing base yourself, using any type of putty as a filler. In this case, it is necessary to additionally purchase a mixture of fiberglass fibers and mix it with the base composition. Next, the resulting mass is applied to the surface according to the type of priming material.

Mixtures for forming a top coat

Coatings of this type are prepared on the basis of fine-grained pastes. As already noted, their function is to prepare the existing surface for further work on decorative layers. The preparation itselfIt consists not only in increasing the adhesion of the filler coating, but also in correcting its minor defects. Do not forget that coarse fiberglass compositions are not ideal in their structure and, in addition to the fibers that stand out, may include large grains. In turn, the finishing automotive putty hides all defects and irregularities, forming a smooth surface of the body. This layer may also require sanding or polishing.

Plastic putty

Unlike metal, plastic requires a more delicate approach in terms of applying protective coatings. To work with such surfaces, manufacturers produce fine-grained pastes with improved adhesion qualities. During the application process, the user forms a thin layer, which can act as a base either for further processing with fillers, or as a final layer before decorative finishing. But it is important to consider that the preparation of such mixtures has its own nuances. The main question in this context is: how to dilute an automotive putty designed for plastic? The base can be water, but, for example, for polyester compositions, it will also be useful to add a 2% hardener. In addition, a degreasing film should be applied to the working plastic surface before processing.

Tips for applying putty

Before processing, the surface of the case is thoroughly cleaned of dirt and traces of rust. Then you can proceed to the composition itself, and only the volume that is guaranteed to be consumed in the next few minutes is prepared for use. The application is carried out with a spatula or even a syringe - the main thing is that thin and neat layers are formed without sharp transitions in thickness levels. Particular attention is paid to additional components with which automotive putty can be diluted. The instruction usually recommends including hardeners and plasticizers, but you should not abuse it with additives. The fact is that modifiers increase some of the working properties of the putty, but reduce others. After processing is completed, the drying process begins, which under natural conditions can last several hours or even days.

Positive feedback on putty

Although the body puttying process seems complicated, once it is completed, the result is more likely to justify the effort. Users highlight two advantages of such mixtures. Firstly, they provide a reliable primer coating with the effect of leveling the surface and eliminating defects. Secondly, the operational protective qualities that automotive putties possess are also noted. Reviews indicate that rust processes and mechanical damage during the use of the machine practically do not affect the metal base treated with putty. That is, a protective shell is formed that does not allow third-party influences of any nature.

Negative reviews

Eat andshortcomings in automotive putties, which can manifest themselves in the most unexpected aspects. For example, there have been cases when users noted a negative effect on the surface of the metal frame from the side of the applied composition. It should be noted here that, most likely, such problems arise due to improper preparation of pastes - for example, due to the high concentration of modifiers introduced. In addition, automotive putty can cause a lot of problems when a major body repair is required with the elimination of all primer coatings.

Conclusion

This kind of coating can be called specialized, because they provide non-standard operational effects. It is enough to note the increased adhesive function, due to which a tight coupling of the paste and metal is formed. The main question relates to how much automotive putty justifies itself from the point of view of an ordinary driver. Of course, the protective properties of such funds show themselves from the best sides, but there are also negative factors that should also be taken into account. In order to strike a balance between the positive and negative nuances of using putty for cars, you should be extremely careful when processing the body using this technique. For example, use thin coats, be careful with the choice of additives and, of course, do not forget about regular maintenance of the surface of the machine already in operation.

Recommended:

Automotive oils 5W30: rating, characteristics, classification, declared qualities, advantages and disadvantages, reviews of specialists and car owners

Every car owner knows how important it is to choose the right engine oil. Not only the stable operation of the iron “heart” of the car depends on this, but also the resource of its operation. High-quality oil protects mechanisms from various adverse effects. One of the most popular types of lubricants in our country is oil with a viscosity index of 5W30. It can be called universal. The 5W30 oil rating will be discussed in the article

Types of car tinting. Car window tinting: types. Toning: types of films

Everyone knows that different types of tinting make the car more modern and stylish. In particular, dimming the windows in a car is the most popular and popular way of external tuning. The whole advantage of such modernization lies in its simplicity and relatively low cost of the procedure

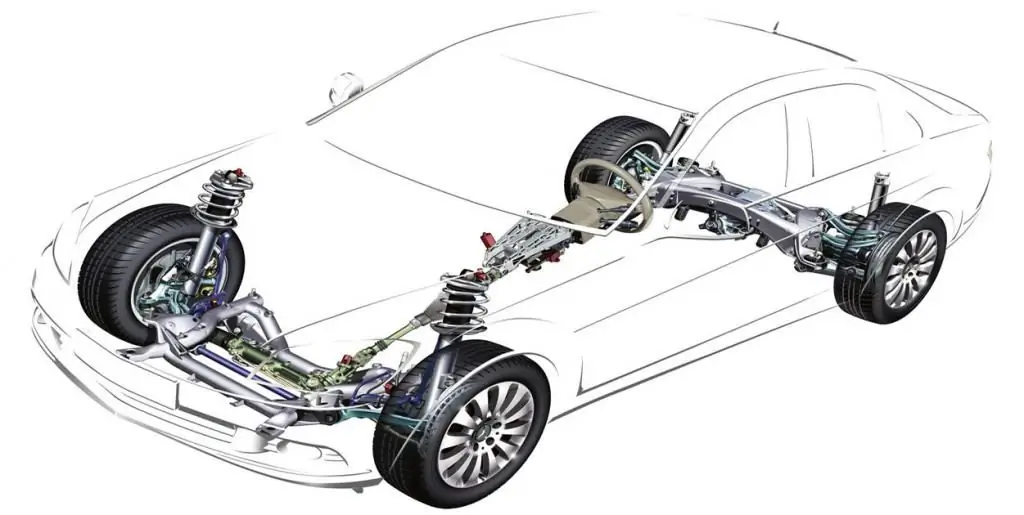

Types of car suspensions: device and diagnostics, features and benefits of various types, reviews

Are many drivers interested in the types of car suspensions? But to know the device of your vehicle, in particular, what parts its chassis consists of, is desirable for certain reasons. This is not only an additional experience, but if necessary, you can take appropriate measures

German automotive oil: types, characteristics, reviews

Engine oil is essential to keep your engine running smoothly. Its replacement is made depending on how many kilometers the car has traveled. We offer a description of German-made oils, which tend to be of high quality. The information provided will help motorists decide on the choice of high-quality lubricant

Automotive primer: types, properties, applications, prices

If the builder has conscientiously treated the creation of the foundation, then the house will serve its owner reliably and for a long time. As for the car, the automotive primer can also be considered the foundation for subsequent paint work. Also, such compounds protect the metal parts of the machine from the harmful effects of corrosion