2026 Author: Erin Ralphs | ralphs@carsalmanac.com. Last modified: 2025-01-22 21:14:09

Grader-elevator is a self-propelled or trailed earthmoving equipment. The continuous machine cuts the soil with a special knife in the process of work, with its further movement by means of a belt conveyor to the dump. Among the features is the low cost of work along with the simplicity of organizing the process compared to similar modifications of other configurations.

Classification of elevator-graders

These machines are divided according to several criteria:

- According to the chassis, mounted, trailers and semi-trailers are distinguished. The most popular are the second and third types. Mounted units are most often paired with heavy wheel graders.

- By the type of working body, spherical disk cutters, a system of flat cutters, a combined design (flat, disk and semicircular pointed knives) are distinguished.

- According to the placement of conveyors. They are located diagonally or transversely. The first versions are used for ground supplyinto trucks. A special thrower is usually used for long-range throwing.

- According to the type of drive. Here are graders-elevators with a mechanical transmission unit powered by an internal combustion engine, as well as multi-engine versions with a diesel-electric unit. The technique in question is equipped with hydraulics or an electro-hydraulic system responsible for controlling the operating body.

Elevator-grader device

The unit under consideration consists of several main units. Among them:

- frame part;

- cutting work item placed on the plunger frame;

- transporter;

- hitch attachment;

- chassis;

- control system;

- hydraulic drive;

- transmission unit;

- engine.

The main frame is designed for mounting all units of equipment, includes a pair of longitudinal square beams in its design. They are interconnected by means of box-shaped corners and profiles. With a tractor, the front part of the frame aggregates using a hitch. The rear assembly rests on wheel axles with pneumatic tires. Working bodies are installed in the middle (a conveyor with a belt and a plunger frame with a knife).

A conveyor is suspended on a part in the form of a rectangular vertical structure and a control system is mounted. It is attached to the main frame by welding. The power plant is mounted on the back of the plate, fixed with a tubular bracket.

ConstructionalFeatures

Elevator graders are most often equipped with disc-shaped cutters mounted on a plunger frame that is welded from three beams. An earring is provided in front of the specified element, and a trunnion resting on the front post is provided at the back.

The deepening of the working body and its return back are carried out by means of a pair of hydraulic cylinders. A rotary feeder with blades can be mounted in front of the conveyor. It serves to change the direction of the feed of the cultivated soil by 90 degrees and then feed it to the belt at a certain speed.

The conveyor block of the grader-elevator is placed on a vertical frame structure, which is pivotally connected to the main frame. Other parts of this assembly include two drums (driven and guide), rollers, tension device, belt, cleaning device. To remove soil from the inner surface of the movable part, there is a cleaning mechanism with an auger. Pollution is mechanically removed from the drum using a scraper.

Travel gear

In this part, the grader-elevator (see photo above) is equipped with a pair of rear wheels on axle shafts. Twin analogues are mounted on them from the side of the conveyor. They are made retractable, which increases the stability of the machine transversely in the working position by adjusting the track width.

Working elements have a drive, aggregating with a tractor engine or one of the engines (diesel or electricity). The torque is applied tosingle-stage gearbox through roller clutches and clutches from the crankshaft. The output part of the driving part of the gearbox activates the gear-configured hydraulic pump.

Application

Assignment of graders-elevators:

- Layer-by-layer cutting of soil with its subsequent supply to the dump. The working distance is up to 15 meters.

- Loading the used composition into dump trucks, trucks.

- Tillage during the construction of roads, dams, embankments, excavations, pits and other objects associated with soil cutting in significant volumes.

- Work in the indicated directions on plains and slightly hilly terrain for the development and pruning of normal soils and low-humidity soils. In this case, there should not be large cobblestones and rocky inclusions. The length of the developed section is from 0.5 to 1.0 kilometers.

The technique in question is used in road, land reclamation and other construction, railway, quarry, in the construction of hydraulic structures. In addition, elevator graders are in demand for stripping and irrigation. Machines are operated at large working volumes, mainly on cohesive soils of the second and third categories.

Finally

Due to the continuous functioning of the working elements of the grader-elevators, an increased performance indicator is guaranteed. At the same time, energy costs, along with the minimum metal consumption, provide a largeefficiency compared to other earthmoving equipment. The power of the machines in question is consumed in terms of productivity almost throughout the entire working period. For comparison, for analogues of the cyclic type, this percentage is only 20-25% (for cutting the ground layer).

The leading economic factors of elevator graders include the rated output (hours) and the transverse and horizontal transport distance of the waste material. This characteristic is taken into account from the knife to the laying point. According to GOST 7125-70, this technique has a performance index of 630 to 1600 cubic meters per hour.

Recommended:

Knuckle "UAZ Patriot": device, characteristics and purpose

Replacing the steering knuckle on the UAZ "Patriot". The device of the steering knuckle on the car UAZ "Patriot". How to remove the steering knuckle on the UAZ "Patriot". Scheme and principle of operation of the steering knuckle on the UAZ "Patriot". How to replace the steering knuckle on a UAZ Patriot car

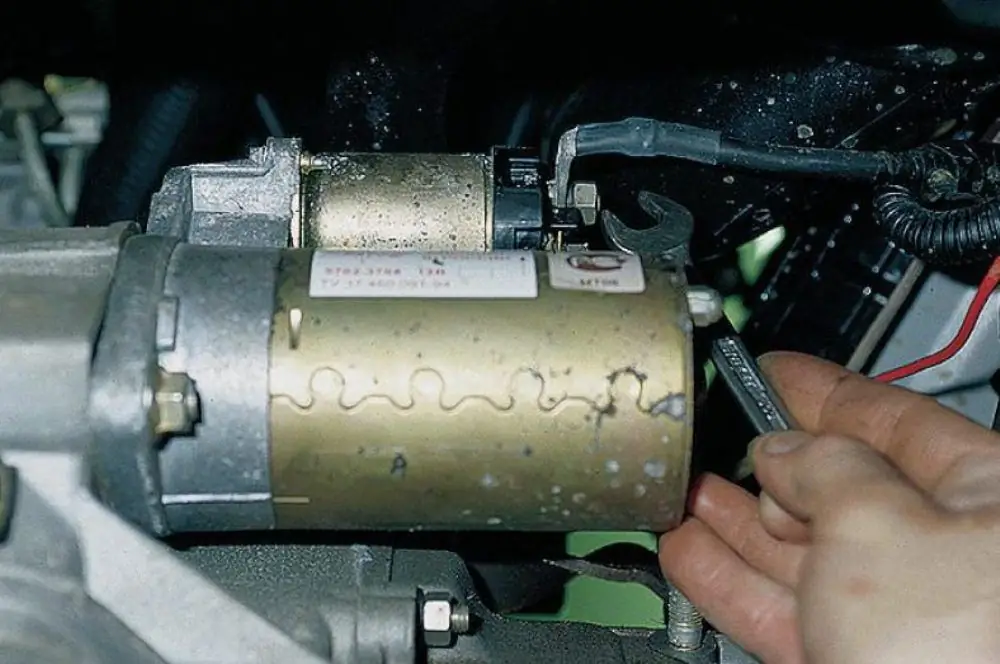

Where is the VAZ-2112 starter relay located? Location, purpose, replacement and device

The starter relay on the VAZ-2112 performs an important function on any car, regardless of model. Failure of this device leads to the fact that the car will not start. Drivers who are engaged in self-repair of the vehicle need to know where this unit is located and how to fix it if any malfunction occurs

Ball pin: purpose, description with photo, specifications, dimensions, possible malfunctions, dismantling and installation rules

When it comes to the ball pin, it means the ball joint of the suspension of the car. However, this is not the only place where this technical solution is applied. Similar devices can be found in the steering, in the guides of the hoods of cars. They all work on the same principle, so the diagnostic and repair methods are the same

Military motorcycles: photo, description, purpose

Military motorcycles: description, history of creation, purpose, modifications, features. Military motorcycles: manufacturers, overview of popular models, photos, interesting facts

"Lazy" on the steering wheel: description, purpose, installation methods, photo

"Lazy" on the steering wheel will help facilitate the process of driving a car. Because it is designed in such a way that you do not need to strain your hands when turning. This is a very handy thing for intensive driving. If you follow all the rules of the road, do not drive at high speed, then such a device will be safe